Weld using gas metal arc welding process (GMAW)

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (4.26 MB, 105 trang )

5.17A Weld using gas metal arc welding process (GMAW)

Pre-requisites:

5.50A Perform routine gas metal arc welding

18.1A Use hand tools

18.2A Use power tools/hand held operations

Reproduced with the kind permission of the Australasian Welding Journal

5.17A Weld using gas metal arc welding process (GMAW)

Range statement

GMAW undertaken autonomously or within a team

environment using predetermined standards of

quality, safety, work and welding procedures and

the skills applied to a range of fabrication activities.

A range of material suitable to heavy or light

fabrication is used.

Fillet and butt welds in all positions on a range of

materials that may include carbon steel or stainless

steel, etc.

As a guide, welds produced to the standard of this

unit would typically conform to Australian Standard

1554 General purpose, American Bureau of

Shipping (ABS) or equivalent.

Preparation of materials may include preheating,

setting up of jigs, fixtures, clamps, etc.

5.17A Weld using gas metal arc welding process (GMAW)

Range statement

Remedial action using thermal processes may

include oxyacetylene and air arc equipment.

Grinding devices may also be used.

Where thermal processes, hand and/or power

tools are required the appropriate specialisation

units should be accessed.

Element 5.17A.1 Prepare materials for gas metal arc

welding

In this element you will be required to achieve competency in the following

areas:

1.1 Weld requirements identified from specifications and/or

drawings. In this

presentation we will look at:

safety in gas metal arc welding

weld symbols.

1.2 Material is correctly prepared. In this presentation we will look at:

weld positions and weld types

methods of plate preparation.

1.3 Materials assembled/aligned to specification where required. In

presentation we will look at:

material holding devices.

this

5.17A Weld using gas metal arc welding process (GMAW)

Protective clothing

Helmet shade 10 - 13 filter lens.

Flame proof clothing (woollen or cotton):

button to collar

no cuffs or pockets

leather skull caps

leather sleeves

leather spats

safety glasses

safety boots.

Reproduced with the kind permission of BOC

5.17A Weld using gas metal arc welding process (GMAW)

Hazards in welding

All welding is hazardous to your own safety and others.

Electric shock (low voltage, secondary side):

caused by:

wet floors and weather.

Electric shock (high voltage, primary side):

250 - 415 volts

caused by:

tampering with mains power lead

interfering with internal parts.

Remedy

maintain machine by licensed electricians.

5.17A Weld using gas metal arc welding process (GMAW)

General rules

Wear dry insulated boots.

Wear dry gloves.

Work on dry floors.

Don’t change electrodes with bare hands.

Don’t cool electrode holders in water.

Don’t hold electrode under arms.

Don’t form a circuit.

In case of electrocution turn off power. If unable

remove victim with non-conducting materials

eg: welding leads, wood, dry clothing.

5.17A Weld using gas metal arc welding process (GMAW)

Fumes

Are harmful if breathed in:

causes:

production of oxides and nitrous gases (incomplete

combustion or oxidisation of nitrogen from

atmosphere).

Caused by:

surface coatings:

galvanised coatings

cadmium coatings

chrome coatings

paint and solvents

composition of parent metal

electrode fluxes.

Reproduced with the kind permission of the

Australasian Welding Journal

5.17A Weld using gas metal arc welding process (GMAW)

Dangerous fumes

Dust and vapours are given off in welding

processes, eg: lead, cadmium, zinc.

They cause:

gassing or asphyxiation because

oxygen has been depleted

respiratory ailments from wheeziness

and serious lung disorders.

Always use ventilation where possible,

otherwise use respirators.

5.17A Weld using gas metal arc welding process (GMAW)

Heat

Welding produces great amounts of heat:

arc heat = 60000C.

Types

Conduction:

travels through a solid:

Reproduced with the kind

copper and AL are good conductors

permission of Strata Group

International

cast iron and SS are poor conductors they localise heat.

Radiation:

travels through air by wave motion:

no physical contact necessary

during intensive welding such as pad welding.

5.17A Weld using gas metal arc welding process (GMAW)

Harmful rays

Rays given off during the welding process are:

Ultra-violet - causes:

flashes:

takes 4 - 8 hrs to develop

fills like sand in eyes

rays very deep penetrating.

Infra-red:

like sun burn

can cause blisters and sores.

Reproduced with the kind permission of the Australasian Welding Journal

Protect yourself from these by wearing the correct

equipment and lens filters shade 10 minimum.

5.17A Weld using gas metal arc welding process (GMAW)

Hazardous locations

A hazardous location is an area where flammable or explosive substance are

present or have been.

No oxygen equipment can be taken into these areas unless a permit is

obtained from a safety officer.

HAZARDOUS LOCATIONS

Alcohol distilleries, oil refineries, paint factories, explosive plants, coal

crushers, flour mills, saw mills, wheat silos, paper mills.

PROCEDURE FOR HAZARDOUS LOCATIONS

Inform safety officer of work and equipment to be used.

Officer must inspect site and make safety recommendations.

Safety officer must issue a work permit.

When cutting, welding or heating you must know the location of the

nearest fire brigade and telephone number.

Have on hand the correct fire extinguishers.

Wait 1 hour minimum after you have finished cutting, welding or heating.

5.17A Weld using gas metal arc welding process (GMAW)

Confined working areas

Confined working areas are where ventilation or accesses are

restricted.

CONFINED LOCATIONS INCLUDE:

Tanks, containers, bins, silos, ship hulls, ducts, chutes, pipelines.

PROCEDURES FOR CONFINED SPACES

Check with supervisor or safety officer before beginning work.

Ventilate by forced draught (fans).

Assistant outside at all times.

Rescue apparatus outside at all times.

Light blowpipes outside confined spaces.

Use 32 volt lighting and hand tools.

Be aware of oxygen enriched atmospheres.

Be aware of sealed containers (oxygen depleted).

5.17A Weld using gas metal arc welding process (GMAW)

Dangerous containers

Containers which hold or have held flammables.

Flammables can get into seams.

Don’t rely on sight or smell.

Obtain a chemical analysis.

Obtain a work permit from a safety officer.

CLEANING AND PURGING PROCEDURES

Steam clean containers for 30 minutes minimum after

container is hot.

Fill container with water and bring to a boil. Boil for 30

minutes minimum (remove all caps).

Fill container with water or an inert gas just below weld site

and vent to atmosphere.

Obtain approval from a safety officer before working on

containers after all of the above.

5.17A Weld using gas metal arc welding process (GMAW)

Welding symbols

The symbol consists of an arrowhead and leader joined to a

reference line. On one or both sides are placed the symbols

with figures that refer to the type of weld and its size.

A tail may be added for reference notes.

Basic symbols are used to depict the:

preparation

weld type

size of the weld

weld finish.

Reproduced with the kind permission of Standards Australia

5.17A Weld using gas metal arc welding process (GMAW)

Example - Welding symbol

Basic weld symbol.

10mm fillet weld other side.

6mm fillet weld arrow side.

10

GMAW

6

Weld on site.

Weld all round.

Use the gas metal arc welding process.

5.17A Weld using gas metal arc welding process (GMAW)

Meaning of common symbols

8mm fillet weld arrow side of joint.

12mm fillet weld both sides of joint.

Single vee butt weld arrow side of

joint.

Single vee butt weld arrow side of

joint:

flush deposit.

Reproduced with the kind permission of Standards Australia

5.17A Weld using gas metal arc welding process (GMAW)

Meaning of common symbols

12mm fillet weld arrow side of joint:

bevel preparation arrow side of joint.

backing bar other side of joint.

Bevel preparation arrow side of joint:

flush deposit.

Reproduced with the kind permission of Standards Australia

5.17A Weld using gas metal arc welding process (GMAW)

Meaning of common symbols

Stitch weld arrow side of joint:

weld 50mm

miss 100mm.

Stitch weld both side of joint:

weld 50mm

miss 125mm.

Staggered stitch weld:

weld 75mm both sides

miss 250mm both sides

125mm between welds centres

either side of joint.

Reproduced with the kind permission of Standards Australia

5.17A Weld using gas metal arc welding process (GMAW)

Weld positions

All welding takes place in what is determined as 4 major

welding positions.

These welding positions can be out of alignment by + or - 150.

OVERHEAD

VERTICAL

HORIZONTAL

FLAT

OR

DOWN HAND

5.17A Weld using gas metal arc welding process (GMAW)

Weld positions

Reproduced with the kind permission of BOC

5.17A Weld using gas metal arc welding process (GMAW)

Weld types

Reproduced with the kind permission of BOC

5.17A Weld using gas metal arc welding process (GMAW)

Fillet weld terms

Parent Metal

Leg Length

Reinforcement

Weld Metal

Toe

Fusion Zone

Penetration

Heat Effected Zone

5.17A Weld using gas metal arc welding process (GMAW)

Butt weld terms

BUTT WELD TERMS

INCLUDED

ANGLE 60o 70o

ROOT GAP

REINFORCEMENT

ROOT FACE

PARENT

WELD

METAL

THROAT

METAL

FUSION ZONE

HEAT EFFECTED ZONE

PENETRATION

5.17A Weld using gas metal arc welding process (GMAW)

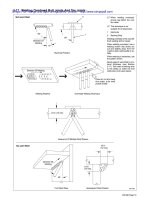

Butt weld preparations

Closed butt:

no preparation required

suitable for up to 3mm plate.

3

1.5 to 2.5

Open butt:

5

no preparation required

suitable for plate from 3mm up to 6mm.

Single vee:

plate up to 12mm.

1.5 max

1.5