Cutting Tool Technology Industrial Handbook by Graham T Smith_2 pptx

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (1.16 MB, 9 trang )

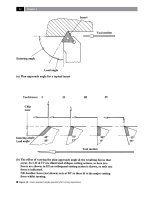

Figure 20. Insert approach angle geometry for turning operations.

Chapter

entering angle of 45° and lead angle of 45° is utilised,

giving rise to equal axial and radial component forces.

In ‘case II’ , the entering angle has changed to 75° and

lead angle is now 15°, these altered angles change the

component forces, with an increase in the axial force

while reducing the radial force. In ‘case III’ , an or

-

thogonal cutting action occurs, with only a 90° enter-

ing angle (i.e. the lead angle reduces to zero), showing

a large increase in the axial force component at the

expense of the radial force component which is now

zero

10

. In ‘case IV’ , an oblique cutting action has re-

turned (i.e. as in ‘cases I and II’), but here the entering

angle has changed to -15°, with the lead angle 75°, this

produces a large axial component force, but the radial

component force direction has now reversed. is last

tool plan approach angle geometry (i.e. ‘case IV’), is

similar to the geometry of a light turning and facing

tool, allowing cylindrical and facing operations to be

usefully undertaken – but the tool’s point is somewhat

weaker that the others, with the tool points becoming

of increased strength from right to le. erefore, in

‘case I’ , for a given feedrate and constant D

OC

, the cut

length/area is greater than the other ‘cases’ shown and

with this geometry, it enables the tool to be employed

for heavy roughing cuts. Returning to ‘case III’ , if this

tool is utilised for nish turning brittle-based work-

piece materials, then upon approaching the exit from a

cut, if the diameter is not supported by a larger shoul-

der diameter, then the axial component force /pressure,

will be likely to cause edge break-out (i.e. sometimes

termed ‘edge frittering’), below the machined surface

diameter at this corner (i.e. potentially scrapping the

machined part). In mitigation for this orthogonal cut-

ting tool geometry, if longer slender workpieces re-

quire cylindrical turning along their length, then with

the radial force component equating to zero, it does

not create signicant ‘push-o ’ and allows the part to

be successfully machined

11

.

A single-point turning geometry is subject to very

complex interactions and, as one geometric feature is

modied such as changing the entering angle, or in-

10 In all of these cases, it is assumed – for simplicity – that there is

no nose radius/chamfer on the tool and it is innitely sharp.

11 In order to minimise the eects of the radial force component

when cylindrically turning long slender workpieces with ‘Case

I and II’ tool geometries, the use of a programmable steady,

or a ‘balanced turning operation’ (i.e. utilising twin separately

programmable turrets on a turning centre, with tools situ-

ated virtually opposite each other running parallel during the

turning operation – see Fig. 41), will reduce this ‘push-o ’.

creasing the tool’s nose radius, this will inuence other

factors, which in turn could have a great impact on the:

type of machined surface nish produced, expected

tool life and the overall power consumption during the

operation. In fact, the main factors that inuence the

application of tooling for a specic turning operation

are:

I. Workpiece material – machinability, condition

(i.e. internal/external), mechanical and physical

properties, etc.,

II. Workpiece design – shape, dimensions and ma-

chining allowance,

III. Limitations – accuracy and precision require-

ments, surface texture/integrity, etc.,

IV. Machine tool – type, power, its condition and

specications,

V. Stability – loop stiness/rigidity (i.e. from the

cutting edge to its foundations),

VI. Set-up –

tool accessibility, workpiece clamping

and toolholding, tool changing,

VII. Tool programme – the correct/specied tool

and its tool osets, etc.,

VIII. Performance – cutting data, anticipated tool-life

and economics,

IX. Quality – tool delivery system and service.

In order to gain an insight into the complex and im-

portant decisions that have to be made when select-

ing tooling for the optimum production of either part

batch sizes, or for continuous production runs, then

the following section has been incorporated.

.. Cutting Toolholder/Insert

Selection

When deciding upon the correct selection of a tool-

holder/cutting insert for a given application, a range

of diverse factors must be considered, as indicated in

Fig. 21. As can be seen by the diagram (Fig. 21) and

associated text and captions, there are many other

variables that need to be considered prior to selection

of the optimum toolholder/insert. Generally, the xed

conditions cannot be modied, but by ‘juggling’ with

the variable conditions it is possible to accomplish the

best compromise toolholder/insert geometry, to opti-

mise these cutting conditions for the manufacture of

a specic workpiece and its intended production re-

quirements. Whenever toolholders and cutting inserts

are required for a specic manufacturing process, it

is important to view the tooling selection procedure

as a logical progression, in order to optimise the best

Turning and Chip-breaking Technology

Figure 21. The factors that must be considered prior to commencing a turning operation, when

utilising indexable inserts

.

Chapter

possible tools/inserts for the job in hand. Perhaps the

following selection strategy for a ‘start point’ in choice

and application of turning tools, can be undertaken

according by the following step-by-step approach:

Start Point

→ Edge clamping

system,

↓

Toolholder size

and type,

↓

Insert shape,

↓

Insert size,

↓

Nose radius,

↓

Insert type,

↓

Tool material,

↓

Cutting data

→

Final Tool-

holder and

Insert Selection

Edge Clamping System

Initially, the tool holder clamping system should be

selected to provide optimum performance in dier-

ent applications over a wide range of workpiece geom-

etries. e type of machining operation and to a lesser

extent, the workpiece size determines tool holder se-

lection. For example, roughing-out operations on big

components will make considerably dierent demands,

to that of nishing passes on small components.

NB

Pin, clamp and lever are just three of the insert

clamping systems available – consultation with the

tool suppliers at this point might be benecial.

Toolholder Size and Type

Once the clamping system has been selected, the size

and type of toolholder must be determined, with its

selection being inuenced by: feed directions (i.e. see

Fig. 22 for turning insert shapes and feed directions),

size of cuts, workpiece and toolholder situated in the

machine for accessibility requirements. e work-

piece’s shape plays a decisive role if surface contouring

is necessary, this is particularly relevant for machining

part access, as a toolholder is dened by its: eective

entering and point angles

12

, together with the insert’s

shape (see Fig. 22).

Toolholders should be the largest possible size for

the turning centre’s tool turret, this requirement is vi-

tal, as it reduces the ‘tool overhang ratio’ – providing

rigidity and integrity to stabilise the insert’s cutting

edge.

NB Appendix 1a shows the ISO ‘Code Key’ – for Ex-

ternal Toolholders.

Appendix 1b

shows the ISO ‘Code Key’ – for Solid

Boring Bars.

Appendix 1c

shows the ISO ‘Code Key’ – for Car-

tridges.

Insert Shape

e insert shape should be selected relative to the en-

tering angle needed for the tool’s accessibility, or ver-

satility. Here, the largest suitable point angle should

be chosen for strength and economy (see Fig. 23). In

Fig. 23, is illustrated a practical example of how chang-

ing only one variable – insert geometry (shape) – can

inuence an insert’s turning application. e shape

of an insert will determine its inherent weakness, or

strength, which is of particular relevance if rough-

turning operations are necessary. Furthermore, insert

shape will inuence whether it is prone to vibration, or

not and its predictable tool life. Hence, if one is con-

cerned about vibrations of either the tool, workpiece,

or both, then a weaker insert such as a light turning

and facing geometry with less cutting edge length ex-

posed in-cut, might be more suitable. Variable condi-

tions such as the selection of insert’s geometric shape

can aect other machining parameters and, this is

valid for other insert factors, so a compromise will al-

ways occur in any machining application.

12 Eective entering angles (κ

1

) must be carefully selected when

the operation involves proling, or copying. e maximum

proling angle (β) is recommended for each tool type – if

‘workpiece fouling’ is to be avoided.

NB κ

1 =

κ

+

β

(for plunging into a surface), whereas κ

1 =

κ

– β

(for

ramping-out of a surface), κ

1 =

κ

(β = 0°) for cylindrical turn-

ing, Where: eective entering angle (κ

1

), entering angle (κ),

maximum in-copy angle (β). Always select the smallest enter-

ing angle that the part geometry will allow.

Turning and Chip-breaking Technology

Figure 22. Tool paths in nish turning operations. [Courtesy of Sandvik Coromant].

Chapter

NB Appendix 1d shows the ISO ‘Code Key’ – for In-

dexable Inserts.

Insert Size

An indexable insert size is directly related to the tool-

holder selected for the operation, with the entering

angle and insert shape having previously been estab-

lished. Only the matching-shaped insert can be tted

into the seat of a particular toolholder, as its shape

and size are predetermined by the seating dimensions.

In roughing-out operations, the largest cutting depth

for a given toolholder, will inuence the insert size.

For any insert, the eective cutting length has to be

determined (see Fig. 20b), as the entering angle will

inuence the size of the insert selected. If the eective

cutting edge length is less than the depth of cut (D

OC

),

a larger insert should be chosen, or the D

OC

should

be reduced. Sometimes in more demanding turning

operations, a thicker insert – of the same geometric

shape – gives extra reliability.

Figure 23. Selecting indexable inserts for turning operations. [Courtesy of Stellram].

Turning and Chip-breaking Technology

Nose Radius

Of particular relevance in any turning operation is the

insert’s tool nose radius (r

ε

– see Fig. 17), as it is the key

factor with regard to:

•

inherent strength in roughing operations,

•

the resulting surface texture from nishing opera-

tions.

Further, the size of the nose radius aects vibrational

tendencies (see Fig. 23) and in certain instances, the

feedrates. e nose radius is the transition between the

major and minor cutting edges, which determines the

strength, or weakness of the point angle (see Figs. 16a

and 17), therefore it is an imperative factor to get right.

In general, roughing-out should be undertaken with

the largest possible nose radius, as it is the strongest

tool point (see Fig. 23). Further, a larger tool nose ra-

dius permits higher feedrates, although it is important

to monitor any possible vibrational tendencies. Later

in the relevant section, more will be said on the inu-

ence that the insert’s tool nose radius plays in the nal

machined surface texture, but it is worth mentioning

here that the feedrate for roughing operations should

be set to approximately half the size of the nose radius

utilised. e size of the nose radius has an aect on the

power consumed in turning in conjunction with the

material’s yield strength and chip-forming ability, par-

ticularly in rough-turning operations. e maximum

material removal rate (MMR) can be obtained by a

combination of high feedrate, together with a moder-

ate cutting speed, with other limiting factors, such as

depth of cut (D

OC

), tool’s nose radius, under consider-

ation. Oen, the machine tool’s power (P) availability

c

an sometimes be a limiting factor when mmR is the

requirement and, in such circumstances the cutting

speed is usually lowered somewhat. For a given nose

radius and cutting insert geometry, the power can be

derived, to ensure that the machine tool will be able

t

o cope with this pre-selected mmR, in the following

manner:

Machine tool’s power requirement (P):

P =

tangential force (F

T

) x cutting speed (V

C

)

P =

F

T

× V

C

P = k

C

× A × V

C

∴ P = k

C

× f × a

P

× V

C

(kW)

Where:

f =

feed/rev (mm/rev)

a

P

= depth of cut (mm)

Cutting speed (V

C

)

V

C

= πDN/1000 (m/min)

Where:

D =

workpiece diameter (mm)

N =

workpiece rotational speed (rpm)

Specic cutting force (k

C

):

k

C

= F

T

/A (N/mm

2

)

Where:

A =

cutting area (mm

2

)

For example, for nishing operations, with the nose

radius in combination with the feedrate (i.e. pre-se-

lected), this will aect the surface texture and part ac-

curacy, in the following manner:

Machined surface texture (Rt):

(Rt, this parameter being: maximum prole height)

Rt =

f

2

/8 × r

ε

x 1000 (µm)

Where:

f

2

= feedrate per revolution (mm/rev)

r

ε

= nose radius (mm)

NB e surface texture parameter ‘Rt’ ,

can be con-

verted into other surface texture parameters – as nec-

essary.

By utilising either: larger turning insert tool nose ra-

dius, ‘wiper insert’ (yet to be discussed), a more posi-

tive plan approach angle, or in certain circumstances,

a higher cutting speed, the surface texture can be im-

proved. In general, the coordination of the tool’s nose

radius and the pre-selected feedrate in nishing op-

erations, indicates that the feed should be kept below

a certain level to achieve an acceptable machined sur-

face texture value.

Insert Type

e cutting insert type is for the most part determined

by the previously selected geometry – see Appendix 1d

for the selection of indexable inserts. In reality, vari-

ous cutting conditions and workpiece materials make

dierent demands on the insert’s cutting edge. For ex-

ample, when machining hardened steel parts, this will

be completely dierent from that to the machining of

aluminium components.

48 Chapter 2

Once the insert shape has been established in con-

nection with its plan approach angle together with the

nose radius dimension, this just leaves the type of ge-

ometry to be found. In this instance, the type of insert

geometry refers to the ‘working area’ (i.e. nominally

found by its depth of cut and feedrate – more will be

said concerning this topic later, when ‘chip-breaking

envelopes’ will be discussed). Additional factors can

inuence the type of cutting geometry choice, such

as: machine tool’s condition, its power, the stability of

the workpiece-tool-machine set-up, other factors that

could aect geometry selection include: whether con-

tinuous, or intermittent cutting occurs, any tendency

toward vibration while machining. Turning operations

can be separated into a number of ‘working areas’ , be

-

ing based upon the removal of workpiece material and

the generation of accurate machined component di-

mensions, in combination with specic surface texture

requirements – as shown in Table 3.

When establishing an insert type, the feedrate

and depth of cut should be identied with one of the

‘working ranges’ (i.e. from Table 3), as the various in-

sert types to be chosen relate to this chart. It should

be borne in mind that the most suitable ‘working area’

selected, will vary, in combination with such factors as

the insert’s: size, shape and nose radius.

Tool Material

e penultimate evaluation to be made concerning

tooling decision-making is the choice of insert mate-

rial, or combination of materials that constitute the

cutter’s tool edge. Today, manufacturers of tooling

have a strategy for continuous improvement with varia-

tions in both tool matrices and coatings being consid-

erable. Not only are cutting tool material research and

development an on-going intensive activity, but their

application for wider ranges of machining applica-

tions are being considerably enhanced. A brief review

of just some of the current tool materials and coatings

have been previously mentioned in Section 1.2, with

the main range of cutting tool materials being: ce-

mented carbides, coated cemented carbides, ceramics,

cermets, cubic boron nitride, polycrystalline diamond

and monolithic (i.e. natural) diamond.

NB

A good ‘start-point’ for most machining opera-

tions, is to consider coated carbides initially, then if

these grades prove unsatisfactory, for whatever reason,

select one of the other materials – perhaps aer con-

sultation with a cutting tool manufacturer, or aer a

machinability testing procedure.

Cutting Data

Once all of the physical, metallurgical and geometrical

factors for the cutting tool have been established for

the machining operation, then it is necessary to set, or

calculate the cutting data – oen these criteria can be

found from tooling manufacturers recommendations

and cutting data tables. Certain variable factors such as

feedrate should have already been made, allowing the

cutting speed to be calculated, from the well-known

expression (below):

V

C

= πDN/1000 (m min

–1

)

Where:

V

C

= cutting speed (m min

–1

)

D = Workpiece diameter (mm)

13

N = rotational speed (rpm)

13 In the case of drilling, reaming and tapping operations, it is

the diameter of the cutting tool that is used in the calculation.

For any other internal machining operations – such as in bor-

ing, it is the initial hole diameter that is employed in the cut-

ting speed calculation.

Table 3.

Typical working areas for external turning opera-

tions

Type of machining

operation:

Feedrate (f): Depth of cut

(D

OC

):

Extreme nishing 0.05 to 0.15 0.25 to 2.0

Finishing 0.1 to 0.3 0.5 to 2.0

Light roughing 0.2 to 0.5 2.0 to 4.0

Roughing 0.4 to 1.0 4.0 to 10.0

Heavy roughing >1.0 6.0 to 20

Extremely heavy roughing >0.7 8 to 20

(mm) (mm)

[Courtesy of Sandvik (UK) Ltd]

.

Turning and Chip-breaking Technology

Once again, manufacturers data tables are oen useful

‘starting-points’ for estimating the initial cutting pa-

rameter information. Considerable care must be taken

if the material has either a high work-hardening ten-

dency, or intrinsic bulk (i.e. workpiece material) hard-

ness, as this can inuence the numerical data selected.

Moreover, the plan approach angle also has an eect

on the numerical value for the parameter, for example,

oblique machining allows a higher value than for or-

thogonal machining.

2.2 History of Machine Tool

Development and Some

Pioneers in Metal Cutting

.. Concise Historical Perspective

of the Development of Machine

Tools

Toward the end of the 1700’s, any high-quality machin-

ing at the time meant tolerances of 0.1mm being con-

sidered as ‘ultra-precision’ , with this level of tolerance

having steadily improved from the beginning of the

Industrial Revolution. Pioneers in machine tool devel-

opment such as John Wilkinson (1774), developed the

rst boring machine, this being capable of generating

a bored hole of 1270 mm in diameter, with a error of

about 1 mm. A contemporary of Wilkinson, namely

Henry Maudslay (1771–1831), invented many preci-

sion machine tools, but he was particularly noted for

the design and development of the rst engine lathe.

Slightly later, Sir Joseph Whitworth (1803–1887), de-

veloped the rst modern-day Vee-form screwthread

and nut (i.e. 55° included angle – ‘Whitworth thread’),

thereby enabling precision feed-motion to be achieved

via suitable gear trains on such machine tools. ese

early fundamental advances in machine design, al-

lowed others and in particular, Joseph R. Brown

(1852) to design the ‘dividing engine’. is newly-de-

veloped equipment, allowed precision engraving of

the hand dials on machine tool axes, enhancing them

with much better machinist’s judgment in both rotary

and linear control, in combination with consistent

repeatability by the skilled operative. Shortly aer

these developments, Eli Whitney produced the origi-

nal milling machine, which was rened still further

by the Cincinnati Screw and Tap Company in 1884.

is ‘Cincinnati machine’ was a direct forerunner of

today’s manual controlled knee-type milling machine

tools. Of particular note was the ergonomic grouping

of the controls centrally for a more ecient hand con-

trol by the skilled operator. At this time the machine

tool still utilised the Vee-form screw thread, with the

Acme-form (ie having the ability to take-up backlash)

still someway o development.

Steady development and renement of a range

of machine tools continued into the the rst half of

the 20

th

century until the next major ‘milestone’ oc-

curred. is signicant development was the ‘modern’

numerically-controlled (NC) machine. Around the late

1940’s, the ‘recirculating ballscrew’

14

was designed so

that it could take-up backlash in both directions of

rotation for machine tool axes. ese early ‘ballscrews’

were tted to a converted Cincinnati Milling Machine

Company’s ‘Hydro-Tel’ die-sinking machine tool,

at MIT (Massachusetts Institute of Technology).

is military research-funded project having been

commissioned by the United States Air force – who

required complex free-form aeronautical parts to be

automatically machined for the latest aircra. is

research was undertaken by MIT, in association with

‘Cincinnati’ and the Parsons Tool Company. e

binary-coded punched-paper tape, controlled the

simultaneous machine tool axes using alpha-numeri-

cal characters (ie the forerunner of today’s programs

using ‘G- and M-coded’ CNC controllers), through a

14 Who, when and where ‘recirculating ballscrew’ design and

development took place is open to some debate. As propo-

nents in the UK say it was Alfred Herbert and Sons, whereas

in the United States, the Parsons Tool Company are oen

quoted as the originators. However, what is not in question,

is that with its unique ‘Gothic’ arch’ (i.e. Ogival geometry),

having point contacts between the screw and the adjacent re-

circulating balls, allows the assembly to be pre-loaded in-situ,

thereby eliminating any appreciable backlash allowing accu-

rate control of these axes.

NB e previous Acme taper thread (i.e. 29° included angle)

tted to ‘conventional’ machine tools had an eciency of

no better that 40% – with backlash present, whereas today’s

hardened ‘ballscrews’ have eciencies of ~90%, coupled to

an impressive rigidity (~900 N µm

–1

) and minimal ‘stick-slip’ ,

therefore minimising the so-called ‘ballscrew wind-up’ due to

the action of torque-eects in combination with the cutting

forces.

Chapter