Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_5 pdf

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (921.78 KB, 9 trang )

perfectly matched, allowing either a partial arc,

or circular feature to be reproduced. If non-syn-

chronised motion occurs, oen termed ‘servo-mis-

match’

41

between these two axes, then an elliptical

prole – usually inclined at an 45° angle occurs,

•

Squareness – when orthogonal (squareness) is not

maintained between the two interpolating axes,

then the net result will look similar to that of a

milled angular elliptical prole shape, which is un-

aected by the selected circular interpolation rota-

tional direction.

Considerably more machine tool-induced factors can

aect a milled circular interpolated prole. ese ‘er-

rors’ can be found, isolated and then reduced by di-

agnostically interrogation by using dynamic artefacts,

such as the ballbar. Ballbars and their associated in-

strumentation can not only nd the sources of error,

they can prioritise their respective magnitudes – to

show where the main ‘error-sources’ occur, then in-

stigate any feed corrections into the CNC controller

to nullify these ‘machine-induced errors’. As a result

of eliminating such ‘error-sources’ , this enables the

milled circular contouring and overall performance to

be appreciably enhanced.

7.5 Machined Surface Texture

Introduction to Surface Texture Parameters

When a designer develops the features for a component

with the requirement to be subsequently machined

utilising a computer-aided design (CAD) system, or

by using a draughting head and its associated draw-

ing board, the designer’s neat lines delineate the de-

sired surface condition, which can be further specied

by the requirement for specic geometric tolerances.

In reality, this designed workpiece surface condition

cannot actually exist, as it results from process-in-

duced surface texture modications. Regardless of the

method of manufacture, an engineering surface must

have some form of ‘topography, or texture’ associated

41 ‘Servo-mismatch’ , can oen be mistaken for a ‘squareness er-

ror’ , but if the contouring interpolation direction is changed,

from G02 (clockwise) to G03 (anti-clockwise) rotation, then

an elliptical prole will ‘mirror-image’ (‘ip‘) to that of the op-

posite prole – which does not occur in ‘squareness errors’.

with it, resulting from a combination of several inter-

related factors, such as the:

•

Inuence of the workpiece material’s microstruc-

ture,

•

Surface generation method which includes the cut-

ting insert’s action, associated actual cutting data

and the eect of cutting uid – if any,

•

Instability may be present during the production

machining process, causing induced chatter, result-

ing from poor loop-stiness between the machine-

tooling-workpiece system and chosen cutting data,

•

Inherent residual stresses within the workpiece

can occur, promoted by internal ‘stress patterns’

42

–

causing latent deformations in the machined com-

ponent.

From the restrictions resulting from a component’s

manufacture, a designer must select a functional sur-

face condition that will suit the operational constraints

for either a ‘rough’ , or ‘smooth’ workpiece surface. is

then raises the question, posed well-over 25 years ago –

which is still a problem today, namely: ‘How smooth is

smooth?’ is question is not as supercial as it might

at rst seem, because unless we can quantify a surface

accurately, we can only hope that it will function cor-

rectly in-service. In fact, a machined surface texture

condition is a complex state, resulting from a combi-

nation of three distinct superimposed topographical

conditions (i.e. as diagrammatically illustrated Fig.

160a), these being:

42 ‘Stress patterns’ , are to be expected in a machined compo-

nent, where: corners, undercuts, large changes in cross-sec-

tions from one adjacent workpiece feature to another, etc.,

produce localised zones of high stress, having the potential

outcome for subsequent component distortion. ‘Modelling’

a component’s geometry using techniques such as: nite ele-

ment analysis (FEA), or employing photo-elastic stress analy-

sis* models or similar simulation techniques, will highlight

these potential regions of stress build-up, allowing a designer

to nullify, or at worst, minimise these potential undesirable

stress regions in the component’s design.

*Photo-elastic stress analysis displays a stress-eld, normally

a duplicate of the part geometry made from a thin two-dimen-

sional (planar) nematic liquid crystal, or more robustly from

a three-dimensional Perspex model, which is then observed

through polarised light source. is polarised condition, will

highlight any high-intensity stress-eld concentrations in the

part , which allows the ‘polarised model’ to be manipulated

by applying either an un-axial tension, or perhaps a bi-axial

bending external stress to this model, showing dynamically its

potential stress behaviour during its intended in-service con-

dition.

Machinability and Surface Integrity

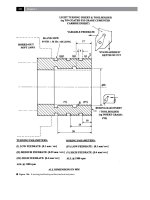

Figure 160. Surface texture comprises of: ‘long-’, ‘medium-’ and ‘short-components’, together with the

‘direction of the dominant pattern’ – superimposed upon each other. [Courtesy of Taylor Hobson]

.

Chapter

1. Roughness – comprising of surface irregularities

occurring due to the mechanism of the machining

production process and its associated cutting insert

geometry,

2. Waviness – that surface texture element upon

which roughness is superimposed, created by fac-

tors such as the: machine tool, or workpiece deec-

tions, vibrations and chatter, material strain and

other extraneous eects,

3. Prole – represents the overall shape of the ma-

chined surface – ignoring any roughness and wavi-

ness variations present, being the result of perhaps

the long-frequency machine tool slideway errors.

e above surface topography distinctions tend to be

qualitative – not expressible as a number – yet have

considerable practical importance, being an estab-

lished procedure that is functionally sound. e com-

bination of roughness and waviness surface texture

components, plus the surface’s associated ‘Lay’

43

are

shown in Fig. 160a. e ‘Prole’ is not depicted, as it

is a long-frequency component and at best, only its

partial aect would be present here, on this diagram.

e ‘Lay’ of a surface tends to be either: anisotropic,

or isotropic

44

in nature on a machined surface topog-

raphy. When attempting to characterise the potential

functional performance of a surface, if an anisotropic

‘lay-condition’ occurs, then its presence becomes of

vital importance. If the surface texture instrument’s

stylus direction of the trace’s motion over the assessed

topography is not taken into account, then totally mis-

representative readings result for an anisotropic sur-

face condition occur – as depicted in Fig. 160b. is

is not the case for an isotropic surface topography, as

relatively uniform set of results will be present, regard-

less of the stylus trace direction across the surface (i.e.

43 ‘Lay’ , can simply be dened as: e direction of the dominant

pattern’ (Dagnall, 1998).

44 ‘Anisotropic, or isotropic surfaces, either condition can be in-

dividually represented on all machined surfaces. Anisotropy,

refers to a surface topography having directional properties,

that is a dened ‘Lay’ , being represented by machined feed-

marks (e.g. turned, shaped, planed surfaces, etc.). Conversely,

an isotropic surface is devoid of a predominant ‘Lay’ direc-

tion, invariably having identical surface topography charac-

teristics in all directions (e.g. shot-peening/-blasting and, to a

lesser extent a multi-directional surface-milling, or a radially-

ground surface, etc.).

see Fig. 161a – for an indication of the various clas-

sications for ‘Lay’).

Returning once more to Fig. 160b, as the stylus

trace obliquity changes from trace ‘A’ , inclining to

-

ward trace ‘E’ , the surface topography when at ‘E’ has

now become at, giving a totally false impression of

the true nature of the actual surface condition. If this

machined workpiece was to be used in a critical and

highly-stressed in-service environment, then the user

would have a false sense of the component’s potential

fatigue

45

characteristics, potentially resulting in ei-

ther premature failure, or at worst, catastrophic fail-

ure conditions. In Fig. 162, the numerical data (ISO

1302:2001), has been developed to establish and de-

ne relative roughness grades for typical production

processes. However, some caution should be taken

when utilising these values for control of the surface

condition, because they can misrepresent the actual

state of the surface topography, being based solely on a

derived numerical value for height. What is more, the

‘N-number’ has been used to ascertain the arithmetic

roughness ‘Ra’ value – with more being mentioned on

this and other parameters shortly. e actual ‘N-value’

being just one number to cover a spread of potential

‘Ra’ values for that production process. Neverthe-

less, this single numerical value has its merit, in that

it ‘globally-denes’ a roughness value (i.e.‘Ra’) and

its accompanying ‘N-roughness grade’ , which can be

used by a designer to specify in particular a desired

surface condition, this being correlated to a specic

production process. e spread of the roughness for a

specic production process has been established from

experimental data over the years – covering the maxi-

mum expected ‘variance’

46

– which can be modied

45 ‘Fatigue’ , can be dened as: ‘e process of repeated load, or

strain application to a specimen, or component’ (Schaer, et

al., 1999). Hence, any engineering component subjected to

repeated loading over a prescribed time-base, will normally

undergo either partial, or complete fatigue.

46 ‘Variance’ , is a statistical term this being based upon the

standard deviation, which is normally denoted by the Greek

symbol ‘σ’. us, variance can be dened as: ‘e mean of the

squares of the standard deviation’ (Bajpai, et al., 1979).

us, σ = √Variance, or more specically for production op-

erations:

�

s

n

n

j=

x

j

¯

x

*s = the standard deviation of a sample from a production

batch run.

Machinability and Surface Integrity

depending upon whether a ne, medium, or coarse

surface texture is obligatory. Due to the variability in

any production process being one of a ‘stochastic out-

put’

47

, such surface texture values do not reect the

likely in-service performance of the part. Neither the

surface topography, nor its associated integrity has

been quantied by assigning to a surface representa-

tive numerical parameters. In many instances, ‘surface

engineering’

48

is utilised to enhance specic compo-

nent in-service condition.

It was mentioned above that in many in-service

engineering applications the accompanying surface

texture is closely allied to its functional performance,

predominantly when one, or more surfaces are in mo-

tion with respect to an adjacent surface. is close

proximity between two mating surfaces, suggests that

the smoother the surface the better, but this is not nec-

essarily true if the surfaces in question are required to

maintain an ecient lubrication lm between them.

e apparent roughness of one of these surfaces with

respect to the other, enables it to retain a ‘holding-

lm’ in its associated topographical ‘valleys’

49

. While

another critical factor that might limit the designer’s

choice of the smoothness of an engineering surface’s

selection, is related to its production cost (i.e. see

Fig. 161b). erefore, if the designer requires a very

smooth machined surface, it should be recognised that

its manufacturing time is considerably longer – so its

respective cost will be greater to that of a rough sur-

face, this being exacerbated by a very close dimen-

sional tolerance requirement.

47 ‘Stochastic processes’ , are dened as: ‘A process which has a

measurable output and operating under a stable set of condi-

tions which causes the output to vary about a central value in a

predictable manner’ (Stout, 1985).

48 ‘Surface engineering’ , is applying suitable discrete technolo-

gies to create surface lms (e.g. 10 to 100 nm thick), or by ma-

nipulating the surface atomic layers (e.g. 2 to 10 atomic layers,

approximately 0.5 to 3 nm), to enhance the ‘engineered’ sur-

face condition (i.e. Source: Vickerman, 2000).

49 ‘Surfaces’ , are recognised to have topographical features that

mimic the natural world. So a regular/irregular engineering

surface can exhibit both peaks and valleys, not unlike moun-

tainous terrain.

.. Parameters for Machined

Surface Evaluation

In order that a machined workpiece’s surface texture

can be determined using stylus-based (two-dimen-

sional) instrumentation, three characteristic lengths

are associated with this surface’s prole (i.e. see

Fig. 163a), these are:

1. Sampling length

50

– is determined from: the length

in the direction of the X-axis used for identifying

the irregularities that characterise the prole under

evaluation. erefore, virtually all surface de-

scriptors (i.e. parameters) necessitate evaluation

over the sampling length. Reliability of the data

is enhanced by taking an average of the sampling

lengths as depicted by the evaluation length shown

in Fig. 162a. Most of today’s stylus-based surface

texture instruments undertake this calculation au-

tomatically,

2. Sampling length – can be established as: the to-

tal length in the X-axis used for the assessment of

the prole under evaluation. From Fig. 163a, this

length may include several sampling lengths – typi-

cally ve – being the normal practice in evaluating

roughness and waviness proles. e evaluation

length measurement is the sum of the individual

sampling lengths (i.e. it is common practice to em-

ploy a 0.8 mm sampling length for most surface

texture assessments),

3.

Traverse length – can be dened as: the total

length of the surface traversed by the stylus in mak-

ing a measurement. e traverse length will nor-

mally be longer than the evaluation length (i.e. see

Fig. 163a), this is due to the necessity of allowing

‘run-up’ and ‘over-travel’ at each end of the evalua-

tion length. ese additional distances ensure that

any mechanical and electrical transients, together

lter edge eects are excluded from the measure-

ment.

50 ‘Sampling length’ , is oen termed ‘Meter cut-o ’ , or simply

the ‘cut-o ’ length and its units are millimetres. e most

common cut-os are: 0.25, 0.8, 2.5, 8.0, 25.0 mm. e 0.8 mm

sampling length will cover most machining production pro-

cesses. In any surface texture evaluation, it is essential that the

cut-o is made known to the Inspector/Metrologist reviewing

this surface topographical data.

Chapter

e number of two-dimensional surface prole pa-

rameters that have been developed over the years for

just the stylus-based instruments – discounting the

three-dimensional contact and non-contact varieties,

has created a situation where many users simply do

not understand, nor indeed comprehend the intrinsic

dierences between them! A term was coined some

years ago to show exasperation by many metrolo-

gists’ with this ever-increasing development of such

parameters. Many researchers and companies were

totally disenchanted with their confunsion and plight,

so they simply called the predicament: ‘parameter-

rash’. However, here we need not concern ourselves

with this ‘vast expanse of surface descriptors’ , as only

a few of the well-established parameters and discuss

just the most widely-utilised ones. It is worth making

Figure 161. ‘Lay’ indicated on drawings, plus the relative cost of manufacture for dierent production processes.

Machinability and Surface Integrity

Figure 162. Anticipated process ‘roughness’ and their respective grades. [Source: ISO 1302, 2001].

Chapter

Figure 163. Surface texture data-capture, with techniques for the derivation of the arithmetic roughness parameter: Ra.

Machinability and Surface Integrity

the point, that all of these two-dimensional surface pa-

rameters can be classied into three distinct groupings

and just some of these parameters are:

1. Amplitude parameters (Ra, Rq, Wa, Wq, Pa, Pq)

51

– with Ra

52

being universally recognised for the

‘international’ parameter’ for roughness. It is: ‘e

arithmetic mean of the absolute departures of the

roughness prole from the mean line’ (i.e. see Fig.

163b and c). It can be expressed as follows:

Ra lr

l r

zx dx

(units of m)

NB e Ra parameter is oen utilised in appli-

cations to monitor a production process, where a

gradual change in the surface nish can be antici-

pated, making it seem to be ‘ideal’ for any form of

machinability trials, but some caution is required

here, as will be seen shortly in further discussion

concerning this ‘surface descriptor’. By way of com-

parison, another previously used amplitude param-

eter is given in Appendix 10 and is the ‘R

Z

(JIS)’ (i.e.

10-point height) parameter.

Other useful parameters of the assessed prole, to be

shortly discussed in more detail, include: ‘Skewness’

(Rsk, Wsk, Psk), which is oen utilised in association

with ‘Kurtosis’ (Rku, Wku, Pku), producing the so-

called: ‘Manufacturing Process Envelopes’ – as a means

of ‘mapping’ and correlating machined surface topog-

raphies.

2. Spacing parameters (Rsm, Wsm, Psm) – can be de-

ned as: ‘e mean spacing between prole peaks at

the mean line, measured within the sampling length’

(i.e. depicted along a machined cusp – at diering

51 e designation of the letters follows the logic that the pa-

rameter symbol’s rst capital letter denotes the type of prole

under evaluation. For example, the: Ra* – calculated from the

roughness prole; Wa – derives its origin from the waviness

prole; with the latter in this logical sequence, namely the Pa

– being derived from the primary prole. Here, in this discus-

sion and for simplicity, only the rst term in the series – e.g.

‘Ra’ notation – will be used.

*Ra is today shown in the International Standard (i.e. ISO

4287: 1997) as being denoted in italics, while in the past, it was

usually shown as follows: ‘R

a

’ , but even now, many companies

still use this particular notation.

52 Historically, the classication of the relative roughness of sur-

faces was initially developed in England and was then termed:

‘Centre Line Average’ (CLA), while in the USA its equivalent

term was the ‘Arithmetic Average’ (AA).

feedrates in Fig. 169a and b). It can be expressed in

the following manner:

Rsm n

i=n

i=

si

XS+ XS+XS + XSn

n

Where:

n = number of peak spacings.

NB e Rsm parameter needs both height and spac-

ing discrimination and, if not specied the default

height bias utilised is 10% of: Rz, Wz, or Pz, – where

these are the ‘Maximum height of prole’. As can be

seen from the ‘idealised’ machined surface topog-

raphy given in Fig. 169a and b, the spacing param-

eters are particularly useful in determining the feed

marks. Moreover, the Rsm parameter relates very

closely to that of the actual programmed feed rev

–1

of

either the cutter, or workpiece – depending on which

production process was selected. See also, Appendix

10 for a graphical representation of the previously

utilised ‘High Spot Count’ (HSC) parameter.

3. Hybrid parameters (Rmr, Wmr, Pmr, R∆q, W∆q,

P∆q, Rpk, Rk, Rvk) – each of these ‘hybrids’ will

now be briey mentioned. Rmr, or its alternative

notation Mr is the ‘Material ratio curve’ , which can

be dened as: ‘e length of the bearing surface (ex-

pressed as a percentage of the evaluation length ‘L’) at

a depth ‘p’ below the highest peak (i.e. see Fig. 165).

–

Rmr:

It is oen known as the

‘Abbott-Firestone curve’ ,

the mathematics of this Rmr-curve can be ex-

pressed in the following manner:

Rmr

b+b+b=B +bn

n

n

i=n

i=

bi

NB is ‘Material ratio curve’ represents the pro-

le as a function of level. More specically, by plot-

ting the bearing ratio at a range of depths in the

prole trace, the manner by which the bearing ratio

changes with depth, provides a method of charac-

terising diering shapes present on the prole (i.e.

see Fig. 165 and Appendix 10).

–

R∆q:

e

R∆q parameter, can be dened as: ‘e root

mean square (rms) slope of the prole within the

sampling length’ (i.e. see how its angle changes at

diering machining feedrate conditions shown

in Fig. 169b and c), it can be mathematically ex-

pressed as follows:

Chapter

R q

lr

l r

θx

¯

θ

dx

Where:

¯

θ lr

l r

θxdx

θ = slope of the prole at any given point.

•

Rpk, Rk, Rvk:

ese parameters (i.e. see Appendix 10 for graphi

-

cal representations of the parameters), were origi-

nally designed for the control of potential wear in

automotive cylinder bores in volume production

by the manufacturing industry. Today, Rpk, Rk and

Rvk are employed across a much more diverse-eld

by a range of industries. Such hybrid parameters

are an attempt to explain – in numerical terms, the

respective form taken from the prole’s trace of the

‘material ratio curve’ (Rmr), hence:

–

Rpk parameter – is the ‘reduced peak height’ , il-

lustrating that the top portion of a bearing sur-

face will be quickly worn-away when for exam-

ple, an engine initially begins to run,

–

Rk parameter – is known as the ‘kernal rough-

ness depth’ , therefore the long-term running –

‘steady-state wear’ of this surface will inuence

for example, the performance and life of the au-

tomotive cylinder(s),

–

Rvk parameter – is the ‘trough depth’ this in-

dicates that the surface topography has an oil-

retaining capability, specically via the ‘trough

depths’ which have been purposely ‘cross-

honed’

53

into the bore’s surface.

Arithmetic roughness parameter (Ra)

Although the Ra ‘amplitude parameter’ has been

widely quoted ‘Internationally’ , there are a few provi

-

53 ‘Cross-honing’ , uses either: (ne) Abrasives/CBN/Diamond –

‘stones’ , that are tted into a ‘honing head’ which then rotates

and oscillates within a hole, or an engine’s bore. e critical

parameters are the rotational speed (Vr) oscillation speed

(Vo), the length and position of the honing stroke, the hon-

ing stick pressure (Vc). e inclination angle of the cross-hon-

ing action, is a product of the up-/down-ward head motion

(Vo) and the rotational speed for the head (Vo). is complex

action of rotating and linear motion, generates the desired

cross-honed ‘Lay-pattern’ within the bore – for improved oil

retention.

sos, or conditions that must be met, if it is to be utilised

satisfactorily, these are:

•

e Ra value over one sampling length represents

the average roughness. e eect of a spurious non-

typical peak, or valley within the prole’s trace be-

ing ‘averaged-out’ so will have only a small inu-

ence on the Ra value obtained;

•

e evaluation length contains several sampling

lengths (Fig.163a), this ensures that the Ra value is

representative of the machined surface under test;

•

An Ra value alone is meaningless, unless quoted

with its associated metre cut-o (λc) length. Repeat-

ability of the Ra value will only occur at an identi-

cal length of metre cut-o;

•

If a dominant surface texture pattern occurs (Lay), then

the Ra readings are taken at 90° to this direction;

•

at Ra does not provide information as to the

shape of either the prole, or its surface irregulari-

ties. Dierent production processes generate diverse

surface nishes, for this reason its is usual to quote

both the anticipated Ra numerical value along with

the actual manufacturing process;

•

Ra oers no distinction between peaks and valleys

on the surface trace.

e most confusing argument concerning the use of

an Ra value alone, is that its numerical value is not

only meaningless, but it can have catastrophic conse-

quences if interpreted incorrectly. ese opinions can

be substantiated by close observation of Fig. 164a,

where an identical numerical Ra value produces

widely divergent surface topographies. In addition, if a

designer’s engineering application called for a ‘bearing

surface’ (Fig. 164ai), rather than a ‘locking surface’ (Fig.

164aiii), then the numerical value of 4.2

µm in isola-

tion, becomes pointless, as it tells the designer nothing

about the ‘functional’ surface topography. is prob-

lem is exacerbated when the wrong surface topography

is selected for a specic engineering application. For ex-

ample, a ‘locking surface’ applied to a bearing industrial

application in a harsh environment, can be expected to

catastrophically fail aer very little in-service time.

Skewness (Rsk, Wsk, Psk) and Kurtosis

(Rku, Wku, Pku) Parameters

ese surface descriptors of ‘skewness’ and ‘kurtosis’

are oen derided as simply ‘statistical’ amplitude pa-

rameters, that can introduce spurious results and as a

consequence, having little use in engineering applica-

tions. However, when used in the correct context, they

can provide a valuable insight into the overall shape of

Machinability and Surface Integrity