Drilling and Associated Cutting Tool Technology Industrial Handbook_1 pdf

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (615.67 KB, 9 trang )

3

Drilling and Associated

Technologies

‘In all things, success depends upon previous preparation

and without such preparation……there is sure to be failure.’

(c550–c487BC)

[Analects]

3.1 Drilling Technology

.. Introduction to the Twist

Drill’s Development

Drilling operations are perhaps the most popular ma-

chining process being undertaken today, with their

origins being traced back to cutting tool develop-

ments in North America in the 19

th

century. In 1864

toward the latter part of the American Civil War, Ste-

ven Morse (i.e. later to design the signicant ‘Morse

taper’ – for accurate location of the ‘sleeved drills’

into their mating machine tool spindles) founded

the Morse Twist Drill and Machine Company in the

‘North’. Morse then proceeded to develop probably the

most important cutting tool advance to date, namely,

the ubiquitous twist drill. In Fig. 42, several of today’s

twist drills are illustrated along with just a small range

of ‘solid’ contemporary designs. Morse’s originally-de-

signed twist drill has changed very little over the last

150 years – since its conception. In comparison to the

somewhat cruder-designed contemporary drills of that

time, Morse stated: ‘e common drill scrapes metal to

be drilled, while mine cuts the metal and discharges the

chips and borings without clogging’. Morse’s statement

was at best, to some extent optimistic, whereas the

‘cold reality’ tells a dierent story, as a drill’s perfor-

mance is inuenced by a considerable number of fac-

tors, most of which are listed in Fig. 43.

.. Twist Drill Fundamentals

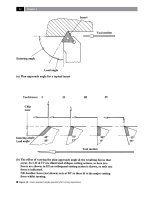

e basic construction of a conventional twist drill is

depicted in Fig. 44a. From this illustration two dis-

tinct cutting regions can be established: rstly, the

main cutting edge, or lips; secondly at the intersection

of the clearance and main cutting edge – termed the

chisel edge. In fact for a twist drill, the cutting process

can be equated to that of a le-hand oblique turning

tool, where the rake and clearance face geometries are

identical and the correlation between these two ma-

chining processes have been validated in the experi-

mental work by Witte in 1982. Both of these regions

remove material, with the cutting lips producing ef-

cient material removal, while the chisel edge’s con-

tribution is both inecient and is mainly responsible

for geometric errors in drilling, coupled to high thrust

loads.

e main cutting edges are accountable for a rela-

tively conventional chip formation, as shown in the

‘quick-stop’ photomicrograph in Fig. 44b. An oblique

cutting action occurs to the direction of motion, being

the result of an oset of the lips that are parallel to a

radial line – ahead of centre – which is approximately

equal to half the drill point’s web thickness and in-

creases toward the centre of the drill. is obliquity is

responsible for inducing chip ow in a direction nor-

mal to the lips in accordance with Stabler’s Law

1

. e

increasing chip ow obliquity can be seen in Fig. 45a,

by observing the ow lines emanating from the chip’s

interface along the lips and up the ute face. Such

an oblique cutting action serves to increase the twist

drill’s eective rake angle geometry. With the advent

of ‘Spherical trigonometric computer soware’ for ob-

taining direct three-dimensional calculations – previ-

ously described by Witte (1982) in two-dimensional

formulae for cutting edge performance – these calcu-

lations have been enhanced.

Under the chisel point, or web, the material re-

moval mechanism is quite complex. Near the bottom

of the utes where the radii intersect with the chisel

edge, the drill’s clearance surfaces form a cutting rake

surface that is highly negative in nature. As the centre

of the drill is approached, the drill’s action resembles

that of a ‘blunt wedge-shaped indentor’ , as illustrated

in Fig. 45b. An indication of the inecient material

removal process is evident by the severe workpiece

deformation occurring under the chisel point, where

such deformed products must be ejected by the drill to

produce the hole. ese ‘products’ are extruded, then

wiped into the drill ute whereupon they intermingle

with the main cutting edge chips. is fact has been

substantiated by force and energy analysis, based on a

combination of cutting and extruding behaviour under

the chisel point, where agreement has been conrmed

with experimental torque and thrust measurements.

e chisel edge in a conventionally ground twist drill

has no ‘true’ point, which is one of the major sources

for a drilled hole’s dimensional inaccuracy.

1 Stabler’s Law – for oblique cutting, can be formulated, as be-

low:

Chip ow (cos η) = cos I (b

c

/b)

Where: I = inclination of cutting edge, b

c

= chip ow vector,

b = direction of cutting vector.

Chapter

e conventional twist drill chisel point geometry

can be seen in Fig. 46, together with associated no-

menclature for critical features and tolerance bound-

aries. From the relatively complex geometry and

dimensional characteristics shown in Fig. 46, the ob-

tainable accuracy of holes generated whilst drilling is

dependent upon grinding the drill to certain limits.

Any variations in geometry and dimensions, such as:

dissimilar lips and angles, chisel point not centralised,

and so on, have a profound eect on both the hole di-

Figure 42. A selection of just some of the many ‘solid’ and ‘through-spindle’ drilling varieties and ‘inserted-edge’

insert geometries currently available. [Courtesy of Seco Tools]

.

Drilling and Associated Technologies

Figure 43. The principal technical drill performance criteria and factors associated with drilling operations in this case for ex-

ample, on castings

.

Chapter

Figure 44. The twist drill geometry and associated chip shearing mechanism. [Source: C.J. Oxford Jr., 1955].

Drilling and Associated Technologies

Figure 45. The twist drill shearing and extrusion mechanism at the bottom of a hole. [Source:

C.J. Oxford Jr., 1955]

.

Chapter

Figure 46. Twist drill geometry.

Drilling and Associated Technologies

mensional accuracy and roundness, with some ‘helical

wandering’

2

as the drill passes through the workpiece.

Hole accuracy and in particular the ‘bell-mouthing ef-

fect’

3

, is minimised by previously centre-drilling prior

to drilling to ‘size’. e main cause of such this ‘bell-

mouthing’ is probably the inconsistency in the drill

geometry. Such eects are exacerbated using Jobber

drills

4

, or even worse, by utilising longer-series drills,

which tend to either slightly ‘unwind’ , or bend as a re-

sult of lessening rigidity promoting some drill bend-

ing/deection.

It is worth noting that the rigidity of a tool such

as a drill will decrease by the ‘square of the distance’

5

.

erefore it follows that the greater the drill penetra-

tion into the workpiece, the progressively larger the

deection and, the further from the ‘true axis of rota-

tion’ will be the subsequent drill’s path. is deected

drilled hole slope angle ‘ϕ’ , can be dened in the fol-

lowing manner:

Drilled hole slope angle

‘φ’ = 3/2 l × R/T (1 – I/k × tan k l)

Where:

l = length of deected tool,

2 ‘Helical wandering’ is the result of the drill’s geometry be-

ing ‘unbalanced’ , resulting from of diering lip lengths, or an

oset chisel point, causing the drill to ‘spiral-down’ through

the workpiece, as it progresses through the part (see Fig. 70).

‘Bell-mouthing’ of the drilled hole is attributable to the chisel

point and is produced by the line-of-contact, as the drill point

initially touches the component’s surface, causing it to ‘walk’

until the feed/penetration stabilises itself at the outer corners

(i.e. margins) entering the workpiece, whereupon, these mar-

gins guide the drill into the part.

3 ‘Bell-mouthing eect’ is produced by the drill chisel point’s

eccentric behaviour as it attempts to centralise its rotational

motion as it enters, or exit’s the workpiece.

4 ‘Jobber drills’ are considered to be ‘standardised drills’ that

are normally utilised for most drilling general operations, un-

less otherwise specied.

5 ‘Rigidity rule’: a drill, reamer, tap, or a milling cutter held in

a spindle will have its rigidity decreased by the ‘square of the

distance’ , namely, if a drill is twice as long it is four times less

rigid.

NB A cantilevered tool such as a boring bar has its rigidity de-

creased by the ‘cube’ or the distance – meaning that too much

tool overhang, will seriously reduce tooling rigidity.

R = ratio of the transverse reaction at the drill point,

T = thrust force,

I = system’s ‘moment of inertia’ ,

k = √T/E I.

As suggested above, this ‘axis slope error’ is initiated

when the chisel edge begins to penetrate the workpiece

and unless the feed is discontinued, or in some man-

ner the error is corrected, the magnitude of deection

will increase as drill penetration continues. e drill’s

magnitude of deection can reach up to 60 µm, under

exaggerated drilling conditions.

e geometry of the point has been the subject

of considerable research and development for many

years, with some unusual departures from the ‘stan-

dard’ 118° drill point included angle. Typical of these

extreme approaches were the so-called ‘Volvo point’ ,

having a negative 185° included angle – primarily

utilised to avoid ‘frittering’

6

of drilled holes, or the

highly positive geometries such as 80° included an-

gle used for drilling some plastics. Not only can the

point angle be modied, but the shape and prole of

the chisel point, or web

7

oers numerously-ground

opportunities for detailed geometric modications,

with only some of which being shown in Fig. 47. Four

of the most commonly-ground drill point geometries

being:

•

Conventional – the ‘original’ Morse geometry, hav-

ing a straight chisel edge, with poor self-centring

drilling action (Fig. 46a),

•

Split-point

8

– there are a range of point-splitting

techniques available to alter the point prole, which

has the eect of modifying the chisel point to allow

a reasonable self-centring action (Fig. 47b),

6 ‘Frittering’ refers to the break-out at the hole’s edge as the drill

exit’s the part, on some brittle materials, such as on several

Powder Metallurgy compacts.

7 ‘Web’ refers to the internal core of the drill – which imparts

mechanical strength to the drill. e web increases in thick-

ness the further one gets from the chisel edge (i.e. shown in

Fig. 47 – in lower diagrams and with cross-sections). Hence,

if the drill is reground many times, the chisel point width will

obviously increase, this necessitates that the chisel point must

be ‘thinned’ , otherwise too high a thrust force occurs and an

inecient drilling action will result.

8 ‘Split-point’ ground drills are sometimes referred to as ‘Multi-

facet drills’.

Chapter

Figure 47. A range of typically ground twist drill points.

Drilling and Associated Technologies