Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_10 ppt

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (778.49 KB, 9 trang )

bration certicate, to ensure that the results obtained

are both valid and sound. A cautionary note: if the dy-

namometer has been inadvertently dropped, or it has

possibly collided with an obstruction when in use on

the machine tool, it should be sent back to the manu-

facturer for servicing and recalibration, otherwise,

spurious cutting force data may be the result.

7.9 Machining Modelling

and Simulation

Introduction

Previously, it was been widely accepted that most cut-

ting tool modelling technqiues are somewhat incom-

plete, in both their analysis of the process and their

accompanying derived mathematics. Early, but worthy

attempts at analysing the chip formation mechanics of

the orthogonal cutting process were undertaken ini-

tially by Ernst and Merchant (1941) – shown schemat-

ically depicted in Fig. 181, followed by further work

concerning the analytical graphical interpretation of

the orthogonal cutting action which was presented

by Merchant and Zlatin (1945) and later work by Lee

and Shaer (1951) – not shown. is earlier work

was then followed by Zorev’s (1963) interpretation of

an ‘idealised cutting model’ (Fig. 182). In all of these

above modelling cases and others not mentioned – for

brevity’s sake!, the very complex nature of the cutting

process, is a vast subject ‘straddling’ many engineering

and physical disciplines. Such modelling involves as-

pects of: the tool’s geometry, chip/tool contact lengths

and pressures, chip formation, cutting forces, fric-

tional and thermal factors and so on, making it vir-

tually impossible to obtain close agreement between

with any truly meaningful results between each pro-

posed model. is lack of correlation of these model-

ling processes, is to be expected, as in reality a shear

zone, rather than a shear plane exists, but for mathe-

matical treatment, a shear plane allows some degree of

geometrical association. Due to the complex nature of

the inter-related variables that occur in any dynamic

cutting situation for just simply the orthogonal cutting

process, let alone for oblique machining modelling,

this has meant that the ‘optimum modelling solution’

has as of now, not yet been fully addressed.

Many ‘learned tomes’ have been written in the past,

concerning the ‘mechanics of machining’ and it is not

the intention to fully discuss them here, in this book

which is principally concerned with ‘current practice’

concerning machining applications. However, a brief

resumé of just one of these ‘orthogonal models’ shown

in Fig. 181 will be mentioned below, together with a

concise review of friction in metal cutting operations

(Fig. 182) will be presented, to attempt to show why

the subject of ‘theoretically modelling’ the cutting pro-

cess is so complicated.

Ernst and Merchant’sComposite Cutting Force Circle

If a continuous chip formation is produced when ma-

chining ductile materials in an orthogonal cutting

process, such as that found when cylindrically turn-

ing a component’s periphery with an undeformed chip

thickness (‘t

1

’), this will cause a chip compression (‘t

2

’)

– Fig. 181(top). e cutting forces can be obtained by

employing a cutting force dynamometer as discussed

in the previous section, to typically measure the forces

‘F

C

’ and ‘F

T

’ and so on. By utilising such cutting tool

dynamometry, Ernst and Merchant (1941) were able

to classify the forces acting in the vicinity of metal cut-

ting which gave rise to both local plastic deformation

and frictional eects. In Ernst and Merchant’s theory

which is oen termed the so-called ‘shear-angle solu-

tion’ , it is assumed that the cutting edge is always per-

fectly sharp and that a continuous-type chip without

BUE occurs, this former assumption in practice does

not actually occur. Moreover, another assumption in

their analysis it was that the chip would behave like

a ‘rigid body’ , which is held in equilibrium by the ac

-

tion of the applied forces transmitted across the tool/

chip interface and transversely over the shear plane.

Boothroyd (1975), oered a reasonably ‘elegant solu-

tion’ to Ernst and Merchant’s numerical and geometri-

cal analysis and, this has been somewhat modied and

further simplied below. In order to abridge the ‘shear-

angle solution model’ shown in Fig. 181, the resultant

force ‘R’ is depicted acting at the tool’s cutting edge,

being resolved into components ‘N’ and ‘F’ in direc-

tions along and normal to the tool’s face respectively,

as well as into components ‘F

N

’ and ‘F

S

’ – once again,

along and normal to the shear plane correspondingly.

Further, the cutting force ‘F

C

’ and the thrust ‘F

T

’ com-

ponents of the resultant force, are also shown. Here, it

can also be assumed that the entire resultant force is

transmitted across the tool/chip interface and that on

both the tool’s ank and edge no force occurs, mean-

ing that a zero ‘ploughing-force’ is present – see Fig.

184 which illustrated this ‘nose-rounding eect’.

Chapter

e foundation purported by Ernst and Merchant’s

theory, was the proposition that the shear angle ‘φ’

would acquire such a value, thereby reducing the ac-

tual work done to a minimum. In view of the fact that

that for preselected cutting conditions, the work done

during cutting was comparative to that of ‘F

C

’ in terms

of ‘φ’ , hence allowing one to obtain the value of ‘φ’

when ‘F

C

’ is at a minimum. us, from Fig. 181:

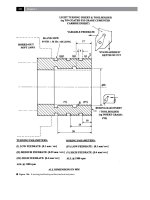

Figure 181. ‘Merchant’s’ composite metal cutting circle for an orthogonal cutting model, where:

• F

T

= thrust force component,

• F

C

= cutting force component,

• F

N

= normal force component on the shear plane,

• F

S

= shear force component on shear plane,

• R = resultant tool force component,

• N = normal force component on tool face,

• Φ = shear angle,

• α = working normal rake angle,

• τ = mean friction angle on tool face,

• t

1

= undeformed chip thickness,

• t

2

= deformed/compressed chip thickness,

• A

0

= cross-sectional area of uncut chip,

• A

c

= cross-sectional area of deformed/compressed chip.

NB: Force arrow vector directions have been reversed and some terms have been modied from the original

work. [Source: Ernst & Merchant, 1941]

.

Machinability and Surface Integrity

F

S

= R cos(φ + τ – α) (i)

and

F

S

= τ

S

A

S

= τ

S

A

C

/sin φ (ii)

Where:

τ

S

= Workpiece material’s shear strength – on the

shear plane,

A

S

= Shear plane’s area,

A

C

= Uncut chip’s cross-sectional area,

τ = Mean friction angle, between too and chip [i.e.

arctan (FT/FN)],

α = Normal rake angle (i.e. working).

From equations (i) and (ii):

R =

τ

s

A

c

sin ϕ

cos(ϕ + τ − α)

(iii)

By geometry:

F

C

= R cos(τ – α) (iv)

Hence, from equations (iii) and (iv):

F

c

=

τ

s

A

c

sin ϕ

cos(τ − α)

cos(ϕ + τ − α)

(v).

Now, equation (v) can be dierentiated with respect

to ‘φ’ , then equated to zero to obtain a value of ‘φ’

when ‘F

C

’ is at a minimum. Hence, the requisite value

is specied by:

ϕ + τ − α =

π

(vi).

In comparative analysis undertaken by Merchant

(1945), he found close correlation with experimental

results was obtained when machining synthetic plas-

tics, but a somewhat poor theoretical correlation oc-

curred when steel had been machined with cemented

carbide tooling. It needs to be mentioned that when

Merchant dierentiated with respect to ‘φ’ , it was as-

sumed that ‘A

C

’ , ‘α’ and ‘τ

S

’ would be independent of

‘φ’ , but on further consideration, Merchant decided to

oer in a ‘modied theory’ the relationship of :

τ

S

= τ

So

+ kσ

S

(vii).

Here, Merchant brought in a modication to the shear

strength of the workpiece material ‘τ

S

’ which now in-

creased linearly with an increase in normal stress ‘σ

S

’

on the shear plane, where zero normal stress ‘τ

S

’ is

equal to ‘τ

So

’. is new assumption by Merchant was

conrmed by previous work undertaken in the litera-

ture published by Bridgman (1935, ’37 and ’43), where

the shear strength when experimental machining of

polycrystalline metals was shown to be dependent on

the normal stress on the ‘plane of shear’.

Now from Fig. 181, we can obtaing the following

relationship:

F

Ns

= F sin(φ + τ – α) (viii)

and:

F

Ns

= σ

S

A

S

=

σ

S

A

C

sin ϕ

(ix).

From equations (viii) and (ix):

σ

S

=

sin ϕ

A

C

R sin(ϕ + τ − α)

(x).

Combining equations (iii) and (x):

τ

S

= σ

S

cot(φ + τ – α) (xi)

and, from equations (vii) and (xi):

τ

S

=

τ

So

− k tan(ϕ + τ − α )

(xii).

is equation (i.e. xii), explains why the value of ‘τ

S

’

may be inuenced by modications in the shear angle

(‘φ’), which is now inserted into equation (v), to ob-

tain a new equation for ‘F

C

’ in terms of ‘φ’ , therefore,

the resulting expression becomes:

F

C

=

τ

So

A

C

cos(τ − α)

sin ϕ cos(ϕ + τ − α)[ − k tan(ϕ + τ − α)]

(xiii).

Now, it can be assumed that both ‘k’ and ‘τ

So

’ are con-

stants for the specic workpiece material, further, that

‘A

C

’ and ‘α’ are also constants for the machining op-

eration. Hence, equation (xiii) can now be dierenti-

ated to obtain a new value of ‘φ’ , with the resulting

expression:

2φ + τ – α = C

Where:

C = Can be obtained from ‘arccotk’ , which is a con-

stant for the workpiece material.

NB In further more recent experimental work, it has

been shown that ‘τ

S

’ will remain constant for a speci-

ed workpiece material, across a diverse range of cut-

Chapter

ting conditions, as such, the value of ‘k’ can be equated

to zero.

When the shear-angle values are compared for the

plotted linear relationships of the earlier theoretical

and experimental work undertaken by Ernst and Mer-

chant, to that of the later comparative work by Lee and

Shaer, then these shear-angle relationships diverge

somewhat. However, one area that these researchers

both agreed upon, was the fact that friction on the

tool’s face was the most important factor during metal

cutting. In the following discussion, the inuence that

frictional behaviour has at the tool/chip interface will

be briey mentioned.

Frictional Effects During Machining

For simplicity’s sake, friction between dry sliding sur-

faces will be concisely reviewed. In 1699 Amontons

‘laws of friction’

78

were formulated, then veried by

Coulomb

79

in 1785, with Bowden and Tabor (1954)

contributing greatly to an explanation of these empiri-

cal laws.

If two apparent at surfaces are placed together, the

larger asperities (i.e. peaks) on each mating face will

only establish contact. With just normal loading, the

top of these asperities will yeild, creating a real area

of contact until such a time, that they are capable of

supporting an applied load. In the main, for the vast

majority of engineering applications this real contact

area (‘A

r

’), is normally only a very minute portion of

the apparent real of contact (‘A

a

’) – even aer the con-

tacting asperities of the soer material has plastically

deformed (i.e. yielded). us:

A

r

= F

n

/σ

y

(i)

78 ‘Law(s) of friction’ , Amontons in 1699 stated in the main,

that: ‘Friction is independent of the apparent area of contact

and proportional to the normal load between two [mating] sur-

faces.’

79 Coulomb (1785), conrmed these ‘frictional laws’ with the

observation that: ‘e coecient of friction* is substantially in-

dependent of the speed of sliding.’

*Coecient of friction (µ) = F/N

us, the friction force is proportional to the perpendicular

force between contacting surfaces and is independent of the

surface area, or its ‘rubbing speed’.

Where:

F

n

= Normal force,

σ

y

= Yield pressure of the soer material.

us, for most metallic materials, this close asperity

contact between mating surfaces creates localised ‘cold

welding’. Prior to any sliding with respect to these two

contacting surfaces, a force is necessary to continually

shear potentially contacting and reforming asperity

tips of these ‘welded junctions’. Hence, the total fric-

tional force ‘F

f

’ is given by:

F

f

= τ

f

A

r

(ii)

Where:

τ

f

= Shear strength of soer contacting material,

A

r

= Real contact area.

From equations (i) and (ii), the actual coecient of

friction (‘µ’) between these contacting surfaces will

be:

µ = F

f

/F

n

= τ

f/

σ

y

(iii).

In majority of machining operations typied by the

continuous turning of metallic workpieces, the coef-

cient of friction (‘µ’) at the chip/tool interface can

vary quite considerably. Its frictional variation, being

inuenced by any changes in: cutting speed, feedrate,

rake angle contact regions – this latter factor is par-

ticularly relevant for multi-functional tooling, where

the cutting insert’s top face is not planar (i.e at). In

modern machining practice, the normal pressures ex-

erted at the tool/chip interface are exceedingly high,

typically when machining commercial grades of me-

dium carbon plain steels these pressures are >3.5 GPa.

is high normal pressure at the ‘interface’ causes the

real contact area to approach that of the entire area,

where: A

r/

A

a

= unity! is means that under these cir-

cumstances the ordinary laws of friction no longer ap-

ply, and the frictional force ‘F

f

’ is still represented by

equation (ii), but is now independent of the normal

force ‘F

n

’. is acute change in the frictional behaviour

during machining, means that the shearing action is

not conned only to the interface asperities, but in-

cludes workpiece material in the local substrate.

In work published by Zorev in 1963, his ‘model’

considered the frictional behaviour in continuous

metal cutting operations where no BUE was present

(Fig. 182). Under these machining conditions, Zorev

Machinability and Surface Integrity

noted that the normal stresses at the tool/chip inter-

face were suciently high enough to cause ‘A

r/

A

a

’ to

approach unity, over the zone denoted given by length

‘l

st

’ (Fig. 182) – this being termed the ‘sticking region’

80

– also see magnied quick-stop photomicrograph in

Fig. 184(top) showing the aect on the resultant chip.

e ‘sliding region’ , extends from from the end of the

‘sticking region’ to a point where the chip loses contact

with the rake face (i.e. ‘l

f

’-‘l

st

’), here, the ‘A

r

/A

a

’ ratio is

less that unity – meaning that the coecient of friction

is constant. In 1964, Wallace and Boothroyd produced

evidence that the ‘sticking manner’ observed on the

underside of the chip had abruptly stopped. ey ob-

served that in an adjacent vicinity to that of the tool’s

cutting edge, grinding marks on the rake face were im-

printed onto the chip’s underside. is phenomenon

indicated that no relative motion between the chip and

the tool had occurred, suggesting that here, the ‘real’

and ‘apparent’ areas of contact were ‘equalised’ in this

region. erefore, under ‘sticking friction’ conditions,

the ‘mean angle of friction’ on the rake face, depends

on the:

1. Form of the normal stress distribution,

2. Tool/chip contact length (i.e. ‘

l

f

’),

3. Mean shear strength of the chip material – in the

‘sticking region’ ,

4. Coecient of friction – in the

‘sliding region’.

NB It seems apparent that a simple numerical value

for the mean angle of friction, is inadequate when at-

tempting to completely describe the frictional circum-

stances on the rake face.

In Fig. 182, is schematically depicted the ‘frictional

model’ purported by Zorev (1963). Here, Zorev sug-

gested that the normal stress distribution (‘σ

f

’) on the

tool’s rake face, could be represented by the following

simple expression:

σ

f

= qx

y

(iv)

80 ‘Sticking region’ at the tool/chip interface is oen termed the

‘stagnation zone’ , but in this case it appears on the formed/

sheared chip – depicted in Fig. 184 (top). Here, is shown a

magnied and etched view of a quick-stop for an insert cut-

ting carbon steel at 150 m min

–1

. A ‘stagnation zone’ is present,

that follows the insert’s prole, with ‘soened’ workpiece ma-

terial protecting the tool, by a sticking/sliding action. A ‘ow

zone’ occurs aer ‘shear plane’ , visibly dividing undeformed/

deformed material.

Where:

‘x’ = Distance along the rake face – from the

position where the chip losses contact with the tool’s

face,

‘q’ and ‘y’ = are constants.

e maximum normal stress ‘σ

fmax

’ occurs when ‘x’

equals ‘l

f

’ , so:

σ

fmax

= ql

f

y

or, transposing with respect to ‘q’:

q = σ

fmax

l

f

–y

(v).

Substituting for ‘q’ in equation (iv), we get:

σ

f

= σ

fmax

(x/l

f

)

y

(vi)

us, in the ‘sliding region’ , ranging from: x=0 to

x = l

f

– l

st

the coecient of friction ‘µ’ is constant and,

the distribution of shear stress ‘τ

f

’ along this region, is

represented by:

τ

f

= σ

f

µ = µ σ

fmax

(x/l

f

)

y

(vii).

So, in the ‘sticking region’ , the shear stress becomes a

maximum (‘τ

st

’), therefore from: x= l

f

– l

st

to x=l

f

:

τ

f

= τ

st

(viii).

By integrating equation (vi) to obtain the normal force

‘F

n

’ acting on the rake face (i.e. from Fig. 181), gives:

F

n

a

w

l

f

σ

f m ax

xl

f

y

dx

= σ

fmax

a

w

l

f/

1 + y (ix)

Where:

a

w

= Chip width (i.e. width of cut).

e friction force ‘F

f

’ on the tool’s rake face, is ob-

tained by:

F

f

a

w

τ

st

l

st

l

f

−l s t

µ σ

f m ax

xl

f

y

dx

= τ

st

a

w

l

st

+ µ σ

fmax

a

w

(l

f

– l

st

)

1+y/

l

f

y

(1+y) (x).

At position: ‘x = l

f

-l

st

’ , the normal stress ‘σ

f

’ is given by:

‘τ

st

/µ’. Moreover, from equation (vi), it is given by:

Chapter

σ

fmax

(l

f

-l

st

/l

f

)

y

erefore:

τ

st

= µ σ

fmax

(l

f

– l

st

/l

f

)

y

(xi).

By substituting equation (xi) in equation (x), it simpli-

es the expression for ‘F

f

’ , as follows:

F

f

= τ

st

a

w

l

st

+ τ

st

a

w

(l

f

– l

st

)/1+y (xii).

Hence, the mean coecient of friction on the rake face,

can now be found from both equations (ix) and (xii):

Mean friction angle =

F

f

/F

n

= τ

st/

σ

fmax

(1+yl

st

/l

f

) (xiii).

From equation (xi), the mean normal stress on therake

face (σ

fav

) is given by:

σ

fav

= F

n

/a

w

l

f

= σ

fmax

/1+y

us:

σ

fmax

= (1+y)σ

fav

(xiv).

Substituting for ‘σ

fmax

’ in equation (xiii), produces:

Mean friction angle = arctan{

τ

st

/σ

fav

[1+y(l

st

/l

f

)]} (xv).

However, from Zorev’s experimental work, he found

that the term:

τ

st

[1+y(l

st

/l

f

)]/1+y

will remain relatively constant for a specied work-

piece material, across a diverse range of unlubricated

cutting conditions and, as a result, the equation for the

mean friction angle becomes:

Mean friction angle = arctan

K/σ

fav

(xvi)

Where:

‘K’ = a constant.

What Zorev’s equation (xvi) indicates, is that the mean

friction angle is somewhat dependent on the mean

normal stress on the rake face, allowing the result to

explain the eect of modications in the working nor-

mal rake to that of the mean friction angle. us, as the

value of ‘α’ (i.e. working normal rake angle) increases,

the resultant component tool force being normal to

the rake face will decrease, so that the mean normal

stress will be reduced. Moreover, from equation (xvi),

an increase in ‘α’ could be expected to increase the

mean friction angle. is observation, has been con-

rmed by experimental work undertaken by Pugh

(1958), where an increase in ‘α’ was shown to result in

a a complementary increase with repect to the mean

friction angle – across an extensive range of workpiece

materials.

Since the passage of time when both of these ‘theo-

retical models’ for the mechanics of machining and the

frictional work produced by Ernst and Merchant and

that of Zorev, respectively, were produced. Consider-

able eort and progress has been made into advances in

our present understanding of: ‘slip-line eld modelling’ ,

‘thermal and frictional modelling of the cutting process’ ,

‘chip-ow analysis’ , ‘examination of the primary and

secondary shear zones’ , non-orthogonal (three-dimen-

sional) machining processes, advances in tool geometries

with their accompanying force and shear relationships

and the advent of applications to machining opera-

tions employing nite element analysis (FEA). If all of

these subjects and other not listed, were only concisely

mentioned, then the book would be of epic propor-

tions! defeating the object of reviewing cutting appli-

cations and trends in current practice. However, the

role of FEA, in both machining research and for the

‘dynamic and geometric modelling’ of applied residual

stresses occurring in both the tool and workpiece in

the anticipated cutting processes is worthy of discus-

sion. e topic of ‘computer simulation’ utilising an

FEA approach, has become of increasing importance

of late and several companies have produced products

in this eld. However, to obtain some degree of con-

sistency in the dialogue only one particular company’s

FEA product will now be described.

Computer Simulation of Machining

Processes – an Introduction

By the application of computers to simulate and anal-

yse machining processes, this provides tool manufac-

turers and users alike, assistance in improving machin-

ing eciency and will also predict the likely cutting

response to real-time machinability environments.

Most of the early two-dimensional simulation models

for the mechanics of machining, focussed attention on

shear-zone modelling. ese previous ‘models’ ignored

vital factors such as the frictional conditions along and

between the rake’s tool/chip interface, furthermore,

any potential work-hardening and temperature eects

in this vicinity were also tended to be disregarded.

Machinability and Surface Integrity

Over the last two decades, the application of nite ele-

ment analysis (FEA) to that of three-dimensional ma-

chining applications, has been successfully applied to

the cutting process. Major advantages of using FEA,

are its ability to accurately compute: complex material

property denitions; tool/chip interactions; non-linear

geometric boundary conditions – typied by the chip’s

surface; prediction of local variables – such as stress

and temperature distributions in the cutting locality.

Several approaches for the numerical modelling

of machining operations and in particular, for that of

metal cutting have been employed, such as ‘Lagrang-

ian and Eulerian’ techniques. In the former case which

has been utilised for over two decades, ‘Lagrang-

ian methods’ utilise the tracking of discrete material

points. Here, the technique is uses a predetermined

line of separation at the tool’s point, which propagates

a ctitious crack ahead of the tool’s tip. Previously, this

Figure 182. An idealised orthogonal cutting model of chip-tool friction, where:

• σ

f

= normal stress,

• τ

f

= shear stress,

• τ

st

= shear strength of chip material in the sticking region,

• I

f

= chip-tool contact,

• I

st

= length of sticking region.

[Source: Zorev, 1963]

.

Chapter

routine precluded the resolution of the cutting edge

radius and an accurate resolution of the secondary

shear zone – due to severe mesh distortion. In an at-

tempt to alleviate any form of element mesh distortion

‘adaptive remeshing techniques’ have been employed

to resolve the tool’s cutting edge radius. Whereas the

‘Eulerian approach’ tracks volumes rather than mate-

rial particles, having the advantage of not needing to

rezone any distorted meshes. Moreover the ‘Eulerian

technique’ , requires ‘steady-state free-surface tracking

algorithms’ and relied upon a particular bur unrea-

sonable assumption that a uniform chip thickness oc-

curred, further this method precluded the modelling

of either a segmented chip formation, or that of the

milling process. e former technique of a ‘Lagrangian

FEA machining model’ will be reviewed (Fig. 183), as it

has the integrating ability to achieve ‘adaptive remesh-

ing’ with explicit dynamics and tightly coupled tran-

sient thermal analysis, allowing it to ‘model’ the com-

plex interactions between the cutting tool’s geometry

and that of the workpiece.

Lagrangian FEA Simulation

Machining Modelling

In Fig. 183, just a few images of the Lagrangian FEA

machining model are depicted for several applica-

tions of machining operations. is simulation mod-

elling technique contains a tightly coupled thermo-

mechanical material response capability, this being a

vital factor for any elevated temperatures that occur

at the tool/chip interface, furthermore, having a fully

adaptive mesh generation ability. Hence, the material

modelling facility forms an intergral part when at-

tempting to predict the workpiece’s material behav-

iour, under high strain and increased stress condi-

tions. is advanced modelling capability ensures the

accurate capture of any strain-hardening, or thermal

soening eects coupled to rate sensitivity properties,

for a given set of material conditions. Many of today’s

ferrous and non-ferrous materials, together with ‘ex-

otic materials’ such as nickel and titanium alloys can

also be successfully simulated, across a diverse range

of single- and multi-point cutting tools (e.g. turning,

milling, drilling, broaching, sawing, etc.).

Machining Simulation – Validation

Not only can simulation techniques of the type shown

in Fig. 183 be utilised for workpiece material machin-

ing modelling: work-hardening; thermal-soening

eects; machining-induced residual stresses; induced

temperature eects and heat-ow analyses with the

‘adaptive’ ‘Lagrangian FEA machining model’. e

‘model’ can also reasonably accurately predict: both

two- and three-dimensional cutting force magnitudes.

Invariably, the individual cutting force components

can be closely validated to actual machining working

practice, the same can also be said for a comparison

of a ‘dynamically-modelled chip’ to that of an actual

chip’s morphology – including both its chip-curling

tendency and any chip segmentation occurring. ese

validated simulation capabilities enable the cutting

process to be improved, by using the:

•

Force and temperature information – to reduce

overall production cycle times,

•

Temperature and thermal eects – can be utilised

to improve tool life and part quality,

•

Tool wear analysis – predicts the eects of tool

ank wear and how this wear land inuences sub-

sequent: temperatures, pressures and forces,

•

Chatter and vibration prediction – indicating the

onset and magnitude of these unwanted eects,

•

Residual stress information – helps alleviate poten-

tial machined component fatigue and aids in part

deformation analysis.

NB e inuence that tool coatings have on the

dynamic machining eciency can also be reviewed,

plus the capability to customise the tooling with

chip-breakers to improve chip-curl, or chip evacu-

ation abilities.

Computer machining simulation of the type illus-

trated in Fig. 183, can be integrated into an overall

CAD/CAM package, enabling a range of signicant

advantages to accrue, without having to operate a

costly and time-consuming task of undertaking an

extensive machinability trial. is o-line machining

simulation facility, allows: realistic cycle-time calcula-

tions including cut-and non-cut timings; visualisation

of tool paths to high-light and then avoid any localised

‘power-spikes’ occurring during a machining opera-

tion and many other useful production features.

e use of a dynamic FEA machining simulation

package similar to the one mentioned and illustrated

in Fig. 183, adds a scientic element to the understand-

ing of the overall machinability of specic workpiece

materials and associated tooling. Such machining

simulation oers not only a visual interpretation to

Machinability and Surface Integrity

Figure 183. Simulated machining processes. [Courtesy of Third Wave Advant Edge].

Chapter