HYUNDAI AERO TOWN D6DA 2010 hệ THỐNG PHANH ANTI LOCK BRACKE general

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (367.38 KB, 17 trang )

General

ABS Function

Under rapid braking or sloppy road condition by rain or snow, braking a vehicle in running is apt

to generate skid condition. The skid may decrease braking force to increase braking distance,

generate spin by traverse slipping, and/or disable steering control, resulting to an accident.

Therefore the ABS system is designed to prevent from wheel locking and slip upon braking for

ensuring :

1 Stability,

.

2.Steer ability, and

3 Optimum braking power and stopping distance.

. Skid : A vehicle may slip to move without wheel rotation upon braking.

Slip rate (λ)

Upon braking a vehicle which is running, slip rate changes from 0 to 100% until the wheels are

locked and the vehicle stops completely. The slip rate l may be indicated as the below :

λ = Vehicle speed - Wheel speed / Vehicle speed × 100(%)

The slip rate (λ) and the surface friction coefficient (μB) may be correlated as the illustration.

The slip rate (λ) at the max.mB differs by the road condition but the max. range is approx,

8~30%. The cornering force (transversely slip preventing force) decreases with increasing slip

rate. Once wheels are locked, surface friction coefficient μB decreases and slip friction

coefficient μS becomes to '0', and then wheels are easy to slip.

In fact locked rear wheels generate spinning and locked front wheels disables steer ability. The

ABS system controls braking force to maintain the slip rate in the range of 8~30%, in order to

generate max. surface friction coefficient, control slip friction coefficient at higher range, and

provide stability and steer ability.

ABS Effect

The ABS system provides stable braking under extreme condition. Even braking rapidly on

frozen or snowy road, wheels are not locked and maintain max. friction with the road surface to

provide optimum braking distance. Restricting the pressure in the chamber locked at the wheel

side on the road surface, the system ensures straight forward motion. The driver may acquire

correct alignment of the vehicle by adjusting the steering wheel only a little.

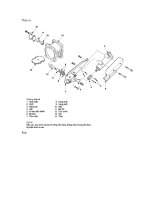

ABS configuration

Full air brake

Air over hydraulic brake

Principle

Parts functions

1 Wheel speed sensor

. The 4-channel ABS uses four wheel speed sensors. The sensor consists of a permanent magnet

connected to metal rod, around which a coil has been wound. A pulse wheel mounted to the

hub induces an alternating voltage in the sensor coil. The frequency of the alternating voltage

is managed signal in the control unit.

2.ABS/ASR control unit

The ABS/ASR control unit is designed in digital type and possess dual microprocessors, with

the following four features:

(1)Input stage

The unit checks the wheel speed signal

(2)Computer

The computer calculates the brake slip/traction and wheel deceleration/wheel acceleration

control signal, and energize the output stage when wheels are about to be locked or spin.

(3)Output stage

The unit energizes interface and axle weight distribution unit for controlling the pressure

control valve, the solenoid valve, and the engine.

(4)Power supply

The unit supplies stable voltage for the control unit operation. The built-in protective

device prevents electrical interference from applying to the vehicle electrical circuit.

3 Pressure control valve (1 channel)

. Each wheel is not controlled by a 1 channel control valve. The pressure control valve includes

two diaphragm type valves (for pressure modulation, and for outlet) that are guided and

controlled by the solenoid valves. Upon normal braking, compressed air freely pass through the

pressure control valve to the brake cylinder. If one of wheels is about to be locked, the

ABS/ASR control unit energizes both solenoid valves to lower the pressure in the brake

cylinder. The pressure modulation valve operates to modulate the pressure. When the pressure

is rising no current flows in the two solenoid valves.

4.Solenoid valve

The solenoid valves are connected with two 3/2 solenoid valves that are pilot-controlled. When

wheel's are about to spin, the valve energizes the axle brake cylinder driven by compressed air.

Two control plungers are controlled by the solenoid valves.

When current is interrupted, power supply 1 is close and the cylinder connections are open

outwards.

ABS control

When the drive press the brake pedal, the pressure is supplied to the brake cylinder (or air

chamber), and result to wheel deceleration. When the brake slip is lower than the ABS system

reaction limit value, the braking power is not controlled. The ABS/ASR valve rises. In order to

provide the most proper pressure in the brake cylinder, the pressure decreases, is maintained, or

increases in accordance with friction coefficient between tires, road surface, and vehicle steering.

The illustration 6 indicates the ABS control feature on wheels upon braking. At time t1, the

pressure in the brake cylinder increases and the wheel speed decreases. At time t2, the wheel

deceleration and the slip rate increase above the limit, and the wheel is about to be locked. With

closing the pressure modulation valve and opening the exhaust valve, the pressure in the brake

cylinder increases until the wheel speed increases again at time t3. Closing the exhaust valve, the

pressure is maintained at a certain level to time t4. Then the slip value l =0 approximately, and

the wheel acceleration reached the value that may raise the pressure again. Then instantly

opening and closing the pressure modulation valve, the pressure becomes pulse-up until time t5.

The wheel deceleration and slip is higher than the limit again, and the pressure rise again. The

control cycle repeats until the vehicle stops actually.

Yaw moment on the front axle

When the friction coefficients are significantly different between right and left wheels (for

example when the road is frozen at outer side), corrective control feature is applied to the front

axle accommodating between short braking distance and steering corrective value. Constraining

pressure rising and braking force on wheels, the yaw moment is restricted within the range that

vehicle control is possible under rapid braking condition.

Friction force between tire and surface

Friction force between tires and road surface when other conditions are same, friction forces

between tires and road surfaces are virtually same for starting and braking conditions. Friction

force measurement (friction coefficient) differs by road condition, weather condition, tread type,

and especially braking and wheel slip. (Refer to illustration 7). In usual, braking motive force is

within the stable area of slip curve. In general rapid braking increases brake slip and decrease

friction force. With higher brake slip, wheels have lower traverse force for stability and steer

ability of the vehicle.

The ABS system is designed primarily for stability and steer ability of the vehicle. Friction force

on running as well as on braking relies particularly on slip between tires and road surfaces. With

higher wheel slip, traction and running stability decreases. With lowest wheel friction,

differential function provides driving power.

performance when there are faults present

Speed sensor

System configuration : Air over hydraulic brake

ABS control

Failure

WL

Front left

Front

right

Front left speed sensor

NO¹

IC

IC

IC

ON

Front right speed sensor

IC

NO¹

IC

IC

ON

Rear left speed sensor

SL

SL

NO

IC

ON

Rear right speed sensor

SL

SL

IC

NO

ON

Mixed up speed sensors

NO

NO

NO

NO

ON

Tire size, alignment error

NO

NO

NO

NO

ON

Two speed sensor errors or one

speed sensor error and one PMV

error

NO

NO

NO

NO

ON

IC : individual control

Rear left Rear right

SL : Select low

WL : Warning lamp

1) Brake pressure is modulated according to behavior of not affected wheel.

System configuration : Full air brake

ABS control

Failure

WL

Front left

Front

right

Front left speed sensor

NO¹

IC¹

IC

IC

ON

Front right speed sensor

IC¹

NO¹

IC

IC

ON

Rear left speed sensor

MIC

MIC

NO

IC

ON

Rear right speed sensor

MIC

MIC

IC

NO

ON

Mixed up speed sensors

NO

NO

NO

NO

ON

Tire size, alignment error

NO

NO

NO

NO

ON

Two speed sensor errors or one

speed sensor error and one PMV

error

NO

NO

NO

NO

ON

Rear left Rear right

IC : individual control

SL : Select low

MIC : Modified individual control

1) MIC if affected wheel is on high m side.

PMV errors

System configuration : Full air brake

ABS control

Failure

WL

Front left

Front

right

Valve solenoid front left shorted

low or broken wire or valve ground

front left broken wire

NO

IC

IC

IC

ON

Valve solenoid front right shorted

IC

NO

IC

IC

ON

Rear left Rear right

low or broken wire or valve ground

front right broken wire

Valve solenoid rear left shorted low

or broken wire or valve ground rear

left broken wire

MIC

MIC

NO

IC

ON

Valve solenoid rear right shorted

low or broken wire or valve ground

rear right broken wire

MIC

MIC

IC

NO

ON

Any valve solenoid or valve ground

shorted high

NO

NO

NO

NO

ON

Valve ground shorted low

MIC

MIC

IC

IC

ON

Two valve error or one valve error

and one speed sensor error

NO

NO

NO

NO

ON

System configuration : Air over hydraulic brake

ABS control

Failure

WL

Front left

Front

right

Valve solenoid front left shorted

low or broken wire or valve ground

front left broken wire

NO

NO

IC

IC

ON

Valve solenoid front right shorted

low or broken wire or valve ground

front right broken wire

SL

SL

NO

IC

ON

Valve solenoid rear right shorted

low or broken wire or valve ground

rear right broken wire

SL

SL

IC

NO

ON

Any valve solenoid or valve ground

shorted high

NO

NO

NO

NO

ON

Valve ground shorted low

SL

SL

IC

IC

ON

Two valve error or one valve error

and one speed sensor error

NO

NO

NO

NO

ON

Rear left Rear right

Power supply errors

ABS control

Failure

Front left

Front

Rear left Rear right

WL

right

GND shorted high or broken wire

NO

NO

NO

NO

ON

U_PMV or U_ECU over voltage or

low voltage¹

NO

NO

NO

NO

ON

U_PMV or U_ECU broken wire

NO

NO

NO

NO

ON

1 : Errors are reversible (can reast) provided they do not occur during ABS cycles.

Miscellaneous errors

ABS control

Failure

WL

Front left

Front

right

NO

NO

NO

NO

ON

Internal relay always ON

YES¹

YES¹

YES¹

YES¹

ON

RET shorted high or shorted low or

broken wire

YES¹

YES¹

YES¹

YES¹

ON

CAN interface bus off

YES¹

YES¹

YES¹

YES¹

ON

CAN interface error on message

ERC1

YES¹

YES¹

YES¹

YES¹

ON

Internal ECU failure or internal

relay switch failure

Safety monitoring

Rear left Rear right

1 Safety monitoring

. The ABS system satisfies highest safety and reliability requirements. Prior to starting the

vehicle, microcomputers perform self-diagnosis and check other computers, and then monitor

wheel spin sensor, pressure modulation valve, wiring harness, and the whole ABS system.

Finding a failure the ABS system becomes wholly or partly inoperable and the warning lamp

comes on. The service brake system is still operable.

2.Self-diagnostic feature

In addition to the safety monitoring system, the self-diagnostic feature built in the ABS control

unit enables to remove the failure immediately and safely. Upon failure detection by the ABS

control unit, the failure code is stored in the computer that may be read later at a service shop.

Then temporary failures including poor contraction at plug connection may be found and

eliminated soonest.

3 How to read the failure code

. Failure codes may be read using a Hi-scan and self-diagnosis by blink signals of the lamp.

Self-diagnosis on a vehicle

1 ABS lamp

. When a problem occurs in using the ABS system, the red ABS lamp comes on for warning in order to

facilitate finding the trouble area by self-diagnosis.

In normal condition, the ABS lamp comes on upon switching the battery power on and extinguished upon

starting the vehicle and during running. If a trouble occurs in the ABS system during running, the ABS lamp

comes on even or running.

2.Diagnostic method

The blink code device reads out error codes of 16 systems that are stored in the ECU system

configuration and error memory. The device checks the brake signal, as well.

The blink codes may be read using the ASR lamp, and troubles read with the self-diagnostic

button may be identified using the blink code table.

3 Blink code configuration

. In order to operate the blink code, keep the self-diagnostic button pressed for two seconds and then release it.

Pressing the button once it will indicate the system configuration and an error code. Press the self-diagnostic

button once again to read error codes.

The ASR lamp indicates an error code each time pressing the button.

After reading out all error codes stored in the memory using the blink codes, the last stored code may be read

continually.

Quitting self-diagnosis for 5minutes or more, or switching the starting key off and on again, the selfdiagnostic feature reads all information again from the beginning, the system configuration.

Each error code including the brake signal failure, includes three blocks.

The first block may be read at 100's digit, the second block at 10's digit, and the third block at 1's digit.

4.Failure memory erasion

Then ABS ECU will erase all error codes when the diagnostic push button is pressed during power on.

5.Safety measure

Upon ABS failure

Failed circuit

Operate as a non-ABS brake

Other circuits

ABS operation

At least the ABS system may operate just same as a non-ABS brake.

Hi-scan check

1 Turn the starting key off.

.

2.Connect a Hi-scan with the data link connector located under the low crash pad panel.

3 Turn the starting key on.

.

4.Using the Hi-scan, check DTCs.

5.Upon repairing or correcting the problem, turn the starting switch and clear stored error codes

using the clear key.

6 Disconnect the Hi-scan.

.