Drilling and Associated Cutting Tool Technology Industrial Handbook_5 potx

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (866.01 KB, 9 trang )

e insert’s substrate – if cemented carbide – re-

quires some thought, as if it is too hard, this type of

insert may chip via the eects of machining vibrations,

this is particularly so, if the tool geometry has an ex-

tra-positive and sharp insert cutting edge. It might be

more prudent to initially choose a medium-hard ce-

mented carbide grade, as it tends to cope with a poten-

tial edge-chipping condition more readily, then, if this

proves successful, a harder grade may be selected.

Cutting Parameters – Decisions

Two complementary cutting parameters are the insert’s

nose radius and the inuence it has on the D

OC

. For

Figure 62. Interchangeable cutting heads for machining internal features. [Courtesy of Sandvik Coromant].

Drilling and Associated Technologies

example, when a nish boring operation is required,

then it is recommended that both a small nose radius

and D

OC

is used. is smaller boring insert nose ra-

dius, minimises contact between the workpiece and

insert, resulting in lower tangential and radial cutting

forces. For ne-boring applications, a good start point

is to choose an insert with a 0.4 mm nose radius, with

a 0.5 mm D

OC

. It should be noted that the D

OC

ought to

be larger than the nose radius, this is because if it was

the other way around, cutting forces would be directed

in a radial direction – increasing potential vibrational/

bar-bending (i.e. push-o

42

) problems.

Feedrates should be identical regardless of tool’s

overhang, as any feed selection is normally based upon

the insert’s chip-breaking capabilities. Avoidance of

very high feedrates when rough boring is necessary, as

it can signicantly increase the tangential cutting force

component. For nish boring operations, it is normally

the workpiece’s surface texture requirement that dic-

tates the maximum feedrate that can be utilised. More

will be mentioned on the machined cusp height’s eect

on surface texture, this being created by the remnants

of the partial nose arc (i.e. radius) of the cutting insert

and the periodic nature of the selected feedrate on the

bored workpiece’s surface, later on in the relevant sec-

tion in the book.

A mistake oen made by setters/machinists in

order to attempt to

minimise vibrational tendencies, is

to reduce the rpm. is strategy will not only decrease

productivity, but the lower rotational speed can lead

to BUE formation, which in turn, modies the insert’s

cutting geometry and could change the cutting force

directions. Instead of rpm reductions, modication

of other cutting data variables is suggested, in order

to improve these adverse vibrational/chatter eects.

Sometimes even increasing the rotational speed, can

eliminate unwanted chatter.

Although it is not a specic cutting performance

parameter, an oen disregarded measure is that of

boring bar tool clamping. In many circumstances, cy-

lindrical boring bars are simply clamped with several

setscrews, this is a poor choice of clamping method, as

at best, setscrews only contact about 10% of the boring

bar. Conversely, a split-tool block, clamps along almost

42 ‘Tool push-o ’ – oen termed ‘spring-cuts’ , are the result of

tool deection, particularly when light cuts are used. To mini-

mise the ‘push-o’ , very rigid workpiece-machine-tool setup

with a smaller nose radius to that of the D

OC

is recommended.

all of the boring bar’s periphery in the toolpost, allow-

ing much greater tool rigidity and cutting stability, al-

leviating many of the potential problematic in-service

machining conditions.

.. Multiple-Boring Tools

Twin cutting insert tooling, usually consists of a cy-

lindrical shank with slides mounted at the front (Fig.

63a), or a U-shaped bar with cartridges (Fig. 63b). e

slides and cartridges can be radially adjusted, allow-

ing for a range of various bored diameters to be ma-

chined. Normally, such tooling has a 7 mm maximum

cutting depth recommended – for both edges simul-

taneously in-cut. With Twin-edged boring tools the

cartridges can be so arranged, that ‘Step-boring’

43

can

be utilised.

When large diameter component features require

a boring operation, then the ‘Divided-version boring’

tooling can be exploited, but diametral accuracy is not

as good as for some of the other types of boring tool

designs. An advantage of the Divided-version’ boring

tools, is the fact that a large diameter range can be cov-

ered, with this single tool. If a ‘Universal ne-boring’

tool is utilised (Fig. 63b), either internal (Fig. 63b-top),

or external machining (Fig. 63b – bottom), can be un-

dertaken. In this case, the ne-bore cartridges (1) are

mounted on a radially-moveable slide (2), which is

mounted on a bar (3). In the latter case of external com-

ponent feature boring, there is a physical limit to the

minimum diameter that can be machined – this being

controlled by the bar’s actual size. (i.e. Here, it should be

said that this particular tooling ‘setup’ can be thought

of as virtually a Trepanning operation with a boring

tool). Moreover, with this external nishing operation,

the spindle must rotate in a le-hand rotation.

Tri-bore tooling oen having individual micro-bore

cartridge adjustment (i.e. not shown), as its name im-

plies, uses three cutting inserts equally-spaced at 120°

apart. is boring tool arrangement of cutting inserts,

oers very high quality bored diametral accuracy and

43 ‘Step-boring’ , refers to using special shims with one of the

cutting inserts axially situated a little way in front of the other,

while at the same time, the cartridges are radially adjusted en-

abling the front insert to cut a slightly smaller diameter to that

of the rear one. It should be noted that when ‘Step-boring’ , the

maximum D

OC

is normally 14 mm, with an associated feedrate

of 0.2 mm rev

–1

.

Chapter

Figure 63. Twin-edged boring tooling. [Courtesy of Sandvik Coromant].

Drilling and Associated Technologies

precision to the machined hole, but such tooling can

be somewhat more costly than when utilising a single-

insert tool.

.. Boring Bar Damping

For boring bars that have an L/D ratio of <5:1, then

relatively stable cutting conditions with controllable

vibrational inuences can be tolerated. However, if L/D

ratios utilised are larger than this limiting value, then

potentially disastrous vibrational tendencies could oc-

cur, leading to a variety of unwanted machining and

workpiece characteristics, these include:

•

Limited tool life – caused by forced and self-excited

vibrations, restricting both cutting eciency and

tool life,

•

Unacceptable machined surface texture – vibra-

tions in the form of workpiece surface chatter, can

be the cause for component rejection,

•

Substandard machined roundness – vibration/

chatter eects creating high-frequency harmonic

44

eects on the roundness prole.

Stiness can be expressed in terms of either static, or

dynamic stiness. Static stiness of a bar is its ability to

resist a bending force in a static condition, conversely,

dynamic stiness is the bar’s ability to withstand os-

cillating forces (i.e. vibrations). Dynamic stiness is an

essential property for a boring bar, as it is a measure of

its capacity to dampen the vibrations occurring during

machining, being greatly dependent of its overhang. As

one would expect in testing for dynamic stiness, with

44 ‘Harmonics’ – on a machined component are the product

of complex interactions, including method of manufacture:

component geometry, cutting data utilised, any vibrational

inuences encountered and material composition and its

manufacture (e.g. Powder Metallurgy parts can vary in both

porosity and density throughout the part, which may aect, or

locally destabilised the cutting edge).

NB Harmonics on the machined workpiece, can be thought

of as a uniform waveform (i.e. sinewave) that is superim-

posed onto the part’s surface. e part’s low frequency harmo-

nicoen has higher frequency harmonics superimposed onto

the roundness. For example, a 15 undulation per revolution

(upr) harmonic, could have a 500 upr harmonic superimposed

onto it, requiring suitable a Roundness Testing Machine with

Gaussian lters to separate out the respective harmonic con-

ditions – for metrological inspection and further analysis.

a boring bar’s overhang increasing under standardised

machining conditions, the amplitude will also increase.

However, if the boring bar was dampened in some

way, perhaps by utilising a ‘shock-absorber eect’ , ma

-

chining could be undertaken at longer overhangs. is

‘damping eect’ is indicated by the highly centralised

amplitude of oscillatory movements quickly reducing

with time, indicating a high level of dynamic stiness,

this being crucial for long L/D ratios. Obviously, the

boring bar’s cutting edge deection at its tool tip, is

directly related to the amount of bar overhang, this de-

ection being the result of the applied cutting forces.

e magnitude of a boring bar’s deection being de-

pendent upon: bar composition, diameter, overhang

and the extent and magnitude of tangential and radial

cutting forces. e rigidly clamped and cantilevered

boring bar’s ‘free-end’ will deect/deform by forces

acting upon it and, some idea of the magnitude of this

deection can be gleaned by the simple application of

‘mechanics of materials’ , using the following formula:

F L

E I

(mm)

Where:

∆ = Boring bar deection (mm),

F = Cutting force (N),

L = Boring bar overhang (mm),

E = Bar material’s coecient of elasticity (N mm

–2

),

*I = Moment of Inertia (mm

4

).

* For a boring bar of circular cross-section, the Mo-

ment of inertia will be:

I = π × D

4

/64 (mm

4

).

For example, assuming that if a φ25 mm steel boring

bar has an L/D overhang of 4:1, with an applied cut-

ting force of 100 kP, then the magnitude of bar deec-

tion, using the above formula, would be:

∆

L = 4D

= 0.083 mm.

If the overhang of this boring bar was now increased

to L/D ratios of 7:1 and 10:1, respectively, this would

produce tool tip deections of:

∆

L = 7D

= 0.444 mm

∆

L = 10D

= 1.293 mm.

Hence, these deection values emphasise the impor-

tance of reducing overhang as it increases by approxi-

mately ‘cube’ of the distance. Moreover, deection can

Chapter

also be reduced by utilising a dierent boring bar ma-

terial, as this will improve its coecient of elasticity

45

.

In boring-out roughing operations, any vibrations

present are only a problem if they lead to insert dam-

age. For nish-boring operations, vibrational condi-

tions that may occur could be the dierence between

success and failure for the nished machined part.

So, the boring bar’s ability to dampen any vibrational

source becomes imperative, once a ne-boring opera-

tion is necessary. Vibrations can occur in any number

of ways that could aect the boring operation, from

the constructional elements of the machine tool,

through to slideways, or their recirculating ball bear-

ings, etc Hence, the joints in a machine tool can be

regarded as a complicated dynamic system, with any

slideway motion of vibrating contact faces, necessitat-

ing lubricating oil to not only reduce any stiction and

frictional eects, but to help dampen these structural

elements. Machine tool builders are acutely aware that

certain machine tool materials ‘damp’ more readily

than others. Cast iron and in particular ‘Granitan’ (i.e.

a product of crushed granite and epoxy resin), can pre-

dominantly act as built-in dampening media for any

vibrational sources present. e main source for any

vibrations in boring, results from the long overhangs,

necessary to machine the hole depth of the compo-

nent’s feature. erefore, the magnitude of vibrations

in the overall system result from the dampening capa-

bilities of the actual boring bar.

Tuned Boring Bars

A boring bar that has been ‘tuned’ , has the ability to

dampen any generated vibrations between the work-

piece and the cutting edge while machining. e

‘dampening eect’ is achieved through a vibration ab-

sorbing device (i.e see Figs. 61a and 62b), this has the

consequence of increasing the bar’s dynamic stiness,

giving it the ability to withstand oscillating forces. e

45 Coecient of elasticity, for a steel boring bar composition,

E = 21 × 10

4

(N mm

–2

), conversely, using a cemented carbide

material for an identical boring bar, E = 63 × 10

4

(N mm

–2

), giv-

ing three times greater stiness, allowing much greater boring

bar overhangs.

NB In reality, the boring bar’s deection will be higher than

the values given in these examples, as the formula is based

upon the assumption that the bar is absolutely rigidly clamped,

which is impossible to achieve.

method of achieving this bar damping has already been

mentioned in Section 3.2.1, with the relationships be-

tween the size of the bar’s body, suspension, viscosity

of the liquid media, being carefully designed by the

tooling manufacturer. During the boring operation,

the vibrations set the body in oscillation. Hence, the

body and the liquid alternate, taking each others place

in the space within the actual boring bar. A pattern is

established during boring, where the oscillations of the

body are not in harmony with the vibrations resulting

from machining. is out-of-harmony, means that the

vibrations are virtually neutralised – to an acceptable

level – via the kinetic energy being transformed by the

‘system damping’. Any vibrations present during bor-

ing, are relative to the amount of bar overhang, there-

fore on longer boring bar lengths, they are normally

tted with some means of adjustment, so that they can

be ‘tuned’ to the frequency occurring within its range.

e simplest manner of achieving adjustment, is by

a rotation of a lockable set screw, which when either

tightened, or slackened, aects the suspension of the

body in the liquid, thus ‘tuning’ the boring bar to the

actual machining conditions present.

.. ‘Active-suppression’

of Vibrations

As has been stated at the beginning of Section 3.2.4, if

boring bars have an L/D ratio >5:1, then vibrational ef-

fects may result in tool chatter. It has been observed in

experimental work, that the boring bar’s tip produces

a vibration motion that follows an elliptical path in the

plane normal to the longitudinal axis of the bar. e

ratio of the amplitude of vibration along the major and

minor axes varies with cutting conditions, further-

more, the inclination of these axes to the ‘radial line’

of the tool also varies. Of signicance, is the fact that

the build-up of chatter will begin almost immediately,

even before one revolution of the workpiece has oc-

curred. is build-up continues almost evenly until

some limiting amplitude occurs, which suggests that

the well-known ‘Orthogonal mode coupling’ is pres-

ent, further, with the phase dierence between the vi-

brations causing an elliptical tool tip path, the vibra-

tional energy is fed into the tool-workpiece system,

promoting self-excitation.

As has been suggested, the dynamic stability of the

boring bar is of prime importance, with the onset of

self-excited chatter, being governed by the ‘Multiple

regenerative eect’ , which is a function of the so-called

Drilling and Associated Technologies

‘space phase’. is ‘space phase’ condition, is the phase

of vibration around respective turns of work, uctu-

ating between 90° and 180° and is equal to the phase

between the inner and outer modulation. Moreover,

it has been shown that by modifying the workpiece’s

rotational speed, this disturbs the ‘space phase’ and,

consequently inuences the ‘time phase’ , leading to

a reduction in self-excited chatter. It has been practi-

cally demonstrated that by modifying the peripheral

speed of the workpiece, this technique is only partially

successful in alleviating chatter. More success can be

made by utilising damped boring bars, such as the

‘Lanchester’ type

46

, with dynamic vibration absorbers

(DVA’s), to really suppress vibrational inuences dur-

ing the boring process.

Some progress has been made on the development

of DVA techniques, but the potential ‘step-change’

will occur in vibrational suppression for boring bars,

when the improvement of production versions of ‘ac-

tive’ dampers for such tooling becomes a reality. Just

such a potential ‘active’ boring bar is shown schemati-

cally in Fig. 64. Invariably, the boring bar has a supply

of energy to it – via an external source, that controls

the cutting edge’s position by monitoring the feedback

of the relative displacement of tool’s edge with respect

to the workpiece. In later research work by Matsubara

et al. (1987), chatter suppression was analysed for the

boring bar using ‘feed-forward’ control of the cutting

force. Further, the cutting edge was positioned in re-

sponse to this force, with these type of ‘active’ control

systems being known as: ‘Cutting edge positional con-

trol systems’.

Typical of a vibrational control approach is illus-

trated by the ‘active’ boring bar already mentioned and

depicted in Fig. 64, where the forces are damped in re-

sponse to the vibrational velocity of the cutting edge,

which has been termed a: ‘Vibrational velocity control

system’. In this damping technique, the boring bar sup-

pression is by a series of piezo-electric elements that

act as ‘active dampers’. Such a ‘damper’ responds to

onset of chatter vibration (i.e. the high-energy com-

ponents). Moreover, the damping force achieves opti-

mal phase dierence, since the phases between both

46 ‘Lanchester boring bars’ , normally utilise an internal metal

slug which is usually surrounded by some form of: liquid/uid

medium, DVA’s, or more primitively, sprung-loaded and as

such, the slug is free to move out-of-phase with the cutting

conditions, dictated by the boring bar’s applied cutting forces,

thereby the onset of chatter will be potentially ‘cancelled out’.

the ‘damping’ and vibrational forces are controllable.

is type of ‘active’ boring bar arrangement, achieves

directional damping characteristics via its ‘dampers’ ,

here they control two ‘degrees of freedom’

47

via the ‘Re-

generative feedback loop’ , which diminishes oscillatory

motion (i.e. harmonics), by careful control of energy

losses.

In recent years with the advent of articial intelli-

gence (AI) applications to major industrial engineering

problems, and more specically, in the performance

and robustness of certain types of ‘Neural networks’ ,

the goal of obtaining some form of real-time monitor-

ing and control in the machining process is now closer

to reality. ese AI systems have been successfully

utilised for applied research applications to tool wear

monitoring in turning tool operations – aer suitable

‘training’ of a pre-selected neural network architecture.

ese ‘networks’ could be successfully applied to bor-

ing bar vibrational monitoring and control situations.

More detailed information will be said on how, where

and when Neural network decision-making and, why

these cutting tool monitoring applications should be

utilised in the production environment, later in the

text.

.. Hard-part Machining,

Using Boring Bars

Although ‘hard-part’ turning has been utilised for

some considerable time, with the advent of polycrys-

talline cubic boron nitride (PCBN) tooling, etc., it has

seen little in the way of exploitation for boring opera-

tions, to date. One of the major reasons for this lack

of tooling application, is because most hardened parts

are in the region of hardness values ranging from 42

to 66 HR

C

. Such high component hardness, requires

considerable shearing capability by the tooling to suc-

cessfully machine the excess stock from the workpiece.

Generally, the robust nature of toolholding for turning

47 ‘Degrees of Freedom’ , the ‘free-body kinematics’ , exhibit 6 de-

grees of translatory (i.e. linear) motions in space, these are: back-

ward/forward, upward/downward and leward/rightward.

NB Of some interest but in the main, to machine tool build-

ers for the purposes of volumetric calibration, are the rotary

motions of: yaw, pitch and roll, giving 18 degrees of freedom,

together with the 3 squareness errors, totalling 21 possible de-

grees of freedom.

Chapter

Figure 64. An ‘active’ boring bar and their capacity to suppress vibrational eects on boring holes [After. Mat-

subara; Yamamoto and Mizumoto; 1987]

.

Drilling and Associated Technologies

tools with their modest overhangs, does not present in-

surmountable diculties during machining, however

for the much longer overhangs associated with boring

operations (i.e. see Figs. 62a and 65a), then the cutting

forces generally dictate, short L/D ratios of <5:1 and

relatively large and robust boring bars (Fig. 65b).

ere are considerable diculties to be over-

come when any form of hard-part machining is

required – particularly for boring operations, when

the components have been either case- or through-

hardened, these are:

•

High temperatures in the cutting zone – necessitat-

ing high temperature resistant and thermally-sta-

bility of cutting insert materials,

•

Cutting force magnitudes are both higher and more

variable – robust cutting edge geometry is neces-

sary to withstand these increased shearing/cutting

force demands on the insert,

•

Small chip cross sections – these exert high pres-

sure near the insert’s cutting edge, oen necessitat-

ing an edge preparation to the insert’s corner,

•

Greater tool wear rates – oen more rapid cutting

edge wear, or the tendency to catastrophic break-

down of the insert,

•

Workpiece stresses during cutting – these stresses

are released during machining and may present

localised geometric variations to the nal shape of

the part,

•

Poor homogeneity in the workpiece material

– hardness variations across and through the part

(e.g. dierential case hardened depths), can lead to

signicant and variable cutting force loadings on

the boring insert,

•

Insucient stability – if the ‘machine-tool-work-

piece loop’ is not suciently robust, then due to the

greater cutting forces when hard-part machining,

Figure 65. Boring bar operational limitations and hard part boring at relatively high speed. [Cour-

tesy of Sandvik Coromant]

.

Chapter

this creates potential tool deection which could

become a major problem.

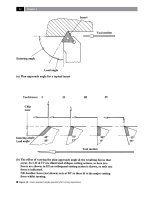

Boring Bar Deflection

When any boring operations take place, even with a

very rigid tool mounting and a small boring bar over-

hang, some vibration and tool tip deection will in-

evitably occur, this is exacerbated by machining hard-

parts. e former problem of vibration has previously

been mentioned and methods of minimising it are

possible. However, tool deections are more dicult,

if not impossible to completely eliminate, with these

longer cantilevered tools. Of note regarding overhang-

ing tool deections, are that a tool tip deects in two

directions (i.e. see Fig. 66a), these are:

•

Radial deection (∆

T

) – aects the machined (i.e.

bored) diameter,

•

Tangential deection (∆

R

) – causes the tip to move

downward for the centreline.

In each of these tool tip deections, both the size and

direction of the cutting forces are inuenced by the

chip thickness and insert geometry selected (i.e. illus-

trated in Fig. 66b). e radial deection will be equal

to the dierence between the diameter which was orig-

inally set and the actual bored diameter, this can be

easily found by the simple expedient of measuring it,

then adjustment can be made for this apparent deec-

tion. e tangential deection of the boring bar’s tip

can be established by either ‘direct’ , or ‘indirect’ met

-

rological techniques at the tool’s tip. In Fig. 66a, the

graph depicts deections ‘∆’ (i.e. both the tangential

‘∆

T

’ and radial deection ‘∆

R

’), as a function of the

cutting depth ‘a

P

’. Due to the fact that the tangential

deection (∆

T

) linearly increases with increasing D

OC

(a

P

), it is usually recommended that machining passes

are divided into a number of cuts when close toler-

ances are needed (i.e. in the region of IT7

48

) – see Table

5

49

for an abridged version of the IT tolerances, with

*Rmax values in µm.

e magnitude of radial deection as a function

of the cutting depth, is also inuenced by the ratio

between the insert’s nose radius and the D

OC

(a

P

), to-

gether with the boring insert’s entering angle. In some

cases, a boring bar is situated slightly above the work-

piece centreline, so that when it enters the cut at full

depth it will have tangentially-deected to the actual

48 ‘IT’ (i.e. in units of µm) – represents the average value of the

basic tolerance for the ‘diameter range’ in question. Hence, it

will vary according to the choice of diameter range selected.

49 ese values are related to surface texture expression of:

*Rmax (µm), which is: e maximum individual peak-to-val-

ley height. e Rmax values (i.e. in Table 5) can be calculated

from the IT value, using the following equation, rather than

the conventional equation: Rmax = (fn

2

/r

ε

) 125

this equation tends to give excessively high surface texture va-

lues, thus more practical values related to IT are to be found

from:

�

Rmax

IT

n IT

(µm)

Where: n = e number of IT’s.

Table 5:

IT values related to the basic tolerance for various diameter ranges

Dc (mm): Over /up to

-/3

Over/up to

3/10

Over/up to

10/50

Over/up to

50/180

Over/up to

180/400

Over/up to

400/800

IT5 0.6 0.8 1.3 2.2 3.2 4.5

IT6 0.9 1.2 1.9 3.1 4.6 6.4

IT7 1.4 1.9 3.1 5.0 7.4 10.1

IT8 2.0 2.9 4.7 7.8 11.5 15.8

IT9 3.6 7.5 9.4 12.4 18.3 25.2

IT10 5.7 7.6 12.1 20.0 29.8 40.5

IT11 8.6 11.8 19.1 31.4 46.2 63.8

[Source: Sandvik Coromant (1995)]

.

Drilling and Associated Technologies