Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_7 ppt

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (1.8 MB, 9 trang )

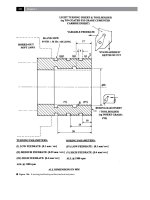

Figure 169. How the feedrate inuences the machined

cusp/surface roughness value ‘Sm’ and its aect on the wavi-

ness parameter ‘Δq’, plus surface topography of actual longi-

. tudinal CNC turned P/M ferrous compacts – cut with diering

nose radii. [Courtesy of Joel (UK) Ltd.]

Machinability and Surface Integrity

the considerably larger eective tool nose radius, act-

ing like a ‘wiper-blade’ blending-out and obliterating

the surface’s cusps. is technique of utilising a large

tool nose geometry has traditionally been used by pre-

cision turners to improve the overall surface nish.

.. Manufacturing Process

Envelopes

e principal features of manufacturing process en-

velopes and indeed, for many amplitude distribution

curves is that they can be approximated by the so-

called ‘beta-function’ – ‘β’ (Fig. 170a). Here, the func-

tion has two parameters that are independent of one

another enabling them to be used as a means of sur-

face characterisation. e notation ‘a’ is the allocated

weighting for the prole ordinates measured from the

lowest valley and above, with notation ‘b’ being given

to weighting the prole from the highest peak down.

Hence, peaks and valleys have accordingly dierent

weights. One of the problems that has arisen from util-

ising this technique for a topographical prole, which

has somewhat discredited them for certain applica-

tions, is how and in what manner can one determine

‘a’ and ‘b’.

e ‘beta-function’ is normally dened within a set

range of: 0→1, being expressed in the following man-

ner:

β(a, b) =

�

z

a−

(a − z)

b−

dz

.

If by changing the range of the ‘beta-function’ equa-

tion above, from: 0→1 to Rp + Rv, or indeed with that

of Rt, then substituting σ (i.e. the standard deviation

of the distribution) with Rq, the beta-function param-

eters ‘a’ and ‘b’ become:

a =

Rv (Rv Rp – Rq

2

/Rt Rq

2

)

b =

Rp (Rv Rp – Rq

2

/Rt Rq

2

).

e fact that any dominant peak, or valley within the

assessment length is only raised to a unit power, in-

fers additional stability over the ‘skewness/kurtosis ap-

proach’. e problem with this ‘beta-function’ method

is in accurately determining ‘sound’ results from the

Rv and Rp, which conrms the diculty that obtain-

ing information from peak/valley measurement and

then deriving valid information is fraught with com-

plications. In Figs. 170: ‘ai’ it is symmetrical; with ‘aii’

being asymmetrical; for their respective ‘beta-func-

tions’ , these relationships are based upon a class of sta

-

tistically-derived ‘Pearson distributions’

59

. In the sym-

metrical case (Fig. 170ai) the skewness equates to zero;

conversely, for an asymmetrical series of results (Fig.

170aii), skewness can be either positively, or negatively

skewed (i.e see Fig. 164bii). Nevertheless, even allow-

ing for these limitations, an example of the groups of

manufacturing process envelopes for a range produc-

tion processes is illustrated in Fig. 170b. Here, the pro-

duction processes can be simplistically classied and

grouped into either a ‘bearing’ , or ‘locking’ surface

topography. e ‘bearing-/locking-groupings’ indicate

that certain production processes can achieve specic

functional surfaces for particular industrial applica-

tions. ese ‘groupings’ (Fig. 170b), also indicate that

the general classications are less distinct than might

otherwise be supposed, as certain processes can be

provide either a ‘locking’ , or a ‘bearing’ surface condi

-

tion – termed ‘intermediate groupings’. Typical of such

an ‘intermediate group’ are the P/M drilled compacts.

One reason for this is that any P/M ‘secondary ma-

chining’ oen utilises twist drills, which may produce

59 ‘Pearson product moment correlation coecient’* – to give

it its full title, is a statistical association utilised when a ‘rela-

tionship’ exists between several quantities and it is a measure

of the extent of this aliation, thus producing its ‘correlation

coecient’ which can then be utilised.

*For example, having a sample of pairs of observations ‘x’ and

‘y’ , the value ‘r’ of this ‘Pearson coecient’ , is given by the

‘generalised formula’ , below:

r = Σ(x – x ) (y – y) /√ Σ(x – x)

2

Σ(y – y)

2

(Bajpai, et al., 1979):

e calculated ‘Pearson coecient’ should lie either close

to –1, or +1. If the calculated value is close to –1 then the

‘straight-line trend’ is in a downward direction, conversely, if

the calculated value is close to +1 then the ‘straight-line trend’

direction is upward. If the value is close to zero (0), then no

correlation exists, so the pairing of the data is disparate and

cannot be utilised. With calculated data that is reasonably

close to either –1, or +1, a ‘regression line’ (i.e. using linear

regression) can be calculated based upon the general straight-

line formula:

Y = a + bX

Where a ‘regression line of Y on X’ for the two constants ‘a’ and

‘b’ respectively are:

b = nΣxy – (Σx)(Σy)/n(Σx

2

) – (Σx)

2

a = Σy – bΣx/n

Where a ‘regression line of X on Y’ for the two constants ‘a’ and

‘b’ respectively are:

b = nΣxy – (Σx)(Σy)/n(Σy

2

) – (Σy)

2

a = Σx – bΣy/n

NB e ‘regression line’ being the equivalent of the ‘least

squares line’ , allows data on each axes to be compared – with

some degree of condence.(Wild, et al.,1995)

Chapter

Figure 170. The ‘beta-function’ and typical ‘manufacturing process envelopes’.

Machinability and Surface Integrity

a ‘saw-toothed prole’ to the hole’s surface, along with

pores in the compact that are open to the ‘free-surface’

of the hole. e hole topography may have this ‘saw-

toothed eect’ present, it being a combination of the

drill’s partial lip and margin occurring at the feed rev

–1

periodicity, formed by the drill spiralling-down and

around the hole’s periphery. Hence, the drill’s passage

creates a positive skewness via drilled ‘saw-toothed

cusps’ , while the pores can introduce negative skew

-

ness – creating a potential ‘intermediate group’ to the

manufacturing process envelope groupings.

.. Ternary Manufacturing

Envelopes (TME’s)

In machining operations the dominant factor that in-

uences surface topography has been shown to be the

tool’s feedrate. In Fig. 171, the feedrate, in conjunc-

tion with the principal factors such as surface texture

(Ra) and roundness (i.e least squares circle – LSC), are

utilised to dene the limits for these ‘Ternary manu-

facturing envelopes’ (TME’s). By using such diverse

factors as: surface texture, roundness and processing

parameters (feedrate), for the major axes on the ter-

nary graph, enables the surface to be characterised in

a unique manner. Such TME’s dier quite consider-

ably from the more usual and restricted ‘manufactur-

ing process envelopes’ alluded to in the previous section

– the skewness and kurtosis axes of the manufacturing

envelopes, might otherwise mask crucial information.

e ‘TME approach’ gives a psuedo three-dimensional

representation on its ternary axes, which can be ex-

ploited to illustrate how the inuence of changing a

parameter – such as feedrate – modies the relation-

ship of the associated surface texture and roundness

values for the nal machined result.

As an example of the eectiveness of this TME ap-

proach to the complex problem of machining data

analysis, Fig. 171 has been drawn from an actual

machinability trial. If one observes this TME graph

closely for a pre-selected range of turning and boring

processes, indicated in Fig. 171, with specic reference

here, to turning operations – by way of illustrating

the TME’s expediency. e TME shows how – for the

turning operations – at low feedrate (0.10 mm rev

–1

)

the surface texture is closely conned to a relatively

small spread of values – nominally around 0.5-1.5 µm

Ra, whereas its associated roundness lies between

approximately 5 and 50 µm

LSC. As the feedrate in-

creased in an arithmetic progression to 0.25 mm rev

–1

,

the range of the surface texture bandwidth propor-

tionally expanded to 1.5 at approximately 5-6.5 µm

Ra, with a corresponding roundness ranging from 8 to

48 µm

LSC, giving a proportional bandwidth of 1.6. As

the feedrate was raised even higher, to 0.40 mm rev

–1

,

it was not surprising to note that this also produced

increases in both the surface texture and its propor-

tional bandwidth, with similar values with respect to

its roundness. ese ‘machinability and metrology

trends’ allow examination of both the bandwidth vari-

ability and the aect of dierent feedrates on other

disparate factors – such as its machined roundness.

Similar trends occurred for the boring operation,

but here only two feedrates were employed, by applica-

tion of this analysis technique via the ‘TME-approach’

to a concise machinability trial, complex analysis of

the TME is possible. e pseudo three-dimensional

graph, oers perhaps an unusual insight into the mul-

tifaceted inter-relationships that exist aer workpiece

machining. e TME shows that simply examining

one metrological parameter in isolation to those that

could aect it, may mask vitally important relation-

ships and trends that would otherwise remain unseen.

By careful selection of the parameters for the respec-

tive axes, perhaps based upon the feedrate (i.e. here,

normally situated along the X-axis), allows an appre-

ciation of the whole surface at any instant along the

three graph’s axes.

7.6 Machining Temperatures

Ever since Taylor in 1907, recognised that elevated tool

and workpiece temperatures in metal cutting played

a crucial role in inuencing tool edge wear rates, the

subject has been one of intensive study. Moreover,

that the tool/chip interface temperature has a control-

ling inuence on the rate of crater wear and the fact

that tool life can be drastically curtailed by these in-

duced machining temperatures, as such, the topic has

received considerable research attention. Here, space

will only allow a brief resumé of this complex temper-

ature-induced machining problem.

During metal cutting in particular, there are sev-

eral temperature eects that need to be considered. In

Fig. 51, an orthogonal single-point cutting operation

is schematically illustrated, indicating the distribution

of heat sources within the three deformation zones. In

Chapter

Figure 171. ‘Ternary manufacturing envelopes’ for the production processes of turning and boring,

axes: feedrate, roundness and surface texture

.

Machinability and Surface Integrity

particular, the heat generated in the main ‘body’ within

the cutting region via both the primary and secondary

zones is a result here, of the workpiece’s plastic defor-

mation. Still more intensive heat is generated at the

tool/chip interface – along the rake face, with the ma-

jority of heat being swept away with the chips, while

the remainder of heat is either conducted through the

tool, or conducted/convected into the workpiece. As-

suming that no coolant application is present in the

machining operation, then any heat loss to the ambi-

ent air becomes insignicant. An equation has been

developed that governs the temperature distribution –

via its isothermal gradients – in machining (Fig. 172),

this being an ‘energy-based equation’ as follows:

ρC∂T∂t V T k

T

˙

q

(Source: Tay, et al., 1993).

erefore, in steady-state machining operations, the

transient term will disappear and at the region of the

tool (i.e. insert) only the conduction term remains.

∴ Rate of heat generation (˙q) = σ ˙ε

Where: ‘σ’ was obtained from an emprical function of:

‘ε’ , ‘˙ε’; plus ‘T’.

NB is rate of heat generation only exists within the

primary and secondary deformation zones.

By way of example of how the temperature genera-

tion/distribution occurs in orthogonal cutting, in the

more-easily understood ‘Boothroyd machining model’

(i.e. being in a slightly modied form – by the author),

this workpiece material is in a state of ‘continuous

motion’ during cutting (Fig. 172). If specic points

are selected to show how temperatures occur as they

pass along/through these deformation zones then,

the points: ‘X, Y and Z’ can be considered for special

observation. So, as the workpiece material enters the

cutting region at point ‘X’ , it begins to move toward

the cutting insert. It approaches and passes through

the primary deformation zone where it is heated-up

until it leaves this zone, it is then swept-away by the

formed chip. Equally point ‘Y’ , passes through both

the primary and secondary deformation zones (i.e

see Fig. 51 for these deformation zones) and contin-

ues to heat-up until it leaves the secondary deforma-

tion zone. In both of the above cases, these points (i.e.

namely: X and Y) are cooled as heat is conducted into

the chip’s body (as it exit’s the cut), where it eventually

achieves a uniform temperature right the way through.

Prior to this occurring, the maximum temperature

occurs along the cutting insert’s rake face, some dis-

tance from the actual cutting edge (i.e see Fig. 172).

Conversely point ‘Z’ , which remains attached to the

workpiece, is heated by conduction from the primary

deformation zone and some heat is also conducted

from the secondary deformation zone into the body

of the cutting insert, while the tertiary deformation

zone will also impart some heat into the machined

surface of the workpiece.

Many thermal and thermographical techniques

have been developed over the years to obtain accurate

isothermal temperatures within the: cutting zones:

tool/insert interface plus rake face vicinity; together

with the machined surface region of the workpiece.

Moreover, ‘indirect methods’ have been utilised to

obtain similar thermal historical data from within

these dynamic and harsh environments, but only one

of these techniques will be mentioned in the next sec-

tion.

.. Finite Element Method (FEM)

e popular approach today, to obtaining ‘simulated’

thermal data is by employing the ‘Finite element

method’ (FEM), to calculate temperature distributions

in the vicinity of the cutting regions (Fig. 173). Typical

of this approach and worth mentioning in some de-

tail, was that conducted and described by Tay (1993),

where he experimentally-obtained information re-

garding: velocity, strain and strain-rate distributions,

by utilising a printed-grid and quick-stop technique.

e rate of heat generation within the primary defor-

mation zone was determined from the equation:

(˙q) = σ ˙ε.

From the deformed grid pattern (Fig. 173a), the ac-

tual dimensions of the triangular deformation zone,

as well as the velocity distribution along the tool/chip

interface can be established and analysed. By this FEM

technique, it is possible to determine the shear-strain

rate within the secondary deformation zone at the

tool/chip interface:

(˙γ

int

) has been found to be approximately constant

and equal to: V

c/

δt

2

. e shear strain-rate within the

Chapter

Figure 172. Typical temperature distributions (isotherms) during machining, illustrated across the: chip, insert and work-

piece; at relatively low cutting speed

.

Machinability and Surface Integrity

secondary deformation zone tends to be linear in na-

ture from:

(˙γ

int

) – at the interface, → zero – at the boundary of

the triangular secondary zone.

e frictional stress along the tool/chip interface

can be assumed to be constant along the rst half of

the contact region, then linearly decreasing to zero at

its end. e frictional heat source distribution at this

interface, can be obtained from stress and velocity dis-

tributions at this location.

In Fig. 173a, the basic ‘FEM mesh’ is shown, with

typical temperature distributions obtained from this

being illustrated in Fig. 173b. e accuracy of this

particular example for the ‘Tay-model’ for the total

sum of all heat sources was within 2.6% of actual mea-

sured power consumption (F

c

U). Moreover, the values

of ‘β’ calculated from the temperature distributions

closely-agreed to those obtained some years earlier

by Boothroyd (1963). e FEM approach to machin-

ing data capture and analysis covers these and other

related parameters and clearly indicates the power of

simulation – more will be mentioned on this subject

later in the chapter.

7.7 Tool Wear and Life

Introduction

e working environment for most machining pro-

cesses is extremely harsh, with pressures exerted

onto a minute area of tool tip being of the order of

>1600 MPa, with localised temperatures reaching over

750°C creating a sterile surface at the tool/chip inter-

face, making this an ideal state for a pressure-welding

condition. In attempting to minimise this anity be-

tween the work-hardened chip – oen this plastic de-

formation making the chip >5 times harder than that

of the parent workpiece material, means that there are

several ways of relieving this tool/chip anity. e ob-

vious one is to use a cutting tool material that is in-

ert to the workpiece such as a either a: ceramic, or

mixed-ceramic cutting insert composition, or some-

thing similar, but this may not prove to be satisfactory,

particularly if interrupted cutting conditions are antic-

ipated. In this situation above, perhaps by utilising a

multi-coated cemented carbide insert this may reduce

this ‘adherence-tendency’. Lastly, the correct grade of

‘ood-coolant’ may: lower the interface temperature,

reduce friction here, while somewhat improving the

machined surface texture. When only partial success

is achieved by employing the above tooling strategies,

the last resort may be to adjust the cutting data to en-

hance and provide a ‘less-abusive machining regime’ ,

while simultaneously improving the ‘steady-state’ wear

conditions.

So far, no mention has been made here concern-

ing frictional eects in the cutting process. Friction is

very complex subject which relates not only to: chip

ow-stress and ‘stiction’

60

problems at the chip/tool in-

terface, but concerns the tribological conditions along

this interface. Cutting tool rake and ank faces are

never perfectly smooth, as even when faces and edges

have been either been ground, or super-nished the

abrasive nature of the super-nishing process pro-

duces an abraded surface that approaches the grit size

of the abrasive medium. erefore, to the naked eye

the insert’s surface looks smooth, but at the ‘micron-

level’ of surface magnication (i.e. 1 × 10

–6

m), the cut-

ting insert’s surface has localised ‘high-spots’ , or as

-

perities present. ese asperities signicantly reduce

the contact area produced between the forming chip

and its contact at the interface on the tool’s rake face.

Not only can these asperities considerably decrease the

‘real area of contact’ and as a result increase the coe-

cient of friction here, but the asperities may be either

‘plastic’ , or ‘elastic’ in nature

61

. In Table 11 (i.e. exper-

imental data extracted from: Childs, et al., 2000, con-

cerning surface texture assessment of cutting insert

faces), comparison is made between a small sample of

60 ‘Stiction’ , is sometimes confused with its ‘close alternative’

this being: ‘stick-slip’. ese terms are worth stating, to ex-

plain their respective dierences and have been dened in the

following manner: ‘Stiction’ is: ‘e phenomenon at an inter-

face where the frictional stress is equal to the shear yield stress of

the soer material.’

‘Stick-slip’ is: ‘A jerky motion between sliding members due to

the formation and destruction of junctions.’ (Kalpakjian, 1984)

61 ‘Plastic asperities – on a plastic chip’ , these are ‘high-spots’

that will sink into the chip and how they achieve this action,

does not depend on local conditions at interface contact, but

on the bulk plastic ow eld. Specically, the lower the hydro-

static stress in the bulk ow eld, the less eort is required for

these asperities to sink.‘

Asperities – on an elastic foundation’ , this situation is ex-

tremely complex phenomena and put simply, in conditions of

low contact stresses, the chip beneath these asperities is elas-

tic. (Childs, et al., 2000)

Chapter

cutting insert surface conditions, clearly illustrating

that even when ‘super-nishing’

62

an insert’s face it still

has asperities present.

.. Tool Wear

Introduction

On a single-point turning tool’s cutting insert, the

main regions of wear are normally conned to the:

rake face; ank; trailing clearance face; together with

62 ‘Super-nishing’ , is based on the phenomenon that a lubricant

of a given viscosity* will establish and maintain a separating

lm between two mating surfaces, if their roughness does not

exceed a specic value and, if certain critical pressure – keep-

ing them apart – is not exceeded. us, as minute peaks occur

on the cutting insert’s surface, they are then cut away by the

abrasive (e.g. minute diamond abrasive in a lubricant – oil –

suspension) this being applied with a controlled pressure –

until a required level of smoothness has been achieved.

NB e maximum stock removed from the insert will be ap-

proximately 50 µm.(Degarmo et al., 2003)

*Viscosity relates specically to oils, which will vary with

temperature. Dierent oils vary by dissimilar amounts for the

same temperature, this is why the ‘viscosity index’ (VI) has

been developed.

the actual nose radius (Fig. 174). Likewise, the type

of wear pattern provides important information as to

the eectiveness of the overall machining operation.

Considerable time and eort has been spent by both

researchers and tooling companies, ensuring that tool

wear mechanisms and their respective classications

for specic machining operations are understood. So,

by knowing the anticipated wear behaviour for a cut-

ting insert for a specic machining operation, this al-

lows the user to optimise productivity by ensuring that

the ‘ideal’ tool grade and its associated geometry, will

produce the desired machining conditions with the

correct type of cut for the chosen workpiece materi-

al’s composition. A range of factors can inuence tool

wear when component machining, these are: material

removal rate; ecient chip control; machining eco-

nomics, precision and accuracy demanded; plus the

machined surface texture requirements.

If one magnies then inspects the wear pattern on

a worn cutting edge, then it is reasonably straightfor-

ward to establish both the cause and remedy for the

indicated type of wear (i.e see Appendix 11), this will

allow subsequent tooling to be more adequately con-

trolled during following machining operations. In

order to ensure that the correct tool has been selected,

it is really only down to basic ‘good engineering prac-

tices’ , namely:

•

that the initial selection of criteria for the cutting

data is sound;

Table 11. Cutting insert surface texture and contact stress severity data.

← 10k

local

/E* [°] →

Tool finish: Surface texture data:

Al/HSS: Cu/HSS: Brass/WC Steel/WC

Ra [µm] ∆q [°]

CVD-coated 0.2-0.5 3-7 1.2 1.9 2.8 1.8

Ground 0.1-0.25 2-4 1.2 1.9 2.8 1.8

Super-nished 0.03 0.4 1.2 1.9 2.8 1.8

* When

s/k is <0.5, an asperity is totally elastic – if the plasticity index is <5 and totally plastic if its >50.

As s/k increases to 1, these critical plasticity index values reduce. In large s/k conditions of metal machining, an asperity would normally be

‘fully-plastic’ , if:

∆q ≥ 10k

local

/E*.

NB ‘s’ = Shear strength and ‘k’ = local shear stress.

[Source Childs, et al., 2000]

.

Machinability and Surface Integrity