An Encyclopedia of the History of Technology part 4 pps

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (102.24 KB, 10 trang )

INTRODUCTION

12

sharpened flints set into the blade with bitumen. At an oasis near the Dead

Sea, as at other places, a village grew into a city: this was Jericho, with fortified

walls and buildings, at first of reed and mud, then of unbaked clay until baked

brick was used between 8000 and 6000 BC. Barley and millet were also grown

and harvested (see Chapter 16). As well as the already domesticated dog, the

sheep, the goat and the onager, a form of ass, were added to the domestic

animals. Pottery was made not only by the old method of smoothing together

coils of clay but also on the newly invented potter’s wheel. Copper was used

for ornaments in Egypt about 4000 BC (see Chapter 1). It came 1nto more

general use for making tools 1000 years later, at about the time that tin, which

could be alloyed with it to make bronze, was discovered in Mesopotamia. Iron

was not discovered as a useful material until about 1500 BC (see Chapter 2).

Social influences of copper and iron

The social implications of copper and iron were very different. Copper, as later

bronze, was something of a rarity and consequently expensive when it had been

worked into a tool or weapon by someone with the skill and knowledge to do so.

It came, too, at a time before there was an establishment, a hierarchy of king and

priest and counsellor. Wealth was the only uncommon denominator and wealth

could be equated with worldly success in the business that mattered most—

success in agriculture. Copper tools, and weapons, thus became available only to

the powerful, to those who were already wealthy, and had the effect of increasing

their power and multiplying their wealth. It thus tended to create an elitist society

in which the majority, who formed the lower ranks, were still confined to

grubbing the earth with tools of bone and wood and stone. It was socially

divisive, helping only the rich to become richer in creating the small agricultural

surpluses that were to be at the foundation of subsequent cultures.

The technology of ironmaking and the forging of tools and weapons from the

refined metal was a more complex process, a more specialized business. On the

other hand, iron became more widely available than copper or bronze, it was far

cheaper and could be made into much better and longer lasting tools and

weapons. Thus, once the techniques and the craftsmen became established, iron

tools became more generally available to a wider spectrum of the population

than had those of copper or bronze. Iron has rightly been called the democratic

metal, the metal of the people, for so it was in comparison with its predecessor.

The common ground

On the other hand, the introduction of metallurgy, whether of bronze or

iron, and its processes did become the start of a new way of living in which

BASIC TOOLS, DEVICES AND MECHANISMS

13

specialization and the division of labour were important factors. Metal

workers were a class of specialists who needed specialist equipment and who

depended for their sustenance on the labours of their fellow men, the

farming community for whom they provided the tools. Many ancillary

trades, too, were involved, in the quarrying or mining of the ores to be

smelted. The construction of furnaces and the manufacture of crucibles were

to become other objects of specialization. The human lungs and the blowpipe

produced a very limited area of high temperature for smelting, so that the

blowpipe was virtually restricted to goldsmiths. Around 3000 BC bellows

were developed, at first from the whole skins of sheep, goats or pigs, or from

clay or wooden pots topped with a flexible membrane of leather. Copper ore

was not to be found in sufficient quantity in the ‘fertile crescent’ where it was

first used. Thus traders and carriers were required using, at first, pack

animals and later wheeled vehicles, then riverboats and sea-going ships. All

these called for further specialists to produce them. These in turn needed

further tools with which to work and added to the number of specialists who

had to be fed.

It has been suggested that copper ore was mined at Mount Sinai as early as

5000 BC and 2000 years later in Oman in the south of Arabia. These are

respectively some 1400 and 2000km (875–1250 miles) from Mesopotamia, a

long haul for the unrefined ore and a powerful incentive towards the invention

of the wheel. It was about 3500 BC that the wheel was first added to a

primitive sledge at Erech in Sumeria. Strictly speaking, the invention consisted

more of the axle to which the wheel was fixed, for previously wheel-like rollers

had been placed beneath the sledges, especially when heavy loads were

involved.

Some of the heaviest of these were the great obelisks, a characteristic of

Egyptian civilization, which were as much as 500 tonnes in weight and 37m

(122ft) h1gh when erected. They were quarried in the horizontal position, in

one piece, from around 1470 BC. It is believed that the huge blocks were cut

out of the parent granite by continual pounding from a round stone of dolerite

so as to generate a narrow trench all round; the final undercutting to separate

the obelisk must have been an awesome task. Apart from the glory brought to

the name of the pharaoh who had ordered the obelisk, it had little use except

as the gnomen of a sundial.

The plough was a vital invention for a civilization that was becoming

increasingly dependent on agriculture, and a great improvement on the hoe as

an instrument for tilling (see Figure 3). An intermediate device, which survived

in the Hebrides until the nineteenth century as the caschrom, was the

lightweight man-plough and it was not until about 3000 BC that animals

started to be harnessed to the plough or the cart. In warfare, horses were at

first used to draw two-wheeled chariots: men did not learn to ride horses until

about 2000 BC and the saddle is a much later invention which did not become

INTRODUCTION

14

truly effective until stirrups were added, allowing the horseman a better

purchase with sword or spear.

There has always been a need to join one piece of material to another, be it

wood, leather or metal, or to join wood to stone as in the hafted axe. Thongs

and cords or ropes of fibres woven together served at first, but both the nail

and the rivet were known to the coppersmiths of Egypt well before 2500 BC.

Such nails were used in sailing ships some five centuries before that date.

These again were Egyptian and represent the first known application of a

natural source of power other than animal power, the wind. The use of wind

power to drive the rotating sails of a windmill does not appear to have

occurred for another three millennia or more.

The Iron Age naturally brought with it, among other things, iron nails,

but for large timbers, such as are used in ships, where these were to be

joined, it was common to use trenails. These were no more than closely

fitting dowels and they remained the conventional method of joining ships’

and other heavy timbers until iron replaced wood as the basic construction

material in the nineteenth century AD. There is some doubt about the

woodscrew: examples exist from Roman sites between AD 400 and 450, but

in a very corroded state so that it is impossible to be sure of their purpose.

All that we know for sure is that the first illustration of a woodscrew is in

Agricola’s De Re Metallica, first published in Venice in 1566. This remarkable

and detailed work does not mention that there was anything unusual about

the woodscrew, from which it has been assumed that by that time it was an

article generally in common use.

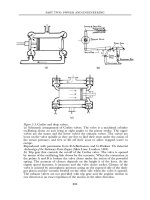

Figure 3: The plough. The development of more effective instruments for tilling

the soil lies at the heart of agricultural production. An Egyptian hand digging

implement, c. 1500 BC. See Chapter 16.

BASIC TOOLS, DEVICES AND MECHANISMS

15

Another method of joining wood, known at least by 3000 BC, was the

mortise and tenon joint, implying the use by that date of quite sophisticated

carpenter’s tools. These must have included saws and chisels and a high

degree of skill must have been needed to use them effectively.

The first type of hinged tool, as we know it today, with two separate

components, was in fact made in one piece, depending on the spring of one

part of the metal for the relative movement between the two blades. The

Egyptians, perhaps as early as 4500 BC, had shears similar to a tailor’s

scissors (and they are still made in steel in Japan). With these they could

cut silhouettes, and it is suggested that this resulted in the Egyptian

convention of making carved or painted representations in profile. The

same principle was then applied to making tongs for those employed in

coppersmith’s work. Previously there was no alternative to holding the hot

metal between two stones.

It may appear to the reader that an excessive number of events and inventions

are recorded as having taken place in the period 3500–3000 BC. There may be

some unintentional distortion of the facts due possibly to the dating of the

earliest surviving written records. The first known writing was the cuneiform or

wedge-shaped script evolved by the Sumerians about 3400 BC. Before that

everything depended on memory and speech, the only method of recording and

recalling the past. Egyptian hieroglyphic writing followed within a couple of

centuries and by 2000 BC the Egyptians had reduced their system to an

alphabet of twenty-four letters. In contrast, the Chinese, in advance in so many

other techniques, were not so in writing. It is known that Chinese writing was

well established by 1700 BC, but the date of its origin is not known.

Pots and baskets

The development of both tools and weapons increased the demand for

containers in which to remove the spoil of excavation or to preserve or to cook

the winnings of the hunt. Basketwork is a characteristic of the Neolithic Age and

is a development of the weaving of rushes to make floor coverings for mud huts.

Such forerunners of the carpet date from some time before 5000 BC. The same

weavers learned to work in three dimensions so as to produce baskets in which

grain could be stored. By 3000 BC the skill was widespread.

Similarly pottery, in its broadest sense, did not start with the making of pots

(see Chapter 3). Long before vessels were made—as early it seems as 25,000

BC—small figures representing human beings were moulded in clay and baked,

at first, in the sun. The making of pots by coiling strips of clay in a spiral and

then moulding them together is supposed to date from about 7000 BC, as is

the moulding of clay to take the form of the inside of a basket. Sun drying

would be insufficient to produce a watertight vessel and slow baking in a kiln

INTRODUCTION

16

would be required. The kiln process was first used in Mesopotamia and Persia

around 4000 BC and in Egypt within the next thousand years.

The advance of the wheel

The inventor of the potter’s wheel wrought, perhaps, better than he knew. A

simple turntable mounted on a central pivot was turned by an assistant so that

the potter had both hands free with which to manipulate the clay. It originated

about 3500 BC in Mesopotamia, not far from Sumeria where, at about the

same time at Erech, came that great advance in technology, the addition of an

axle to a sledge on to which a wheel could be fixed, thus to form a primitive

cart or wagon. Both of these concepts were, of course, preceded by the use of a

round flat stone with a hole in the centre to act as a flywheel when spinning

thread for weaving. Doubtless the wagon at Erech was an experiment and

doubtless the same idea came to others about the same time: technology has a

habit of working like that. But to the anonymous experimenter at Erech must

go our thanks, for what would we do without wheels and axles today?

Glass

Until the plastics age of the twentieth century, and many might say into and beyond

it, glass was the ultimate material for making containers. It resists all substances—

except hydrofluoric acid. It exists in nature in the form of obsidian, a volcanic rock of

which man-made artefacts have been found, such as arrowheads. The earliest man-

made glass is dated at about 4000 BC in Egypt, as a simple glaze on beads. Not until

about the seventh century BC are Assyrian examples of small decorated jugs found,

made by casting the glass round a clay core which could then be scraped out. A great

advance was the blowing iron, allowing larger and thinner vessels to be made. This

originated in the first century under the Romans.

Gearing

We know little more of when and where gear wheels originated than we do of

the invention of the wheel. Aristotle (c. 384 BC) recorded seeing a train of

friction wheels set in motion, that is a series of contiguous wheels with smooth

peripheries but without teeth. Ctesibius of Alexandria is said, by Vitruvius, to

have constructed a water-clock with gears about 150 BC. In this, a primitive

rack was mounted on a floating drum and meshed with a circular drum so as

to rotate it. This is the earliest reference to toothed gearing, but no mention is

made of the materials used.

BASIC TOOLS, DEVICES AND MECHANISMS

17

Gearing, then, developed in two materials—in wood for large installations

transmitting power; and in metal, usually bronze or brass initially, for

timekeeping and other related astronomical instruments. The earliest surviving

‘mathematical gearing’, as the latter is known, is probably the Antikythera

mechanism now in the National Archaeological Museum, Athens, which takes

its name from that of a Greek island off which it was found in a wreck in AD

1900 and is thought to date from the first century BC. It is supposed, from the

complexity of this mechanism, of which no less than thirty-one gear wheels

survive, that this was far from the first example to be made and that, by that

date, there was an established tradition of making mathematical gearing. The

teeth on such an early example of gears were filed with a straight tooth profile

and a root angle of approximately 90 degrees.

Wooden power transmission gears for mills date at least as far back as

Roman times, a comprehensive range of carpenter’s tools being available such

as lathe, plane, bow drill, saw, chisel, awl, gimlet and rasp. It was customary at

that time to bind the ends of shafts with iron hoops as well as to line the pivot

sockets of timbers to provide a bearing surface. The blacksmith was equipped

with forge hearth, bellows, hammer, tongs and anvil by the time of Vitruvius,

who wrote about these matters in about 25 BC.

The traditions established at this time in both carpentry and blacksmithing

were to continue well into the nineteenth century with little change in

techniques but with great improvements in the products made. Improved tooth

profiles, so as to provide true rolling contact between gears, were introduced.

Bevel gears were substituted for the earlier ‘lanthorn and trundle’, the latter

being a wheel with pegs, and later shaped teeth, set into its flat surface, the

lanthorn resembling a lantern or bamboo birdcage, two discs being connected

by a number of pins or dowels equally spaced near to their periphery. The use

of wrought iron in clock gears from the Middle Ages developed into the use of

cast-iron mill gearing in the 1770s, but mortise gears—wooden teeth let into a

cast-iron rim—persisted into the nineteenth century. Hornbeam was the most

popular wood until lignum vitae, the wood of the guaiacum tree, a native of

South America, began to be imported in the eighteenth century.

Helical gears were developed by Robert Hooke in 1666. There being then

no machinery for cutting such teeth, he built them up from a series of

laminations which were staggered or progressively displaced when the faces of

the teeth were then filed smooth. Ten years later Hooke devised the universal

joint named after him and contributed much to later mechanical engineering.

Early machines in Egypt

It was not until about the time of Christ that Hero of Alexandria classified the

five basic machines as the lever, the wheel and axle, the wedge, the pulley and

INTRODUCTION

18

the screw, but the first three of these had been in common use since about

3000 BC. The shaduf for irrigation and the balance beam for weighing were

applications of the lever. It was, as we have already said, at about this time that

written records started with the Sumerian invention of cuneiform script usually

inscribed on clay tablets. The same period saw the first attempts at

standardization of weights and of linear measures, the span, the palm, the pace,

the inch and the cubit all being based on parts of the human body by the

Egyptians.

The Egyptians were also the first large-scale builders, largely using huge

quantities of slave labour rather than mechanization, or craftsmen working off

their tax dues or debts. No pulleys, for instance, were used in raising the

thousands of huge blocks of limestone for the pyramids. The great pyramid of

Cheops covered over 5.3 hectares (13 acres) and contained some 2.3 million

blocks of over 1 tonne each. It was 146m (479ft) high. Though it was a natural

progression for a civilization that had the wheel, the Egyptians did not have

the pulley. The first depiction of it is in an Assyrian relief dating from the

eighth century BC, in which it is clearly shown in use on a building site

hauling up a bucket or basket, the workman on the ground grasping a pointed

mason’s trowel.

In spite of the replacement of the blowpipe by bellows, at first operated by

hand but later by the feet, articles of iron were of limited size even towards

the end of the Egyptian Empire, that is, until about 600 BC. Drill bits,

chisels, rasps, door hinges, edging for ploughshares, bearings, spindles and

hoes are typical. Wood and stone were the principal materials of the

Egyptians. Cast iron, however, was developed by the Chinese as early as the

fourth century BC.

Greece and Rome

The Greeks were great builders but, apart from a few exceptions such as

Archimedes, were theoretical scientists rather than practical technologists.

Their contributions to sciences such as mathematics and astronomy, were

considerable—not to mention philosophy—but they were not great inventors

except, perhaps, in the production of mechanical devices to strike the

worshipping plebeians in the temples with a sense of awe. Falling weights drove

some of these, but more common was the use of hot air or hot water, even

steam being brought into service as well as a form of windmill. The Romans,

although a far more practical people, invented little of their own but did much

to adapt the principles, used by the Greeks only for their temple ‘toys’, to large-

scale practical applications such as could be used ‘for the public good’.

The Greek and Roman empires lasted for about a thousand years, from 600

BC to about AD 400, during which period the Chinese made some remarkable

BASIC TOOLS, DEVICES AND MECHANISMS

19

advances in technology. They had cast iron as early as 350 BC, some thirteen

centuries before it was known in the West; they developed the double-acting box

bellows; steel was produced in the second century BC; they invented

papermaking about AD 100. Gunpowder, mainly used in fireworks, is another

Chinese invention. It is surprising that there seems to have been so little transfer

of technology to the West in spite of so many travellers passing along the ‘Silk

Road’. These, however, were merchants or royal or papal envoys. Technology

was, perhaps, above the intellectual level of the merchants and below the notice

of the envoys. Marco Polo, for instance, in his Travels, recorded by Rustichello of

Pisa in 1298–9, records the glories of architecture, customs, weapons and

armour, food, gemstones, crops, natural history, governments and rulers but

rarely, if ever, records seeing a technological process in twenty years of

wanderings in the Middle East, India and China.

One practical invention of the Greeks was the horizontal waterwheel, the

predecessor of the turbine, now known more commonly as the Norse mill.

This was the first form of power of non-animal origin except, perhaps, the

sailing ships used by the Egyptians as early as 2500 BC. Its use spread

northwards throughout Europe. Except for the shaft from the wheel to the

millstones above and the bearings, which were usually of iron, practically the

whole construction was of wood which became the principal material of

millwrights for the next thousand years.

The Roman mill, described by Vitruvius in about AD 180, was the first

machine in which gears were used to transmit power. This mill had a vertical

wheel driving the horizontal upper millstone through lanthorn and trundle gears.

However, the Romans were well supplied with slaves and hence not encouraged

to invest in labour-saving mechanization. Watermills did not increase greatly in

number until the fourth and fifth centuries AD, towards the end of the era of the

Roman Empire. By the time of the Domesday Book, completed in AD 1086, this

survey was to record over 5600 in use in England alone, mostly used for corn

milling but possibly a few for ore crushing and for driving forge hammers.

In building, the Romans used cranes frequently fitted with a treadmill to

turn the windlass, the rope running in pulleys. The most powerful of them

were of about 6 tonnes’ lifting capacity. The stone blocks were lifted by means

of a ‘lewis’, a dovetail cut by a mason in the upper surface into which a

wedgeshaped metal anchor was fitted and locked in place by a parallel-sided

metal key. The key of the lewis and the wedged anchor could be released

when the stone had been positioned, even under water.

As well as the extensive network of roads across the Roman Empire, which

included many bridges, a great number of aqueducts were built to supply

water to their cities. The construction of river bridges often involved the

building of coffer dams of timber piles, sealed with clay, and in the building of

these two machines were used: first, the pile driver and, second, the ‘snail’ or

Archimedean screw to drain the water from the completed coffer dam.

INTRODUCTION

20

Water supply was of the greatest importance, for the Romans in the cities

are said to have used more than 270 litres (59 UK gallons, 71 US gallons) per

person per day. Rome in the fourth century AD had over 1350 fountains and

850 public baths, while flowing water was also used for flushing the plentiful

sewers. Some houses at Pompeii had as many as thirty water taps each. The

common use of lead pipes for water distribution, producing lead poisoning and

resulting in brain damage, is held by some to have been one of the causes of

the decline of the Roman Empire.

The Dark Ages

The last Roman troops left Britain in AD 436 and all contact between Britain

and Rome had ended by 450. To a great extent the Roman legacy of roads,

bridges and aqueducts died, the relics being allowed to fall into disuse and

decay, but a good deal of knowledge was preserved as well as the skills to

transmute it into practice. Many of the engineering crafts were kept alive by

the monastic orders who became rich on the basis of the products that they

made but largely from the water-powered mills that they built and operated.

The Romans, for instance, had superseded the half horsepower (or one

donkey power) Greek or Norse mill with the Vitruvian mill which generated up

to three horsepower. As civilization could no longer depend on large numbers of

slaves, there was a demand for such mechanization as was available and the

successors of the Romans continued to build water mills. At the time of the

Domesday survey there was an estimated population in England, south of the

Severn to the Trent, of nearly 1 1/2 million and hence one watermill for every

250 people, the vast majority being devoted to corn milling. Later, from AD

1000 on, mills were used for beer-making and for fulling cloth, particularly

woollen fabrics. Later applications were for forge hammers and bellows, for

paper-making, crushing woad and bark for tanning, for grinding pigments and

also for making cutlery, for water lifting and irrigation, and for saw mills, lathe

drives and wire-drawing. In the twelfth century engineers turned their attention

to harnessing wind power and the first post mills resulted. Tidal mills also

existed, but had the disadvantage that their working hours varied each day. The

first mention of a post mill is in about 1180 in Normandy. Post mills were of

necessarily limited size and hence powder, but tower mills, which first appeared

in the fourteenth century, could double or treble this. They did not come into

extensive use until the sixteenth century, particularly then in the Netherlands.

Naturally most inventions of the period were related to agricultural

improvements, textile production or building construction, or else for military

applications. Agricultural performance was greatly improved with the

development of the horse collar which transferred the load from the neck of

the horse to the shoulders, thus not interfering with its breathing. Though

BASIC TOOLS, DEVICES AND MECHANISMS

21

more costly in food, needing oats, the horse continued to replace the ox and

nailed iron shoes took the place of the earlier cord or leather sandals with

which horses had been shod. The heavy wheeled plough and the harrow also

appeared and helped to increase production. The three-field system of crop

production was introduced. In the military arena, stirrups improved the

purchase of a horseman allowing him to transfer the momentum of his mount

to the weapon in his hand, be it sword, axe or lance.

Some idea of the state of manufactures in the sixth and seventh centuries is

given by artefacts found in the excavation of the Sutton Hoo ship in 1939 near

the River Deben, not far from Ipswich in Suffolk. There an impression of a

ship, its timbers decayed and disintegrated, was found in one of seventeen

mounds, many still unopened, although there were signs that others had been

disturbed in the sixteenth century. It was, if not a royal burial place, a royal

memorial; no body was found, although there were signs of a coffin. A helmet,

a sword of gold with garnet fittings, a battle axe, a spear, silver and bronze

bowls, a gold buckle or reliquary, intricately worked and patterned, a purse of

Merovingian coins, silver-mounted drinking horns, spoons and jewellery were

among the buried treasure.

The ship itself had been carvel-built of 2.8cm (1 in) planks for sailing or

rowing by thirty-six men. It was 24m (79ft) long by 4.4m (14.5ft) beam and

some 23 tonnes displacement with an estimated speed of 14kph (7.6 knots)

when fully manned. The strakes were mounted on 7.5–12.5cm wide ribs at

9ocm centres but 45 cm apart near the stern, where a steering oar or rudder

had been fixed. A variety of iron fastenings had been used in the

construction—rib nails, keel plate spikes, steerage frame bolts, gunwhale spikes

and keel scarf nails and thole pins to form rowlocks for the oars. Once in

place, these were clenched over, after iron roves or diamond-shaped washers

had been placed over the shanks of the various fittings. The long axes of the

roves were all placed fore and aft in the vessel. The Sutton Hoo ship thus

shows a high degree of practical and artistic craftsmanship in Saxon days.

From the coins, it has been dated at about AD 630.

Some five centuries were to elapse, after its emergence in China, for the

rudder mounted on a sternpost to be adopted in Europe in the thirteenth

century. This was a great improvement on the steering oar for it was of larger

area and, being well beneath the water level, it was far less affected by the

waves. Simultaneous improvements in the rigging and an increase in hull size

meant that longer journeys could be undertaken. The properties of the

lodestone had been known since Roman times but it was not until the late

twelfth century that the compass began to appear in Europe as an aid to

navigation. The first crossing of the Atlantic was made by the Genoese

Christopher Columbus, then in the service of Spain, in 1492. He observed the

difference between magnetic and true north, a fact already known but now

confirmed from a different location.