Cutting Tools Episode 2 Part 9 ppt

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (9.67 MB, 7 trang )

www.toolingandproduction.com

Chapter 18/Tooling & Production

1

2

Tooling & Production/Chapter 18

www.toolingandproduction.com

George Schneider, Jr. CMfgE

Professor Emeritus

Engineering Technology

Lawrence Technological University

Former Chairman

Detroit Chapter ONE

Society of Manufacturing Engineers

Former President

International Excutive Board

Society of Carbide & Tool Engineers

Lawrence Tech www.ltu.edu

Prentice Hall- www.prenhall.com

CHAPTER 18

Lapping and

Honing

Metal Removal

Cutting-Tool Materials

Metal Removal Methods

Machinability of Metals

Single Point Machining

Turning Tools and Operations

Turning Methods and Machines

Grooving and Threading

Shaping and Planing

Hole Making Processes

Drills and Drilling Operations

Drilling Methods and Machines

Boring Operations and Machines

Reaming and Tapping

Multi Point Machining

Milling Cutters and Operations

Milling Methods and Machines

Broaches and Broaching

Saws and Sawing

Abrasive Processes

Grinding Wheels and Operations

Grinding Methods and Machines

Lapping and Honing

Upcoming Chapters

FIGURE 28.1: Typical lapping machine.

(Courtesy Engis Corp.)

18.1 Introduction

Lapping is a final abrasive finishing operation that produces extreme

dimensional accuracy, corrects minor imperfections of shape, refines

surface finish, and produces close fit between mating surfaces. Most

lapping is done with a tooling plate or wheel (the lap), and fine-grained

loose abrasive particles suspended in a viscous or liquid vehicle such as

soluble oil, mineral oil, or grease. A typical lapping operation is shown in

Figure 18.1.

Honing is a low velocity

abrading process. Material

removal is accomplished at

lower cutting speeds than in

grinding. Therefore, heat

and pressure are minimized,

resulting in excellent size

and geometry control. The

most common application of

honing is on internal cylin-

drical surfaces. The cutting

action is obtained using

abrasive sticks mounted on a

metal mandrel. Since the

work is fixed in such a way

as to allow floating, and no

clamping or chucking, there

is no distortion.

18.2 Lapping Processes

The principal use of the lapping

process is to obtain surfaces that are

truly flat and smooth. Lapping is also

used to finish round work, such as

precision plug gages, to tolerances of

0.0005 to 0.00002 inches.

Work that is to be lapped should be

previously finished close to the final

size. While rough lapping can remove

considerable metal, it is customary to

leave only 0.0005 to 0.005 inches of

stock to be removed.

Lapping, though it is an abrasive

process, differs from grinding or hon-

ing because it uses a ‘loose’ abrasive

instead of bonded abrasives like grind-

ing wheels (Fig. 18.2).

These abrasives are often purchased

‘ready mixed’ in a ‘vehicle’ often made

with an oil-soap or grease base. These

vehicles hold the abrasive in suspen-

sion before and during use. The paste

abrasives are generally used in hand-

lapping operations. For machine lap-

ping, light oil is mixed with dry abra-

sive so that it can be pumped onto the

lapping surface during the lapping op-

eration.

18.2.1 Lapping Machines

These machines are fairly simple

pieces of equipment consisting of a

rotating table, called a lapping plate,

and three or four conditioning rings.

Standard machines have lapping plates

www.toolingandproduction.com

Chapter 18/Tooling & Production

3

Chap. 18: Lapping and Honing

from 12 to 48 inches in diameter. Large

machines up to 144 inches are made. 1

to 20 HP motors run these tables. A

typical lapping machine is shown in

Figure 18.3.

The lapping plate is most frequently

made of high-quality soft cast iron,

though some are made of copper or

other soft metals. This plate must be

kept perfectly flat. The work is held in

the conditioning rings. These rings ro-

tate as shown in Fig. 18.4. This rotation

performs two jobs. First it ‘conditions’

the plate, that is, it distributes the wear

so that the lapping plate stays flat for a

longer time. Secondly, it holds the

workpiece in place. The speed at which

the plate turns is determined by the job

being done. In doing very critical

parts, 10 to 15 RPM is used, and when

polishing, up to 150 RPM is used.

one step. Also, less time is required for

cleaning parts and processing waste;

throughput, along with overall produc-

tivity, is increased.

Lapping plates are manufactured

from various materials as described

below, and are available in standard

sizes from 6 to 48 inches in diameter.

Plates are supplied with square, spiral,

and concentric and radial grooves as

shown in Figure 18.5.

Iron - Aggressive Stock Removal:

• Excellent primary/roughing lap

plate, with long service life

• Often used as an alternative to

cast iron plates

• Produces a good surface finish on

most materials, especially metals and

ceramics.

Copper - Moderate to Aggressive

Stock Removal:

• Most widely used, universal com-

posite lap plate

• Excellent when primary and fin-

ishing lap are combined in a one step

operation

• Suitable for virtually any solid

material: metal, ceramic, glass, car-

bon, plastic, etc.

Ceramic - Moderate Stock Removal:

• Generally used to lap/polish ce-

ramic parts and other stain- sensitive

materials.

• Used in applications where metal-

lic-type contamination cannot be tol-

erated

• Affordable, more machinable al-

ternative to ‘natural’ ceramic plates.

Figure 18.3. Typical dual plate lapping ma-

chine. (Courtesy Engis Corporation)

Figure 18.2. Abrasive grit must be uniformly graded to be effective

in lapping.

Workpiece

Lap

A pressure of

about 3 pounds

per square inch

(PSI) must be ap-

plied to the

workpieces.

Sometimes their

own weight is suf-

ficient. If not, a

round, heavy pres-

sure plate is

placed in the con-

ditioning ring. The larger machines use

pneumatic or hydraulic lifts to place

and remove the pressure plates. Figure

18.5 shows various lapping plates.

The workpiece must be at least as

hard as the lapping plate, or the abra-

sive will be charged into the work. It

will take from 1 to 20 minutes to

complete the machining cycle. Time

depends on the amount of stock re-

moved, the abrasive used, and the qual-

ity required. Figure 18.6 shows a pro-

duction-lapping machine.

18.2.2 Grit and Plate Selection

Flatness, surface finish, and a pol-

ished surface are not necessarily

achieved at the same time or in equal

quality. For example, silicon carbide

compound will cut fast and give good

surface finish, but will always leave a

‘frosty’ or matte surface.

The grits used for lapping may occa-

sionally be as coarse as 100 to 280

mesh. More often the ‘flour’ sizes of

320 to 800 mesh are used. The grits,

mixed in slurry, are flowed onto the

plate to replace worn-out grits as the

machining process continues.

The case for using diamond super

abrasives rather

than conventional

abrasives such as

aluminum oxide

or silicon carbide

can be summed

up in three words.

Diamonds are

faster, cleaner,

and more cost-ef-

fective.

With diamond

slurries, the lap-

ping and polish-

ing phases of a

finishing opera-

tion can often be

combined into

Figure 18.4. Conditioning rings used in lapping operations.

4

Tooling & Production/Chapter 18

www.toolingandproduction.com

Chap. 18: Lapping and Honing

Tin/Lead - Fine Stock Removal:

• Most widely used finishing lap/

polishing plate

• Often used in place of polishing

pads

• Suitable for metal, ceramic and

other materials.

Tin - Fine Stock Removal

• Often used where lead-type con-

tamination cannot be tolerated

• Suitable for charging of extra-fine

particulates.

18.3 Advantages and Limitations

Any material, hard or soft, can be

lapped, as well as any shape, as long as

the surface is flat.

Advantages: There is no warping,

since the parts are not clamped and

very little heat is generated. No burrs

are created. In fact, the process re-

moves light burrs. Any size, diameter,

and thickness from a few thousandths

thick up to any height the machine will

handle can be lapped. Various sizes

and shapes of lapped parts are shown

in Figure 18.7.

Limitations: Lapping is still some-

what of an art. There are so many

variables that starting a new job re-

quires experience and skill. Even

though there are general recommenda-

tions and assistance from the manufac-

turers, and past experience is useful,

trial and error may still be needed to

get the optimum results.

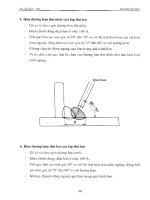

18.4 Honing Processes

As stated earlier, honing is a low

velocity abrading process. Material re-

moval is accomplished at lower cutting

speeds than in grinding. Therefore,

heat and pressures are minimized, re-

sulting in excellent size and geometry

control. The most common application

of honing is on internal cylindrical

surfaces. A typical honing operation is

shown in Figure 18.8.

Machining a hole to within less than

0.001 inch in diameter and maintain-

ing true roundness and straightness

with finishes less than 20 u inches is

one of the more difficult jobs in manu-

facturing.

Finish boring or internal grinding

may do the job, but spindle deflection,

variation in hardness of the material,

and difficulties in precise work hold-

ing, make the work slow and the re-

sults uncertain. Honing, because it

uses rectangular grinding stones in-

stead of circular grinding wheels, as

shown in Figures 18.9a and 18.9b, can

correct these irregularities.

Honing can consistently produce

finishes as fine as 4 u inches and even

finer finishes are possible. It can re-

move as little as 0.0001 inch of stock

or as much as 0.125 inch of stock.

However, usually only 0.002 to 0.020

inch stock is left on the diameter for

honing. As shown in Figure 18.10,

honing can correct a number of condi-

tions or irregularities, left by previous

operations.

18.5 Honing Machines

For most work, honing machines are

quite simple. The most used honing

machines are made for machining in-

ternal diameters from 0.060 to 6

inches. However, large honing ma-

chines are made for diameters up to 48

inches. Larger machines are some-

times made for special jobs.

The length of the hole that can be

honed may be anything from 1/2 inch

to 6 or 8 inches on smaller machines,

and up to 24 inches on larger ma-

chines. Special honing machines are

made which will handle hole lengths

up to 144

18.5.1 Horizontal Spindle Machines

Horizontal-spindle honing ma-

chines, for hand-held work with bores

up to 6 inches, are among the most

widely used. The machine rotates the

hone at from 100 to 250 FPM.

Figure 18.5. Typical lapping plates. (Cour-

tesy Engis Corporation)

Figure 18.7. Various sizes and shapes of lapped

parts. (Courtesy Engis Corporation)

Figure 18.8. Typical vertical honing operation.

(Courtesy Sunnen Products Co.)

Figure 18.6. Single plate lapping produc-

tion machine equipped for diamond abrasive

slurry use. (Courtesy Engis Corporation)

www.toolingandproduction.com

Chapter 18/Tooling & Production

5

Chap. 18: Lapping and Honing

The machine operator moves the

work back and forth (strokes it) over

the rotating hone. The operator must

‘float’ the work, that is, not press it

against the hone or the hole will be

slightly oval. Sometimes the work-

piece must be rotated.

Horizontal-spindle honing machines

are also made with ‘power stroking’. In

these, the work is held in a self-align-

ing fixture and the speed and length of

the stroke are regulated by controls on

the machine.

As a hone is being used, it is ex-

panded by hydraulic or mechanical

means until the desired hole diameter

is achieved. Various mechanical and

electrical devices can be attached to

the honing machine to control the rate

of expansion, and stop it when final

size is reached.

On the simplest hand-held ma-

chines, the operator may check the

bore size with an air gage, continue

honing, recheck, etc. until the size is

correct. A horizontal-spindle honing

machine is shown in Figure 18.11.

18.5.2 Vertical Spindle Machines

Vertical-spindle honing machines

are used especially for larger, heavier

work. These all have power stroking at

speeds from 20 to 120 FPM. The

length of the stroke is also machine

controlled by stops set up by the

operator.

Vertical honing machines are also

made with multiple spindles so that sev-

eral holes may be machined at once, as

in automobile cylinders (Figure 18.8).

Hone Body: The hone body is made

in several styles using a single stone

for small holes, and two to eight stones

as sizes get larger (Fig. 18.9b). The

stones come in a wide variety of sizes

and shapes. Frequently there are hard-

ened metal guides between the stones

to help start the hone cutting in a

straight line.

Cutting Fluid: A fluid must be used

with honing. This has several pur-

poses: to clean the small chips from

the stones and the workpiece, to cool

the work and the hone, and to lubricate

the cutting action.

A fine mesh filtering system must

be used, since recirculated metal can

spoil the finish.

A vertical honing operation was

shown in Figure 18.8. A few of the

parts honed on such a machine are

shown in Figure 18.12.

18.6 Abrasive Tool Selection

The abrasive honing stone must be

selected for the proper abrasive type,

bond hardness and grit size to deliver

the fastest stock removal and desired

surface finish. This selection is simple

if done in the following three steps:

Step One: Select the abrasive type

with respect to the material composi-

tion of the bore. There are four differ-

ent types of abrasives: aluminum ox-

ide, silicon carbide, diamond, and

CBN. All four of these were discussed

in the previous chapter. Each type has

its own individual characteristics that

make it best for honing certain materi-

als. Some simplified guidelines for

their use are:

• Mild steel hones best with alumi-

num oxide.

• Cast iron, brass, and aluminum

hone best with silicon carbide.

• Glass, ceramic, and carbide hone

best with diamond

• High speed tool steels, and super

alloys hone best with CBN.

Mandrel

Honing shoe

Honing stone

Workpiece

(a)

Figure 18.9a. Schematic illustration of the com-

ponents of an internal hone.

Figure 18.9b. Typical honing tool is shown be-

ing Checked (Courtesy: Gehring L.P.)

Alignment of tandem holes

Correcting bellmouth

Correcting taper

Correcting rainbow-shaped holes

Figure 18.10. Undesirable conditions that can

be corrected by honing.

6

Tooling & Production/Chapter 18

www.toolingandproduction.com

Chap. 18: Lapping and Honing

Diamond and CBN are considered

super abrasives because they are much

harder than conventional abrasives.

They cut easily and dull slowly, there-

fore allowing them to hone certain

materials much faster and more effi-

ciently than conventional abrasives.

However, as shown above, super abra-

sives are not suited to honing all mate-

rials. For instance, diamond does not

hone steel very well, and CBN may not

be as economical as using aluminum

oxide to hone soft steel.

Step Two: Use the stone hardness

suggested in the manufacturer’s cata-

log. If the stone does not cut, select the

next softer stone; if the stone wears too

fast, select the next harder stone. Stone

hardness does not refer to the hardness

of the abrasive grain, but to the

strength of the bonding material hold-

ing the abrasive grains together, as

discussed in the previous chapter. A

bond must be strong enough to hold

sharp abrasive grains in position to cut,

but weak enough to allow dulled grains

to be sloughed off to expose underly-

Figure 18.13. Plateau honed finish surface at 100x (Cour-

tesy: Gehring L.P.)

Figure 18.12. Parts honed on a vertical honing ma-

chine. (Courtesy Sunnen Products Co.)

Figure 18.11. Horizontal-spindle honing

machine (Courtesy Sunnen Products Co.)

ing sharp grains. If the bond is too

hard, the dulled abrasive grains will

not be allowed to fall off, and the stock

removal rate will be reduced. If the

bond is too soft, the stone will wear

excessively because sharp abrasive

grains fall off before they are fully

used.

Diamond and CBN abrasive grains

dull so slowly that standard ceramic or

resin bonds may not be strong enough

when honing rough out-of-round bores

in hard materials, or when CBN is used

to hone soft steel. Metal bonds are best

suited for these applications because

the grains are held in a sintered metal

matrix that is much stronger than stan-

dard bonds. As with choosing abrasive

type, stone bond hardness must be

matched to the application to maxi-

mize life and stock removal rates.

Step Three: Select the largest abra-

sive grit size that will still produce the

desired surface finish. Surface finish is

a function of the height of microscopic

peaks and valleys on the bore surface

and honing can produce al-

most any degree of rough-

ness or smoothness through

the use of different abrasive

grit sizes.

Honing oil can improve

stock removal rates by help-

ing the cutting action of the

abrasive grains. It prevents

pickup (spot welding of tool

to bore) and loading (chips

coating the stone). Honing

oil does this, not by acting as

a coolant, but through

chemical activity. The ingredients in

the oil produce this chemical activity.

Whenever the temperature rises at one

of the microscopic cutting points, the

sulfur in the oil combines with the iron

in the steel to form iron

sulfide, an unweldable

compound, and weld-

ing is prevented. The

antiwelding property of

honing oil also pre-

vents chips from stick-

ing together and coat-

ing the stone. Water

based coolants cannot

produce this type of

chemical activity. Use

of water-based coolants

will result in welding

of metallic guide shoes

to the part and loading of vitrified

abrasive honing stones.

18.7 Cylinder Block Honing

Bores sometime require a prelimi-

nary rough honing operation to remove

stock, followed by finish honing to get

the desired surface finish. A character-

istic feature of a honed surface finish

is crosshatch, which makes an excel-

lent oil retention and bearing surface.

The crosshatch pattern is generated in

the bore surface as the workpiece is

stroked back and forth over the rotat-

ing honing tool.

Plateau Honing: A few years ago a

special surface finish generated inter-

est in the engine rebuilding market.

With this finish, the valleys are deep

and the peaks have been removed to

form plateaus, giving the name plateau

honing or plateau finish as shown in

Figure 18.13. A recent test by a ring

manufacturer has shown that an engine

with a true plateau finish consumed

one-tenth the oil and had 80 percent

less cylinder bore wear than the en-

gines with conventional finishes.

Laser-Honing: With this process,

considerably better results are

achieved compared to traditional hon-

ing. Precisely defined surface struc-

tures can be obtained with Laser tech-

nology. Laser-honing is a combination

of honing and Laser processing. This

process generates Laser-produced lu-

bricant reservoirs into a specifically

defined area in order to achieve an

ideal plateau surface finish. Such a

hydrodynamic system can be produced

exactly where it is required as shown in

Figure 18.14.

Application of the Laser-honing

process requires three steps. In the first

step – rough honing – the macro-form

www.toolingandproduction.com

Chapter 18/Tooling & Production

7

Chap. 18: Lapping and Honing

Figure 18.15. Single-stroke honing tools use

expandable diamond-plated sleeves on a ta-

pered arbor. (Courtesy Sunnen Products Co.)

Figure 18.14. Laser generated honed finished surface (Cour-

tesy: Gehring L.P.)

of the bore is produced. In the second

step, precisely defined lubricant reser-

voirs are produced with the Laser. In

step three –finish honing – an ex-

tremely fine surface finish is obtained,

resulting in increased engine life by

reduction of wear in the cylinder sur-

face and on the piston rings.

18.8 Production Honing

Honing will not only remove stock

rapidly, but it can also bring the bore to

finish diameter within tight tolerances.

This is especially true if the honing

machine is equipped with automatic

size control. With every stroke, the

workpiece is pushed against a sensing

tip that has been adjusted to the finish

diameter of the bore. When the bore is

to size, the sensing tip enters the bore

and the machine stops honing. Size

repetition from bore to bore is .0001

inch to .0002 inch. The operator sim-

ply loads and unloads the fixture and

presses a button; everything else is

automatic.

Single-Stroke Honing: A still faster

and more accurate method of honing a

bore to final size is Single-Stroke hon-

ing. The Single-Stroke tool (Fig.

18.15) is an expandable diamond

plated sleeve on a tapered arbor. The

sleeve is expanded only during set up,

and no adjustments are necessary dur-

ing honing. Unlike conventional hon-

ing, where the work-

piece is stroked back

and forth over the tool,

in Single-Stroke hon-

ing the rotating tool is

pushed through the

bore one time, bring-

ing the bore to size.

The return stroke does

nothing to the bore ex-

cept get the workpiece

off the tool. Single-

Stroke honing is so ac-

curate and consistent,

that honed bores do

not require gaging.

Although Single-

Stroke honing has

many advantages, it is

limited in the types

and volumes of material that can be

removed. The size and overall volume

of chip produced in one pass must be

no more than the space between the

diamond grits, or the tool will seize in

the bore.

Workpieces are best suited for

Single-Stroke honing when they are

made of materials that produce small

chips, such as cast iron, and that have

interruptions that allow chips to be

washed from the tool as the bore is

being honed. Conventional honing

should be used whenever the material

to be honed produces long stringy

chips, or the amount of stock to be

removed is large.

18.9 Advantages and Limitations

Honing has developed into a produc-

tive manufacturing

Process, some advantages and limi-

tations will be discussed below:

Advantages: The workpiece need

not be rotated by power, there are no

chucks, faceplates, or rotating tables

needed, so there are no chucking or

locating errors. The hone is driven

from a central shaft, so bending of the

shaft cannot cause tapered holes as it

does when boring. The result is a truly

round hole, with no taper or high or

low spots, provided that the previous

operations left enough stock so that the

hone can clean up all the irregularities.

Honing uses a large contact area at

slow speed compared with grinding or

fine boring, which use a small contact

area at high speed. Because of the

combined rotating and reciprocating

motion used, a cross hatched pattern is

created which is excellent for holding

lubrication. Diameters with 0.001 to

0.0001 inch and closer accuracies can

be repeatedly obtained in production

work.

Honing can be done on most materi-

als from aluminum or brass to hard-

ened steel. Carbides, ceramics and

glass can be honed by using diamond

stones similar to diamond wheels.

Limitations: Honing is thought of

as a slow process. However, new ma-

chines and stones have shortened hon-

ing times considerably. Horizontal

honing may create oval holes unless

the work is rotated or supported. If the

workpiece is thin, even hand pressure

may cause a slightly oval hole.