Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_2 docx

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (518.01 KB, 9 trang )

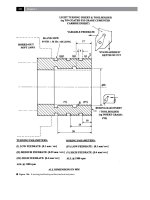

Figure 146. A turning and boring surface texture test piece.

Chapter

Figure 147. Machinability testing utilising an ‘accelerated testing procedure’ – a combination of the rapid facing and degraded

tool tests

.

Machinability and Surface Integrity

on a moderately short timescale. Normally in many

previous testing programs, an uncoated cemented car-

bide P20, or P10 grade would have been used, since

these grades withstand both higher speeds and have

better tool wear resistance to that of previously utilised

cutting tool materials. However in this case, an P25

grade was chosen, which is a degradation from the

optimum P20 grade, but it should still perform satis-

factorily. Furthermore, the cutting speed was raised by

>2.5 times the optimum of 200 m min

–1

, with all fac-

ing operations being conducted at a ‘constant surface

speed’

12

of 550 m min

–1

.

Typical tool-life curves produce by the AWT tech-

nique are illustrated in Fig. 148, showing the expected

three stages of ank wear. is ank wear being a func-

tion of: the initial edge breakdown, steady-state wear –

as the insert’s ank progressively degenerates and -

nally, catastrophic insert edge breakdown – as the edge

completely fails. Detailed metallurgical analysis can be

made as to the reasons why some P/M compacts per-

formed better than others, by reference to the litera-

ture on the metallurgical interactions between the tool

and the compact – this subject being outside the scope

of the present discussion. e facing-o secondary

machining operation meant that aer 10 facing passes,

a pre-programmed ‘optional stop’ can then be applied,

to allow both tool ank wear and compact surface tex-

ture to be established. e faced-o surface texture re-

sults can then be superimposed onto the same graph –

for a direct comparison of ank wear and for that of

the machined surface texture parameter. Without go-

ing into too much detail of the specic aspects of the

processing and metallurgical interactions present here

on the composite graph, some compacts abraded the

cutting insert more than others, while the ‘faced’ sur-

face texture, generally seemed to get worse, then im-

prove and nally worsen again. However, this is a

complex problem which goes to the ‘heart’ of the vi-

12 ‘Constant surface speed’ , this can be achieved by employing

the appropriate ‘canned-cycle’ G-code accessed from the CNC

controller, which allows the testpiece’s rotational speed to in-

crease as the faced diameter decreases*.

* Normally there is a restriction on the rotational speed limit

– created by the maximum available speed for this machine

tool, which would normally be reached well before the cutting

insert has coincided with that of components centre line, but

because in this instance, the compacted testpiece is hollow, the

rotational restriction does not present a problem.

sual aspect of machined surfaces – wherein the real

situation is that surface texture continuously degen-

erates, and it is only the burnishing (i.e.‘ironing’) of

the surface that ‘masks’ the temporary improvement

in machined surface – more on this topic will be made

in the surface integrity section. What is apparent from

using the AWT technique is that on a very short tim-

escale, considerable data can be generated and applied

research assessments can be conducted both speedily

and eciently. is topic of exploiting the minimum

machining time and data-gathering activities to gain

the maximum information, will be the strategic mes-

sage for the following dialogue.

Machinability Strategies: Minimising Machining

Time, Maximising Data-Gathering

Prior to commencing any form of machinability tri-

als, parameters for cutting data need to be ascertained

in order to minimise any likelihood of repetition of

results, while reducing the amount of testpieces to be

machined to the minimum. Data obtained from such

trials must be valid and to ensure that the cutting pa-

rameters selected are both realistic and signicant a

disciplined experimental strategy based upon the ‘De-

sign of Experiments’ (DoE) approach is necessary – see

Fig. 149. Here, a ow-chart highlights the step-by-

step approach for a well-proven industrial technique,

to maximise the labour-intensive and costly exercise

of obtaining a satisfactory conclusion to an unbiased

and ranked series of machinability results. ere are

a range of techniques that can be utilised to assess

whether the cutting data inputs, namely: feeds, speeds,

D

OC

’s, etc., will result in the correct inputs to obtain

an extended tool life, or an improvement in the ma-

chined surface texture from the testing program. One

such method is termed the ‘Latin square’ – which as-

sesses the signicance of the test data and its interac-

Chapter

Figure 148. Graphical results obtained from the accelerated machinability test, illustrating how ank wear and

surface texture degrades, with the number of facing-o passes

.

Machinability and Surface Integrity

tions. For a practical machinability trial employing a

‘Latin square’ , it uses a two-way ANOVA

13

table, with a

limited amount of ‘degrees of freedom’ , typically: fee

-

drate, cutting speed, D

OC

, plus surface nish – these

parameters can be changed/modied to suit the ‘pro-

gramme of machining’ in hand. By using a very lim-

ited group of cutting trials, a two-way ANOVA table

can be constructed and their respective ‘F-ratio’ for

each interaction can be determined. is calculated ‘F-

ratio’ should be greater than the 5% ‘condence limit’

of the statistical distribution to be signicant. If the F-

ratio falls below –5% (i.e. for the calculated F-ratio),

then the interactions are not signicant, which ne-

cessitates increasing the ‘factor strength’ (e.g. increas-

ing the: cutting speed, feedrate, etc.), to generate data

which is >5% condence limit – as shown by the ‘feed-

back loop’ in Fig. 149, or alternatively, using a dierent

factor. By such means, ANOVA tests for signicance of

machining data, ensures that the processing parameters

utilised for the prospective machinability trial are both

valid and the correct ones to use in the proposed ma-

chining programme.

13 ‘Analysis of variance’ (ANOVA), or as it should be more ap-

propriately termed the ‘analysis of variation about the means’ ,

consists of portioning the total variation present in a data set

into ‘components’. Each ‘component’ is attributed to an iden-

tiable cause, or source of variation; in addition, one ‘com-

ponent’ represents the variation due to uncontrolled factors

and random errors associated with the response measure-

ments.Specically, if the data set consists of ‘n’ measurements

‘y

1

.…,y

n

’ and their mean is denoted by: ‘y ’ , the total varia-

tion about the mean is embodied in the ‘sum of squared de-

viations’ , as following diagram depicts, for the ‘partitioning

scheme’ for ANOVA:

Total Sum of Squares about the mean:

n

�

i=

(y

−

¯

y)

↓ ↓ ↓ ↓ ↓

Sum of

squares

– due to

Source1

Sum of

squares

– due to

Source2

Sum of

squares

– due to

Source3

Sum of

squares

– due to

Source4

Error, or

residual

Sum of

Squares

e technique of analysis of variance decomposes this total

‘sum of squares’ into the parts shown above, for a case in

which four identiable sources of variation are present – in

addition to the ‘error component’. e number of identiable

causes of variation and the formulae for the ‘component sums

of squares’ are intrinsically connected to the specic experi-

mental design utilised, in the data collection and to the statis-

tical model deemed appropriate for this analysis.

Rather than spending considerable time, eort

and indeed exorbitant expense, on a large and com-

plex machining testing programme, which more oen

than not, produces numerous machined components

that are almost indistinguishable from each other. It

might be more prudent, to conduct a ‘condensed’ series

of trials, based upon a rigorous statistically-designed

methodology. erefore, experiments based on the so-

called ‘orthogonal arrays’ can be benecially engaged

in this regard. Many applied researchers and engineers

have utilised a range of factorial-designed experi-

ments, typied by the ‘Taguchi-approach’.

e main problem with these ‘arrays’ is that in many

situations the large number of ‘interactions’ (i.e. fac-

tors) have been shown to interfere with the overall re-

sults – introducing ‘secondary eects’ , which will not

have been anticipated for, when the original strategic

programme was devised

14

. Such spurious data, could

seriously aect future machining recommendations

and inuence the outcome in a negative manner. e

‘interaction problem’ can have these aects consider-

ably reduced by incorporating a more ‘truncated-ap-

proach’ to the experimental design strategy for the

machinability trials, rather than using a ‘full’ Taguchi

orthogonal array (Fig. 150). For example, if all of the

experiments are conducted in for example one of ‘stan-

dard’ the Taguchi L

8

(2

7

) orthogonal array, depicted in

Fig. 150, then the ‘total outcomes’ (i.e. components

machined), would be: 2

7

= 128 × 8 = 1,024 individual

components machined. Here, in the Taguchi orthogo-

nal array seven factors have been employed and with

the vast amount of components produced from such a

long-running and very costly machining programme,

many of the pertinent details will be lost on those en-

gineers/researchers attempting to de-code the vast as-

sortment of machinability data collated. However, it

is possible to utilise a much simpler-approach to the

overall massive data-collection and analysis problem,

yet still providing statistical signicance, this can be

achieved by adopting a ‘Fractional factorial-designed

experiment’. Here, instead of the virtually ‘mindless

task’ of producing 1,024 almost identical components,

14 ‘Orthogonal array factors’ – when utilising a ‘full’ Taguchi-

designed orthogonal array for a complete picture of all of the

interactions, then it has been shown (Shainin, 1985 – see refer-

ences), that if many factors are employed (i.e. normally >5),

this results in unwanted ‘secondary eects’ which cannot be

accounted for, leading to spurious results from any machin-

ability trials.

Chapter

by using a ‘Fractional factorial-designed experiment’

with an identical matrix to that given in Fig. 150,

only 8 components are produced! is testing regime

is both signicantly quicker and much less costly to

perform, obtaining a ‘snap-shot’ of the overall ma-

chinability problem, but because considerably less tes-

tpieces are produced, the ‘interaction-problem’ and its

‘secondary eects’ are not an issue, even when seven

factors are utilised. Obviously, this machinability data

has to be collated and investigated in a disciplined and

controlled fashion. One tried-and-tested method of

establishing an unbiased and ranked interpretation of

these results, is to use the much misunderstood and

maligned technique of ‘Value Analysis’

15

(VA). is VA

when used to show trends in competitive functions

15 ‘Value Engineering and Analysis’ (VE/VA), with VE being

principally concerned with an overall improvement of design-

based details on engineering components, while a more lim-

ited form of this technique is termed VA – being particularly

relevant for detailed interpretation of recorded data from ex-

perimentation. Here, in this case, from the wide-ranging and

oen seemingly unrelated output of machinability trials.

Figure 149. Flow chart indicating the desigh philosophy for unbiased and ranked machinability trials.

Machinability and Surface Integrity

Figure 150. A fractional factorial-designed experiment, based upon a Taguchi L

8

(2

7

) – orthogonal array.

Chapter

and operations, can be successfully utilised from the

comparisons of cutting uids, through to complex and

dicult-to-machine aerospace machinability trials. If

a more sophisticated technique is required, then it is

also possible to utilise ‘Quality Function Deployment’

16

(QFD), to obtain a complete picture of the outcomes

from machining trials. QFD is oen used by indus-

try as a means for its ‘Continuous-improvement pro-

grammes’

17

. Here for ‘simplicity’s-sake’ , the more basic

and somewhat less complex VA tabulated data-colla-

tion approach, will be briey reviewed.

e application of VA to a series of collated and

compiled massed-data is not new. In fact, it was

widely-used during the 1960’s, but fell into disfavour,

partly because its function and operation were oen

not well-dened – this being exacerbated by poor im-

plementation of its recommendations. However, VA

techniques are useful, allowing one to interpret data

trends both quickly and objectively – without undue

bias – at a glance of a spreadsheet. Not only can signi-

cant trends be readily seen, but the spreadsheet shown

in Fig. 151 – shows a typical machinability data for P/

M compacts drilled by two diering drill-point geom-

etries. By using the spreadsheet, not only can overall

trends be readily seen, it also can depict sub-set trends

as well, giving a complete picture (i.e. globally) of the

important criteria in assessing machining data. As a

simple ranking system is used, considerable objectiv-

ity can be gained and with little undue inuence – bias,

aecting the outcome from these tabulated results. In

employing the ranking of the results, it is normal prac-

tice to decrement down and if two values are ranked

identically, then they are given the same rankings, fol-

lowed by the next lower ranking, being two numbers

lower, as following example shows:

16 ‘Quality Function Deployment’ (QFD), is a general term that

means the: ‘Deployment of quality through deployment of qual-

ity functions’ (Akao, 1988). It is oen known as the ‘House of

Quality’ , because the tabulated graphical representation looks

similar to that of a house – when all the interacting factors

for subsequent analysis have been included on the chart. is

QFD technique, is a wide-ranging philosophy for the com-

plete analysis of both simple and intricate designs and can be

successfully exploited for machinability trials.

17 ‘Continuous-improvement programmes’ , can be dened as

an: ‘Operational philosophy that makes the best use of resources

in order to increase product, or service quality and result in

more eective satisfaction of customers’ (Swanson, 1995).

For example, in Fig. 151 – for the values shown in

column two (i.e. le-hand side: Jobber drill, rust

Force 0.254 N):

Compact type: 1 2 3 4 5 6 7 8

Ranking: 6 8 5 1 5 7 3 2

NB Here, two 5’s were ranked, meaning that the next

decremented value would rank as 3. Hence, in this case

the Low compaction Compact type No. 2 this was best

and Low compaction No. 4 worst – as jobber drilled.

is ‘truncated approach’ the elementary and easily

comprehended VA tabulation (Fig. 151) , enables non-

specialists, together with knowlegdible experimenter,

to recognize the inuence various machining param-

eters have on the potential performance of the trials

undertaken. By judicious use, the VA technique in

conjunction with a strictly controlled and limited ma-

chining strategy – based upon some form of ‘orthogo-

nal array’ , in combination with the ‘strength’ (i.e >5%

‘F-ratio’) of parameters by ANOVA, this will enable a

researcher to conduct a speedy, compact, realistic, yet

meaningful machinability assessment.

7.2 Machined Roundness

Roundness is a condition of a ‘surface of revolution’ ,

which can take the form of a: cylinder, cone, or sphere,

where all the peripheral data points (i.e. measure-

ments) intersect. In reality, the radius of say, a nomi-

nally round workpiece tends to deviate – from the

‘true circle’ – around the periphery of the part, making

these variations the theme to subjective interpretation

of the measured results. In fact, in the past, the sim-

plistic technique for the assessment of roundness was

usually measuring three diameters on a workpiece, to

determine the diametrical variations, then ‘averaging’

to give its overall dimensional size. Moreover, for vari-

ations in a workpiece’s radius about an axis of rotation,

this was oen found by positioning the part between a

‘bench-’ , or sine-centres’ – the latter equipment is em

-

ployed for turned tapered features, then rotating and

monitoring it with dial gauges both at and along its

length. In the past, this rather supercial metrologi-

cal workpiece assessment was supposed to inform the

inspector as to its potential in-service performance.

If some radial variations occurred, this geometrical

Machinability and Surface Integrity

Figure 151. Value analysis – tabulation of the performance of two drilling

points and a typical range of drilling data, when machining powder metal-

lurgy compacts

.

Chapter