Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_12 pptx

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (1.29 MB, 9 trang )

tial stress concentration location. Furthermore, cra-

ters and pits normally exhibit shallow depth-to-width

ratios and are normally only present a problem from

the ‘cosmetic appearance’. Cracks in the surface are

normally classied as either ‘micro-’ , or ‘macro-cracks’ ,

with these cracks having depth-to-width ratios of >4,

typically they can promote:

•

Reductions in: mechanical strength; fatigue life;

plus creep resistance

87

,

•

Increases in the susceptibility to stress-corrosion

88

,

•

Probability increase in a surface material break-out

and generation of debris,

•

Surface delamination and fatigue.

Cracks may be considered as either separations, or

narrow ruptures that interrupt the surface continuity

and normally include sharp edges, severe directional

changes, or both. Macro-cracks can usually be visu-

ally inspected with the naked eye, conversely micro-

cracks obviously require microscopic examination.

Oen these cracks are complex metallurgical interac-

tions which are exacerbated by an ‘abusive’ machine

regime, leading to an unacceptable surface condition.

A crack’s origin can be the result of several multifari-

ous phenomena, typically they can be an inter-granu-

lar attack that might be degraded by surface dissolu-

tion, via chemical processes. Whenever preferential

intergrannular attack takes place, it can additionally

promote a grain boundary network of micro-cracks

that can extend beneath the surface, tracing-out and

following the underlying grain boundaries. Even mi-

cro-cracks should not be ignored, as they can aect

the component’s functional performance, because they

act as a potential source for macoscopic crack fatigue.

Hence, once a crack has been generated it cannot be

successfully resealed, owing to subsequent contamina-

tion and continuous chemical reactions. In fact, the

process of fatigue failure (i.e. see Fig. 190 bottom-right

for photomicrographs of a cranksha’s fatigue failure

87 ‘Creep’ , is: ‘e time-dependent plastic deformation of materials

that occur under constant load at relatively high temperatures

and low stresses’.

88 ‘Stress-corrosion cracking’ (SCC), is: A combined mechanical

and chemical failure mechanism in which a non-cyclic tensile

stress [below the yield strength] leads to the initiation and prop-

agation of fracture in a relatively mild chemical environment’.

mechanism) can be characterised by three discrete

steps:

1.

Crack initiation – where a minute crack forms at a

particular site, such where a high stress concentra-

tion occurs,

2.

Crack propagation – during which time at which

the crack incrementally advances with each stress

cycle

89

,

3.

Final failure – rapidly occurs, once the advanc-

ing crack has reached a critical size being close to

‘speed of sound’: Mach 1 – and is a catastrophic

failure mechanism.

White-Layers

e so-called ‘white-layers’

90

that can appear when

‘abusive machining’ certain ferrous work-hardening

materials, are a result of microstructural and metal-

lurgical alterations to the machined sub-surface layers

of a workpiece (Fig. 189c). is undesirable and un-

wanted ‘white-layer’ condition is visually apparent (i.e.

when a taper-section through the machined surface

has been taken), as it resists standard etchants and the

consequence is a visible ‘white-layer’ – when viewed

under an optical microscope.

89 ‘Striations’ , (also known as ‘Beach-’ , or ‘Clamshell-marks’

– see Fig. 190bottom-right), are concentric ridges that expand

away from the initial crack site(s), frequently appearing in a

circular, or as a semi-circular radial pattern.

NB is ‘striation eect’ is analogous to that of a stone be-

ing dropped into a still pond – with the stone entry being the

equivalent of the initial crack site, while the radial/circular

waves generated, are akin to the cumulating concentric stress

ridges – until they intersect with the pond’s bank [ie free-sur-

face].

90

‘White-layers’ , are a metallurgically unstable sub-surfaces

exhibiting a very hard localised state, with a supplementary

heat-aected zone (HAZ) beneath it, which is soer than the

overall bulk hardness of the workpiece’s matrix – hence, this

metallurgical instability. ‘White-layers, can be classied de-

pending upon whether it resulted from: mechanical; chemi-

cal; or thermal events, which also directly relates to machined

workpiece factors such as: strain; strain-rate; heating/cooling

rates; plus environmental conditions.

NB In the past, ‘white-layers’ were known by several terms,

such as: ‘white-phases’; ‘white-etchings’; ‘hard-etchings’; etc.

– depending upon the variety and type of ‘white-layering’ pro-

duction.

Chapter

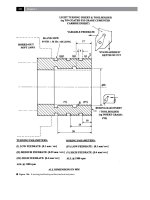

Figure 189. The inuence of the cutting edge’s condition on the resultant machined surface integrity .

Machinability and Surface Integrity

In Fig. 189c, a ‘white-layer’ (i.e. for this ferrous

drilled part, being a localised untempered martensitic

phase of 63 H

Rc

91

) exists beneath the recast and rede-

posited layer, in this case produced by a ‘dull’ drill’s

cutting lips and margins. Due to the fact that the recast

layer (i.e. heat-aected zone – HAZ) has a similar met-

allurgy to that of the ‘white-layer’ , with the delineation

of these ‘white-layers’ regions and their accompany-

ing HAZ’s are not clearly dened. is latter HAZ is a

complex metallurgical condition, comprising of some:

untempered martensite (UTM); over-tempered mar-

tensite (OTM), while beneath these layers, the bulk

substrate material remains unaected. e thickness

of these ‘white-layer’ zones is strongly inuenced by

both the actual plastic deformation created here and,

to a lesser degree, by the thermal inuence of the pas-

sage of the tool’s edge over the machined surface as

heat penetrates into the locality of the component’s

surface. Probably the worst ‘abusive machining’ condi-

tions that can exist, are when drilling holes in work-

hardening materials having long length-to-diameter

ratios (i.e. L/D ratios of >12:1) with inadequate cool-

ant supply, creating high levels of friction, this condi-

tion being exacerbated by an ineciency produced by

a ‘dulled’ drill’s cutting lips.

Virtually all tooling even the most sharp – the no-

table exception here being monolithic faceted natu-

ral diamond cutting edges, have a nite tip radius of

≈8 µm (i.e. see Fig. 184 – high-lighting the tool tip

‘rounding eect‘), this results in increased forces and

tool wear, which can transform the surface metallurgy

by thermo-mechanical generation. e case has al-

ready been made concerning the fact that machining

processes impart residual stresses into the surface lay-

ers, as indicated in the schematically-represented mill-

ing conditions shown in Fig. 190 and graphically, in

Fig. 191 for a series of milling operations where preset

‘wear lands’ were generated on the cutter’s teeth prior

to workpiece machining. is latter case (Fig. 191) of

articially-inducing a controlled ‘wear land’ onto the

face-milling cutter’s individual tooth (i.e. with the other

teeth removed, hence, acting as ‘Fly-cutter‘), then aer

91 By way of comparison of this untempered martensitic ‘white-

layer’ phase, a conventional high-speed steel (HSS) milling

cutter’s teeth would have had a maximum hardness aer heat-

treatment of 62 H

Rc

, which clearly signies the true local hard-

ness of these ‘white-layers’.

several milling passes plotting the residual stress levels

from the surface and into the 4340 steel workpiece’s

substrate under standardised cutting data (i.e the steel

specimens having previously been quenched and tem-

pered to a bulk hardness of 52 H

Rc

). Hence, the eect

of these dierent induced tool wear rates and their

inuence in terms of their respective magnitudes and

depths, can clearly be seen. Even when the cutting edge

has ‘sharp tooth’ , a certain degree of tensile residual

stress was apparent in the immediate surface region.

Here, directly under this tensile stress zone, the stress

concentration changed to one of compression (i.e. to

a depth of ≈50 µm). As each milling cutter tooth ank

became steadily more worn, the substrate compression

layer also increased in magnitude, which could lead to

considerable workpiece distortion, once the clamping

forces had been released – particularly if only one-side

of the part was milled (i.e. see Fig. 186b).

If the forces involved in the machining process ex-

ceed the ow stress, plastic deformation occurs and

the structure is deformed. In the case o ductile materi-

als, the plastic ow can create a range of degenerative

surface topography characteristics, such as: burrs; laps;

BUE residue; plus other unwanted debris deposits. If

this deformation becomes severe as a result of exces-

sive plastic ow, any grains adjacent to the surface

may become fragmented to such an extent that little,

or no metallic structure can be metallographically re-

solved, therefore ‘white-layering’ will result. Normally,

a ‘white-layer’ region extends to quite a small depth

beneath the surface, in the region of 10 to 100 µm, de

-

pending upon the severity of the ‘abusive regime’ of

surface generation. Considering Fig. 191 once again,

as can be seen, the residual stress is indicated along the

vertical axis, here instead, it is alternatively possible

to superimpose a micro-hardness axis – see Fig. 191

circular inset graph. A note of care is required when

changing the vertical axis from residual stress to that

of micro-hardness, as they are two distinct quantita-

tive values. As mentioned the hardness prole closely

approximates that of the residual stress curve, however

in the latter case, instead of tensile stress at the in the

surface region, the sub-surface layer could equally be

compressive in nature.

‘White-layers’ must be avoided under all occasions,

because of the unstable metallurgical condition, com-

pounded by the fact that the these regions act as po-

tential stress-raisers for any critically-engineered com-

ponent and can lead to premature failure, or at worse,

catastrophic failure in-service.

Chapter

Figure 190. Typical fatigue characteristics within the component’s surface region, being inuenced by the mode of

milling: up-cut or down-cut

.

Machinability and Surface Integrity

Figure 191. Comparison of the residual stresses in some milled surfaces, obtained with articially-

induced tooth wear lands. [After: Field & Kahles, 1971]

.

Chapter

Altered Material Layers

So that an impression of the altered material layers

(AMLs) that can occur for a diverse range of: surface

and sub-surface topographical features; dierent met-

allurgical processes; mechanical applications and uses;

Table 13 has been constructed, to high-light their par-

ticular inuence on functional performance. In the

majority of cases given in Table 13, the inuence of

these sub-surface defects tends to be of signicance,

especially with respect to an ‘abusive regime’ produc-

ing a machined ‘white-layer’. In some instances, the ‘al-

tered material zone’ (AMZ), can aect component in-

service performance in a variety of ways. For example,

where thein-service tribological situations produce ei-

ther re-deposited, or recast layers in the surface region,

it has been known that such defects will inuence wear

and aect reliability. is oen undetected sub-surface

Table 13. The inuence of substrate features on function

Surface integrity: sub-surface features

Function: Metallurgy Deformation Deposits Stress

UTM

or

WL

OTM

rev

Aust IGA WL Plastic

defn

Burrs Cracks Tears

and

laps

Tool

frags

Redp

matl

Res

stress

Wear

Strength

Chemical

attack

Fatigue

Magnetism

Bearings

Seals

Friction

Forming

Bonding and

adhesion

Key: : strong inuence on function; : some inuence on function; : possible inuence on function

Abbreviations: UTM: untempered martensite; OTM: over-tempered martensite; Aust rev: austenitic reversion; IGA: intergranular attack; WL:

white-layer; Plast defn: plastic deformation; Tool frags: tool fragments; Redp matl: re-deposited material; Res stress: residual stress.

[After: Griths et al., 2001]

.

Machinability and Surface Integrity

condition degrades the functional performance, due

to the fact that they are the product of hard, brittle and

unstable layers, with tensile residual stresses present.

ese factors, combined with an acute alteration to the

bulk substrate, are likely to ‘spall’ (i.e. delaminate and

break-away). Conversely, if a sub-surface feature pro-

duces severe plastic deformation, evidence has shown

in particular for the die and tool industry, that some

dies benet from increased life due to enhanced abra-

sion resistance.

From Table 13, the design engineer can see that by

simply selecting a production process without an inti-

mate knowledge of how components are to be manu-

factured will inevitably aect the subsequent part’s

in-service application. Moreover, due regard must be

given to the machined workpiece’s potential sub-sur-

face state, as this condition will inexorably lead to

problems in terms of potential impairment of its ser-

vicing needs and reliability.

Surface integrity Manipulation – Burnishing

Par t’s for Surface Improvement

Burnishing and in particular roller burnishing (Fig.

192) is a very fast production technique for improving

both the nish and dimensional accuracy of either an

internal, or external surface, by pressure rolling with-

out removal of workpiece material. Roller burnishing

is a cold-working process, that produces a ne surface

texture by the application of the planetary rotation of

hardened rolls over the previously machined bored, or

turned surface (Fig. 192c). Moreover, unlike the pri-

mary forming process of cold-rolling which normally

produces large sectional changes, roller burnishing

involves cold-working just the surface layers of the

workpiece, to improve the surface structure.

Roller burnishing tooling (Fig.192a) can be used

for minute diameter adjustment down to 25 µm, allow

-

ing component dimensional accuracies of ±0.006 mm

to be obtained. e action of roller burnishing causes

plastic deformation of the workpiece’s previously ma-

chined surface. At a given depth below the burnished

surface, the material is elastically deformed and at-

tempts to spring back. is action, gives rise to com-

pressive stresses at the surface and tensile stresses in

the elastically-deformed zone. is complex stress

interaction increases the resistance of the material to

fatigue failure, because any external forces must rstly

overcome these residual stresses.

e potential for cracking that can occur due to

the interaction between the static and tensile stresses

in the metal and a corrosive medium is termed ‘stress

corrosion cracking’. During roller burnishing, these

tensile stresses are eliminated when the burnising

tool compresses the workpiece surface. Likewise, any

pits, scratches and porosities in the surface, which

might otherwise collect reactive substances and con-

taminants, are eliminated, hence, roller burnishing in-

creases the corrosion resistance of the material.

Crystalline materials typied by their metal lattices,

are never completely without aws. e atomic lattice

will always contain built-in irregularities of various

types. ese so-called atomic dislocations reduce the

strength of the material, as less force is necessary to

alter the atomic lattice. Dislocation motion of atoms

is a complex subject, which goes beyond the scope of

the present text, however, it can be said that upon the

application of an external load (i.e. burnishing tool-

ing), because the lattice is invariably not perfect, less

force is necessary to defrom the structure. Here, an at-

tempt is made to inhibit the movement of dislocations

by means of diering hardening procedures. Cold-

working increases the number of dislocations and one

would expect the material to become soer, but in fact,

the opposite eect transpires. is increased hardness

takes place, because there are so many dislocations as

a result of cold-working, that they prevent and restrict

each other’s motion, as a result the surface hardens.

is is what occurs in roller burnishing, as the material

is displaced and the net result is that it becomes both

harder and stronger – due to dislocation obstructions.

By way of a cautionary note, both Rockwell and

Brinell hardness testing methods cannot realistically

obtain surface hardnesses readings satisfactorily,

therefore it is recommended that the Knoop test (Fig.

192b) should be used, then converted with a suitable

‘hardness comparison chart’ – see the appropriate table

in Appendix 12.

is completes a brief synopsis of a discussion on

certain aspects of both machinability and surface in-

tegrity, which hopefully conveys the importance of the

machining activities and the resulting machined sur-

face condition. Considerably more space could have

been devoted to a comprehensive review of these top-

ics, but space was limited, this is the reason for a rea-

sonably comprehensive list of references – for a more

in-depth discriminating reading on these important

machining and related issues.

Chapter

Figure 192. Roller burnishing improves the metallurgical properties of the previously machined surface. [Courtesy of Sand-

vik Coromant]

.

Machinability and Surface Integrity

References

Journals and Conference Papers

Albrecht, P. New Developments in the eory of Metal-cut-

ting Process – Part 1: e Ploughing Process in Metal Cut-

ting. ASME J. of Engg. For Ind., Vol.82, 348–358, 1960.

Bayoumi, A.e., Xie, Q. and Hamdan, M.N. Eect of Cutting

Conditions on Dynamic Properties and Surface Integrity

of Work Material. WEAR, Vol. 146, 301–312, 1991.

Bellows, G., Field, M. and Kohls, J.B. Inuence of Material

and its Metallurgical State on Surface Integrity. In: Inu-

ence of Metallurgy on Machinability, ASM Pub. (Ohio),

272–295, 1975.

Bonifácio, M.E.R. and Diniz, A.E. Correlating Tool Wear,

Tool Life, Surface Roughness and Tool vibration in Fin-

ish turning with Coated Carbide Tools. Wear, Vol. 173,

137–144, 1994.

Boothroyd, G. Temperatures in Orthogonal Metal Cutting.

Proc. of IME., Vol. 177, 789, 1963.

Bridgman, P.W. In: Phys. Rev., Vol. 48, 825, 1935; ibid.

Proc. American Acad. Arts Sci., Vol. 71, 386, 1937; ibid,

J. Appl. Phys., Vol. 8(5), 328, 1937; ibid, J. Appl. Phys.

Vol.14(6), 273, 1943; and ibid, e Physics of High Pres-

sure, G. Bell & Sons Ltd. (London), 1949.

Brinksmeier, E., Cammett, J.T., König, W., Leskovar, P.,

Peters, J. and Tönsho, H.K. Residual Stresses: Measure-

ment and Causes in Machining Processes. Annals of the

CIRP, Vol. 31(2), 1982.

Chou, K.Y. and Evans, C.J. White Layers and ermal Mod-

elling of Hard Turned Surfaces. Int. J. of Mach. Tools

& Manufact., Vol. 39, 1863–1881, 1999.

Dagnell, J. Machinability Test by a Drilling Method. Annals

of the C.I.R.P., Vol. XV, 301–308, 1967.

Dillion, O.W., DeAngelis, R.J., Lu, W.Y., Gunasekera, J.S.

and Deno, J.A. e Eects of Temperature on the Ma-

chining of Metals. J. Mater. Shaping Technol., Vol. 8,

23–29, 1990.

Dornfeld, D.A. Monitoring of the Machining Process by

Means of Acoustic Emission Sensors. In: Acoustic Emis-

sion: Current Practice and Future Directions, ASTM

STP 1077, W. Sachse, J. Roget and K. Yamaguchi, ASTM

(Philadelphia), 328–344, 1991.

Dornfeld, D.A. König, W. and Ketteler. Aktueller Stand

von Werkzeug- und Prozess-überwachung bei der Zer-

spanung. Neuentwicklungen in der Zerspantechhnologie.

Proc. Of the CIRP/VDI Conf., Düsseldorf, 363–376,

1993.

El-Wahib, A.I. and Kishawy, H.A. A New Method to Im-

prove the Surface Quality During CNC Machining. Int. J.

Prod. Res., Vol. 38(16), 3711–3723, 2000.

Eyada, O.S. Reliability of Cutting Forces in Machinability

Evaluation. Proc. of FAIM’92, CRC Press, Inc. (Florida),

937–946, 1992.

Ernst, H. and Merchant, M.E. Chip Formation, Friction and

High Quality Machined Surfaces. In: Surface Treatment

of Metals, ASM Pub. (NY), Vol. 29, 299, 1941.

Fathailal, M., Danai, K. and Barber, G. Eect of Flank

Wear on the Topography of Machined Surfaes. Tribology

Trans., Vol. 36(4), 693–699, 1993.

Feather, J.J. Using Value Analysis to Target Customer Service

Process Improvements. Ind. Engg. Solutions, 33–39, May

1998

Fick, A.E. [Laws of Diusion], Annals of Physics (Leipzig,

Germany), Vol. 170, 59, 1855.

Field, M. and Kahles, J.F. Review of Surface Integrity of

Machined Components. Annals of the CIRP, Vol. 20(2),

153–163, 1971.

Gorzkowski, E. and Sathyanarayanan, E. Machinability.

Cutting Tool Engg., 54–58, Feb., 1999.

Griths, B.J. Problems in Measuring the Topography of Ma-

chined Surfaces Produced by Plastic Deformation Mecha-

nisms. WEAR, Vol. 109, 195–205, 1986.

Griths, B.J. Manufacturing Surface Design and Monitor-

ing for Performance. Surface Technology, Vol. 1, 61–69,

1988.

Griths, B.J. and Furze, D.C. Tribological Advantages of

White Layers Produced by Machining. Tans. of ASME

– J. of Tribology, Vol. 109, 338–342, April 1987.

Griths, B.J. Deciencies in Surface Specications. Proc. of

Lamdamap III, Computational Mechanics, 465–474,

1997.

Griths, B.J. Mechanisms of White Layer Generation with

Reference to Machining and Deformation Processes.

Trans. of ASME – J. of Tribology, Vol. 109, 525–530,

July, 1987.

Gugger, M. Getting to the Bottom of Chatter. Cutting Tool

Engg., 54–60, April, 2000.

Hirao, M. Determining Temperature Distribution on Flank

Face of Cutting Tool. J. Mater. Shaping Technol., Vol. 6,

143–148, 1989.

Kackar, R.N. O-line Quality Control Parameter Design

and the Taguchi Method. J. of Quality Tech., Vol. 17(4),

176–188, Oct., 1985.

Kasahara, N., Sato, H. and Tani, Y. Phase Characteristics

of Self-excited Chatter in Cutting. J. of Engg, for Ind.,

393–399, Vol. 114, Nov. 1992.

Kennedy, B. Calming Chatter – Strategies for Minimising

Tool Chatter. Cutting Tool Engg., 28–35, July, 2004.

Kirchheim, A., Schaner, G. and Wolfer, P. Piezoelektrische

Sensoren zur kombinierten Messung von Kräen und

Acoustic Emission für die Prozessüberwachung. Int.

CIRP/VDI Konferenz: Überwachung von Zerspan- und

Umformprozessen, Düsseldorf, 30–31.3, 1995.

Kohls, J.B. Metallurgical Damage in Drilling and Hole Qual-

ity. In: Inuence of Metallurgy on Hole Making Opera-

tions, ASM Pub. (Ohio), 145–158, 1978.

Chapter