Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_8 doc

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (890.74 KB, 9 trang )

Figure 173. Finite Element Method (FEM), to obtain simulated, but realistic data on isother-

mal temperatures within the cutting region. [Source: Tay et al., 1993]

.

Chapter

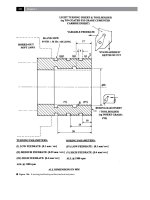

Figure 174. Typical wear patterns that could be present on a cemented carbide (uncoated) cutting insert, utilised

under ‘steady-state’ turning conditions

.

Machinability and Surface Integrity

•

good quality and consistent workpiece material is

to be utilised;

•

that the condition monitoring of machine tool en-

sures that it is in an optimum state for use;

•

any ood coolant supply and quality – if it is to be

used – is of the correct grade and dilution concen-

tration;

•

work-holding/support is both rigid and precise/ac-

curate;

•

expert support is available – if necessary – along

with the user’s own practical experiences.

ese factors oer a good ‘start-point’ in ensuring that

the ‘ideal’ tool wear development takes place.

Classification of Tool Wear Types

Tool wear depends on several inter-related factors,

some of these have been mentioned above, but are

worth restating, such as: the cutting insert and work-

piece material combination – plus their physical,

mechanical and chemical properties; cutting insert ge

-

ometry; as well as cutting uid properties and pressure

– if applied; together with various other operational

parameters – cutting data selected, stability of the cut-

ting process and work-holding application techniques.

Any knowledge obtained on analytical studies of wear

mechanisms, is largely based upon the results from ex-

perimental trials. Simply obtaining wear data presents

considerable diculties, then simply analysing these

results can be somewhat onerous, due to isolating the

major cause of this particular wear regime. Neverthe-

less, having stated these problems, many potential so-

lutions to specic wear patterns can be found, so long

as the actual wear regime, or composite wear behav-

iour can be singularly identied. With this in mind,

the following classications for tool wear are given be-

low (i.e. see Fig. 174 for of several these wear patterns),

which include:

•

Flank wear – as its title suggests, occurs on the cut-

ting edge’s anks, usually the result of an abrasive

wear mechanism. Both of the clearance faces – lead-

ing and trailing edges, together with the tool nose

radius are subject to a parallel land wear, created by

the workpiece travelling past the contact regions of

the tool both during and aer chip formation. Such

a wear mechanism is considered normal tribologi-

cal behaviour and a progressive form of ank wear

can be tolerated and subsequently dealt with, by an

ecient tool-changing strategy, based upon antici-

pated tool life expectancy.

NB Toward the end of the steady-state and progres-

sive ank wear regime, it could lead to several un-

desirable factors, such as: increasing friction, which

can possibly change the insert’s prole – leading to

poor machined surface texture, or dimensional in-

accuracies as the ‘tool dris’

63

– creating variability

in tolerances of successive parts.

•

Crater wear – this is present on the rake, or chip

face and is normally the result of a combination

of an abrasion and diusion

64

wear mechanism.

63 ‘Tool driing’ , is a term used to describe the fact that having

initially set the tool to a particular dimensional size, the tool’s

ank will progressively wear – under steady-state machin-

ing conditions. e variability in dimensional size can be the

subject of both random and systematic errors – even when

the operation is behaving normally. is dimensional variabil-

ity, causes for example: turned diameters to get larger, while

drilled holes get smaller – as successive components are ma-

chined, this is the essence of tool-driing. e term process

capability* has been coined to explain the stochastic process

output from a normally-operating production process – see

Chapter 2, Footnote 26, for more information regarding this

subject.

*Process capability (C

p

) can change during consecutive pro-

duction output of components, being the result of the ‘vari-

ables’ (i.e. as each singular part dimension is known), pro-

ducing either random, or systematic errors, or both, as the

production run progresses. is is why it is usual practice to

utilise ‘Statistical control techniques’ to show any signicant

changes in output. erefore, ‘Shewart charting techniques’

in combination with ‘Probability paper’ are employed, to esti-

mate the: C

p

value and to determine if the process is behaving/

operating ‘normally’ – usually a ‘normal output’ is signied by

establishing a ‘straight-line’ (i.e. plotted) relationship on the

‘Probability paper’.

64 ‘Diusion wear’ , was initially proposed in 1858 by the Ger-

man physiologist Adolph Fick (1829–1901), where he enun-

ciated laws governing the diusion of substances generally

on a quantitative basis. Today, we are concerned with ‘atomic

migration’ within metallic solid solutions. Fick produced two

laws, with Fick’s 1

st

Law stating: ‘at the amount (J) of a ma-

terial moving across a unit area of a plane in unit time is pro-

portional to the concentration gradient (∂c/∂x) at the same time

but of opposite sign’. It can be expressed as follows:

J[atoms/m

2

.s] = − D [m

2

/s](∂c/∂x)[atoms/m

3

.1/m] Fick’s 1

st

Law Where: J = ux, net ow of atoms; D = diusion coe-

cient; ∂c/∂x = concentration gradient.

NB Assuming that X-axis is parallel to direction in which

concentration gradient is operating. Fick’s 2

nd

Law was de-

rived from the 1

st

Law and from the fact that matter is con-

served, relating the change in concentration with time (∂c/∂t)

and it can be expressed as: (∂c/∂t) = ∂/∂x (D∂c/∂x)

Fick’s 2

nd

Law (General case) By dierential calculus, this 2

nd

Law changes to: ∂c/∂t) = D ∂

2

c/∂x

2

.

Chapter

e crater can be formed either via a hard-particle

grinding action, which mechanically-removes rake

face surface layers, or by a complex ‘atomic diusion

process’

65

interacting between the chip and the tool

material (ie see Fig. 174 – top right).

NB If a cutting insert has high bulk hardness,

combined with ‘hot-hardness’

66

, plus minimum af-

nity between these two materials, this will dimin-

ish any crater wearing tendencies. Moreover, crater

wear changes the cutting insert geometry of the

edge, which may impair chip formation and modify

cutting forces, or lead to a weakened edge strength.

Many of today’s multi-coated cutting inserts are less

aected by crater wear than their uncoated coun-

terparts.

NB From this it can be appreciated why the nal stages of dif-

fusion are somewhat slow, due to the rate of diusion decreas-

ing as the concentration gradient diminishes. (Higgins, 1979)

65 ‘Atomic diusion process’ , there is strong evidence – when

ferrous workpiece machining – to indicate that cratering of

WC-Co cutting inserts (i.e. uncoated), occurs by diusion of

the C atoms into chip at the interface (i.e see Fig. 174 – top

right schematic diagram). Remembering that solid-state dif-

fusion depends upon the rate at which the tool’s atoms dis-

solve/diuse into the chip. For WC, the most rapid diusion is

by the tool’s Co atoms – of the carbide bond and, the Fe atoms

from the chip. Hence the carbide grains are undermined and

swept-away for two reasons:With WC tool material, carbide

grains are not isolated and constitute the bulk of the mate-

rial, so support each other in a ‘rigid framework’ ,Due to Co

atoms from the tool ‘diusing-out’ , so Fe atoms from the chip

‘diuse-in’ and these provide support for the carbide grains,

which in turn inhibit their removal. In the chip, C atoms being

small, rapidly diuse through the Fe matrix, however those in

the tool are strongly-bonded to W and are not free to move by

themselves. us, the rate of diusion of both W and C atoms

together from the tool go into the chip and thus, will control

diusion wear with respect to its temperature – as Fick’s Laws

suggest.

NB e distances for diusion at the tool/chip interface are

between 1 nm up to 1µm. Diusion in the tertiary shear zone

(i.e. ank) is normally higher than in the secondary shear

zone, due to the signicantly greater workpiece surface speed

in this vicinity. So, not only is attrition a mechanism for ank

wear, diusion is also partly responsible – even when the rake

face is hardly worn. In appearance, when the grains look to

be smooth, this is a good indication of a diusion mechanism

taking place. (Armarego and Brown, 1969)

66 ‘Hot hardness’ , this is the ability of a cutting insert to retain

its relative bulk hardness and hence geometry at elevated tem-

peratures.

•

Plastic deformation – occurs when high pressures

(i.e. compression) are exerted on the cutting edge

in combination with elevated temperatures. Con-

ditions likely to create plastic deformation on the

cutting insert are when high speeds and feeds are

utilised on workpiece materials that are prone to

work-hardening. Tool materials must have the re-

quired mechanical properties to withstand plastic

deformation during machining. Typically, bulging

of the edge in the tool nose region, leads to: geom-

etry deformation; chip ow modication; greater

localised temperatures – until a critical juncture is

attained. So cutting insert ‘hot-hardness’ is a vital

characteristic.

NB In order to combat cutting insert plastic defor-

mation, a large tool nose radius, plus more robust

tool geometry adds greater strength in this ‘exposed

region’ of the tool.

•

Notch wear on insert’s leading edge – is the result of

mechanical action, promoted by either machining

workpiece materials that may easily work-harden,

so each successive longitudinal turning pass at the

same D

OC

leads to the previous surface condition

being harder, resulting in a more abrading-action

here – hence a notch will wear at this point on the

insert‘s ank. is ‘notching eect‘ can be reduced,

if a variable D

OC

is employed, to ‘even-out’ the con-

tact region along the leading edge of the insert.

NB ‘Black-bar stock’ having been hot-rolled from

its primary processing route, tends to have a hard

and abrasive oxide scale to its periphery, which may

contribute to insert notching when only the surface

is ‘skimmed’ by a longitudinal turning operation.

•

Notch wear on insert’s trailing edge – occurs by in

the main, by adhesion wear, but to a lesser extent,

may be the result of an oxidation wear mechanism.

e notch on this ank’s trailing edge is formed

where the cutting edge and the workpiece material

separate.

NB Notch wear here, tends to be very localised to-

ward the end of the cut, enabling air to reach this

cutting vicinity, which has a high temperature pres-

ent, so adhesion/oxidation can be expected.

•

Built-up edge (BUE) formation – is usually the re-

sult of tool/workpiece anity associated with tem-

Machinability and Surface Integrity

perature and its respective cutting speed (i.e. see

Fig. 28). Moreover, it can also transpire as a result

of ‘edge agging’ , or from other wear mechanisms.

is ‘cold’ pressure-welded workpiece material be-

ing attached to the tool as a BUE, changes the cut-

ting insert’s geometry – to its detriment. Hence,

this BUE is both severely work-hardened and

‘unstable’ – it will break-away from the tool mate-

rial thereby potentially ‘frittering’ the insert’s edge.

NB BUE machining data conditions have been

reasonably well-dened, so fortunately, these re-

spective cutting speeds can be avoided, particu-

larly, as most CNC machining operations happen at

much higher speeds and modern insert grades and

coatings, minimise this BUE eect. If BUE does oc-

cur, it can create a poor surface nish on the ma-

chined surface. In any BUE machining condition,

if it continues without attention, then the result can

be rapid edge breakdown, or even result in insert

fracture.

•

e former conditions are in the main, conned

to continuous cutting and steady-state machining

conditions, albeit with single-point cutting inserts.

•

e latter conditions are generally restricted to in-

termittent cutting multi-point machining, or inter-

rupted cutting operations:

•

ermal cracking – is usually the result of fatigue

wear, produced by thermal cycling machining con-

ditions, such as when milling. ese cracks that

form are normally at 90° to that of the cutting edge

67

.

ese cracks are spaced out periodically along the

cutting edge and when they propagate (i.e. grow) to

67 ‘ermal fatigue cracks’ , are usually termed ‘comb-cracks’ –

due to their appearance is not unlike that of a hair comb. When

these cracks propagate to a critical length which can be ex-

plained in terms of ‘Fracture mechanics’* and in particular the

‘stress intensity factor’ (K

IC

) – with the ‘C’ standing for ‘critical’.

Such cracks will fracture quickly around the ‘Speed of sound’

(i.e. Mach 1, or in a steel workpiece @ 5050 ms

–1

), so little, if

any warning is given of the likely failure condition as it arises

– when the tool’s edge eventually catastrophically fails.

*In 1957, G.R. Irwin and his co-workers, laid the foundations

for ‘Fracture mechanics’ and were particularly noted for the

mathematics for dening the ‘stress intensity factor’ (K), spe-

cically:

K = σ √ (πc) [Nm

½

]

Where: σ = fracture stress, c = half length of an internal aw.

(Shaw, 1984)

a critical size, bulk tool material will be pulled-out

of the tool’s edge – leading to a very rapid type of

cutting insert edge failure.

NB Varying the chip thickness will also aect tem-

peratures throughout the cut. A cautionary note

here, concerning cutting uid application: if used

under certain conditions, the cutting uid has a

detrimental inuence in some metal cutting opera-

tions, as it amplies the variations in temperature

between and in- and out-of-cut.

•

Mechanical fatigue cracking – may be present if

cutting force shock-loads are extreme. Fatigue

68

is

a form of fracture which is promoted by continual

variations in load, but where the load in itself, is not

great enough to cause fracture.

68 ‘Fatigue’ , can be dened as a: ‘Phenomenon leading to the fail-

ure of a part under repeated, or uctuating stress below the ten-

sile strength of the material.’ Failure usually occurs suddenly as

a result of crack propagation without plastic deformation at a

stress level well below that of the elastic limit for the material.

e stress can be either an: ‘alternating’; ‘repeated’; or a combi-

nation of these types. At a discontinuity such as a notch, hole,

or step, the stress is considerably greater and is termed a ‘stress

concentration factor’ (K). Graphs can be plotted , such as:

SN curves (i.e. to nd the endurance limit for steels, or for

non-ferrous metals, alloys and plastics -the fatigue stress

‘σ

FS

’ is specied for a nite number of stress reversals),

Soderberg diagram – for steel, with alternating stress plot-

ted against steady stress. Moreover, a ‘safety factor’ (FS) can

be applied to the graphical result, as follows:

(Safety factor)

FS =

σ

y

σ

m

+(σ

y

�σ

e

)K σ

r

Where: σ

y

= yield stress, σ

m

= steady stress component,

σ

e

= failure occurs – (i.e. above a line drawn from this value:

σ

e

on the ‘Y-axis’ to σ

u

on the ‘X-axis’); Kσ

r

= alternating com-

ponent – with ‘K’ representing the ‘stress concentration factor’

and ‘σ

r

’ representing ‘alternating stress’.

NB Most steels have an ‘endurance limit’ being about half its

tensile strength, with an approximation oen utilised:

For steels: Endurance limit = 0.5 tensile strength (i.e. up to

a tensile strength of 1400 N mm

–2

), Endurance limit = 700

N mm

–2

(i.e. above a tensile strength of 1400 N mm

–2

).

For Cast steel/iron: Endurance limit = 0.45 tensile strength (i.e.

up to tensile strength of 600 N mm

–2

), Endurance limit = 275

N mm

–2

(i.e. above a tensile strength of 600 N mm

–2

).

Non-ferrous metals/alloys: there is no endurance limit and

the fatigue stress is taken at a denitive value of stress rever-

sals, e.g. 5 x 10

7

. (Carvil, 1994, et al.)

–

–

Chapter

NB erefore at the initiation of a cut, the varia-

tions in the magnitude of the cutting force and its

direction, may not be too great for both the tough-

ness and strength of the cutting insert. With con-

tinual usage however, these fatigue cracks grow – in

the main – parallel to the cutting edge and may

eventually be the cause for premature tool failure.

•

Cutting edge chipping – this transpires when the

edge line fractures, rather than being the result of

wear. It can be considered as a form of fatigue fail-

ure, because of the cycles of loading and unloading

during cutting, leading to particles of tool material

being removed from the insert’s surface. is type

of wear mechanism is generally the result of inter-

mittent cutting operations.

NB An investigation into whether this edge wear

is either from chipping, or the result of ank wear.

‘Spalling’ (i.e. cracking, or aking of the surface)

and ‘nicking’’ are also variants of this category of

edge degeneration.

•

Fracture – is normally catastrophic conclusion to

the cutting process (i.e. see Fig. 175). Here, bulk

material fracture can have serious consequences

obviously to the cutting insert, but also aecting

the machined part. Moreover, this form of edge

fracture is more oen than not, the termination of

alternative wear regimes.

If Fig. 175 is investigated in more detail, it may help

comprehension of the nature of the serious problems

associated with such a sudden failure mode. e cut-

ting insert was purposely catastrophically failed in

practical trials conducted by the author, using a rea-

sonably robust turning and facing geometry, longitu-

dinal turning P/M ferrous compacts without coolant.

Here, the cutting speed was raised by 25% above the

optimum, with the feedrate 40% greater than usually

specied. is ‘abusive machining regime’ , created

high ank wear and plastic deformation to the cutting

edge, which shortly failed – catastrophically. In Fig.

175c, detail of the fracture surface indicates both duc-

tile and brittle failure modes instigated from the worn

leading edge’s ank. By increasing the cutting data by

just the cutting speed alone and leaving the feedrate

at the optimum, tool life was reduced on other simi-

lar inserts, but catastrophic failure did not occur, only

very high levels of ank wear. However, if the cutting

speed was kept at the optimum and the feedrate was

increased – as mentioned – in-line with other insert

trials, then catastrophic failure eventually occurred,

well before that predicted by ‘Taylor’s tool life calcu-

lation’ . is conrmed the fact that the high abrasive

nature to the testpieces produced from ferrous-based

P/M compacts, in combination with an increased fee-

drate caused premature catastrophic failure of the cut-

ting inserts during these ‘harsh’ machinability trials.

As previously mentioned, Appendix 11 has a con-

cise ‘trouble-shooting guide’ for some of the potential

wear regimes that are likely to be experienced during

many machining operations.

.. Tool Life

Introduction

It is normal practise to assess tool life according to

three mutually-inuencing criteria, as any one of them

could be the reason for the expensive business of sub-

sequent part scrappage. ese criteria that signicantly

aect machined components and can be the reason for

curtailment of the cutting tool’s life are:

1. Ability to sustain workpiece tolerances – here if

the tool has been in operation for too long ‘in-cut’ ,

then this will increase the tendency for ‘tool dri-

ing’ which will amplify machined component vari-

ability, while creating inconsistency in part produc-

tion (Figs. 31ci and ii),

2. Maintaining machined surface texture quality – as

the tool is progressively utilised, the ank and cra-

ter wearing tendencies will increase, leading to de-

generation of the surface texture, below that which

was demanded from the designer’s direct engineer-

ing requirements (i.e. see graph in Fig. 148),

3. Eciency in chip-breaking ability – if the cut-

ting insert/tool has been operated for considerable

time, there is every expectation that both ank and

more importantly crater wear will be present. is

will have an adverse eect on chip-breaking ability,

leading to either poor component surface texture,

or variability in component tolerances, or both

(Figs. 37 and 38a and b).

If a cutting insert, or tool no longer satises the above

wear criteria, its useful life is ended and it should be

summarily discarded. e tool life’s predictability, is a

key factor in an estimation of the anticipated produc-

tivity output level. Approached from a dierent direc-

tion, an CNC programmer may deliberately choose

Machinability and Surface Integrity

Figure 175. Catastrophic failure of a turning insert.

Chapter

the cutting insert, or tool they are most familiar with,

because they know – from practical experience – that

it performs and wears in a progressive manner, rather

than the unpredictability associated with an insert of

‘uncertain machining capability’ that might otherwise

prematurely fail.

Prior to discussing criteria for determining when

a cutting insert is ‘worn-out’ , it is necessary to estab

-

lish in practice, what this actually means. For example,

does ‘worn-out’ refer to when the: dimensional accu-

racy becomes unpredictable: or if the surface nish has

signicantly deteriorated; or perhaps the fact that its

automatic chip-breaking behaviour has become inef-

cient? In many situations it is by the user’s experience

that one can judge how much ank wear can be toler-

ated on the cutting edge before machining is discon-

tinued. As a rule, ank wear is a dependable criterion

for assessing when the cutting edge is eectively worn-

out. Moreover, from the previous discussion, perhaps

the degree of cratering may in certain machining cir-

cumstances prove to be more signicant than the ank

wear, in respect to the shortening tool life.

Tool wear can be established by several techniques,

but the usual method is to observe and then measure

the actual wear as it progressively develops. e eec-

tive cutting time, or tool life ‘T’ , is specied as time-

elapsed prior to a predetermined degree of wear has

been reached. A typical procedure for determining

ank wear can be: to observe cutting edge(s) in-situ on

the machine tool; then remove from the machine and

visually inspect the tooling; followed by its respective

wear rate can then be optically magnied in suitable

equipment allowing accurate dimensional measure-

ment – against the following criterion (i.e. see Fig.

174):

•

Extent of ank wear from original edge – if this

wear is of relatively uniform nature, it may be dis-

tributed across three zones, ‘A’ ,‘B’ and ‘C’. e

mean ank wear ‘V

B,C–A

’ is measured over the cut-

ting region of the leading edge across these zones –

it is oen just referred to as simply: ‘V

B

’. If excessive

wear develops at one position on the cutting edge,

for instance where the wear-notch ‘V

N

’ occurs, this

zone is usually ignored when establishing the ‘mean

wear’. Here and under these conditions, it is usual

to quote the maximum ank wear as ‘V

Bmax

’ ,

•

Extent of cratering – this is usually specied by

the maximum crater depth from the plane of the

original rake face ‘K

T

’ and in some cases, by its di-

mensional size: ‘K

B

’- width and ‘K

M

’ – length (not

shown).

e above wear criteria, are normally utilised for esti-

mating the extent of ank and crater wear. Over many

years of experimental research into tribological wear

mechanisms, it has been established that progressive

ank wear develops according to a xed pattern, with

three distinct stages to this wear regime, they are (Fig.

176):

1. Initial, or primary wear – if a new cutting edge

is used to machine a workpiece, there is a rapid

breakdown of the of the cutting edge. is early

ank wear on the tooling is depicted in the graph

of wear against time in Fig. 176a, indicated by its

preliminary high wear-rate, is wear-rate is de-

pendent upon the cutting conditions and type of

workpiece material, plus any cutting uid applica-

tion – if utilised. Flank wear increases in relation to

an higher cutting speeds,

2. Progressive, or secondary wear – occurs aer the

initial ank wear has taken place. During the fol-

lowing time period, there is a steady and progres-

sive stage to the cutting tool’s/insert’s wear, with a

much less pronounced increase than that indicated

at the initial wear stage, this is when the productive

machining output occurs. Toward the end of this

progressive wear stage, this being the case when the

ank wear ‘V

B

’ reaches approximately 0.8 mm in

height, here, it is normal practice to replace this old

tool with a ‘sister tool’ – to continue machining the

component batch, or production run. Once ank

wear has reached this arbitrary dimensional value,

then to all practical purposes its productive life is

ended,

3. Catastrophic, or tertiary wear – will normally only

become apparent if the tool is taken toward, or up

to, its complete failure. Such catastrophic failure

is the result of a combination of several tool wear

mechanisms: high ank wear; large crater forma-

tion – reaching the point where the tool has been

suciently weakened for the increased tool forces

now operating to cause it to fracture. Inevitably, if

such an immediate breakdown occurs during the

nal pass over the workpiece’s surface, it is prob-

able that the component has to be scrapped. If the

workpiece has a high residual raw-stock value, then

aer machining, signicantly more added-value

will have accrued. So, any initial savings made by

using these tools into the tertiary ank wear stage,

will be more than cancelled-out by scrapping this

component!

Machinability and Surface Integrity

Tool-life Diagrams

Machinability is a subject that has yet to be fully-de-

ned and analysed, in particular the interactive mech-

anisms that take place at the chip/tool interface, with

the user’s own experience being a good start-point for

any future machining operations. As has been men-

tioned above, tool wear varieties can have several dif-

fering causes and eects (i.e. see Appendix 11). With

any machining batch, or production run, it is custom-

ary practice to establish a ‘norm’ for both the tolerable

ank wear dimension and the depth/size of crater for-

mation. In particular, as the ank wear pattern usu-

ally takes in-cut time to progressively develop and this

predictable tool/wear relationship has been well estab-

lished some years ago, initially by F.W. Taylor’s pio-

Figure 176. Tool wear under steady-state conditions: (a) tool wear as a function of time, (b) if cutting speed

is changed, then tool life is aected, (c) amalgamation of these ‘Taylor curves’ and derivation of the ‘general

taylor curve’. [Courtesy of Sandvik Coromant]

.

Chapter