Automotive mechanics (volume II)(Part 4, chapter24) automatic transmission service

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (5.53 MB, 26 trang )

481-506_May 2chap 24

13/9/06

4:14 PM

Page 481

481

Chapter 24

Automatic transmission service

Maintenance

Checking and changing the fluid

Automatic transmission fluids

Fluid problems

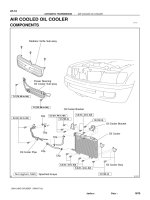

Extra cooling and filtering

Transmission adjustments

Brake band adjustments

Fault diagnosis and checks

Road testing

Diagnosing problems

Transmission overhaul

Transmission construction

Technical terms

Review questions

481-506_May 2chap 24

13/9/06

4:14 PM

Page 482

482 part four automatic transmissions and drive

There are many variations in the design of automatic

transmissions and transaxles, and this affects the

methods of dismantling and servicing. However, there

are some common servicing requirements and these

will be covered in this chapter. For particular

transmissions, reference to the detailed procedures in

the appropriate service manual will be necessary.

Checking and changing the fluid

The level of fluid in the transmission is checked with a

dipstick. The dipstick has full-level and low-level

marks and may have different levels marked for hot

and cold fluid (Figure 24.1).

Maintenance

Automatic transmissions and transaxles require a

regular check of the fluid level. They also need more

detailed service at regular intervals. This will vary with

different transmissions.

Some manufacturers specify service on a time

and kilometre basis, for example, each three years or

60 000 kilometres, others have only a time period.

However, all manufacturers state that service should be

carried out more frequently if the vehicle is operating

in adverse conditions. Where no definite service period

is specified, then it is reasonable to carry out a service

at every 50 000 kilometres. This would be for a

passenger vehicle with normal use.

An automatic transmission service could include

draining and replacing the fluid in the transmission and

converter, removing and cleaning the oil pan, cleaning

or replacing the filter, carrying out adjustments to the

bands and linkage and, finally, road testing the vehicle

to check performance.

Increased power and increased under-bonnet

temperatures mean that automatic transmission fluids

in modern motor vehicles are subjected to increasingly

severe operating conditions. Therefore, regular replacement of transmission fluid is now more important than

in the past.

Changing the transmission fluid will:

1. remove dirt, metal particles and condensation

2. remove fluid contaminants formed as a result of

high fluid temperatures

3. restore the correct balance of additives such as anticorrosives and detergent/dispersants.

Cleanliness

When working on an automatic transmission, cleanliness is essential. The transmission contains a large

number of valves, seals and passages, and any dirt or

foreign material introduced into the transmission will

cause malfunction and possible damage. The correct

type of fluid must be used, and all containers and dispensing equipment must be perfectly clean to prevent

contamination.

figure 24.1

Checking the level of the automatic transmission fluid MAZDA

The level of the fluid is checked while the engine is

idling and at normal operating temperature, and with

the selector lever in the drive or park position.

■ Unless the fluid level is checked by the recommended method, a false level will be indicated on

the dipstick.

Checking the fluid level

A typical method for checking the fluid level is as

follows:

1. Have the vehicle on a level floor with the

transmission at operating temperature.

2. Move the selector lever through all positions and

then select P.

3. Allow the engine to idle for about two minutes.

4. With the engine idling, remove the dipstick and

wipe it with a non-fluffy rag or clean paper.

5. Insert the dipstick, then withdraw it immediately

and check the fluid level.

If the fluid level is low, add the correct type of fluid

to bring the level up to the full mark, but do not

overfill. If frequent topping up is necessary, then a leak

is indicated. This must be located and rectified

immediately, as a low fluid level will cause erratic

operation and damage to the transmission.

Some transmissions do not have a dipstick. In

these cases a fill plug will need to be removed from

the side of the transmission to allow the fluid level to

be checked and topped up if necessary.

481-506_May 2chap 24

13/9/06

4:14 PM

Page 483

chapter twenty-four automatic transmission service

■ When checking the dipstick, both the level and the

condition of the fluid should be checked. See the

later section ‘Dipstick information’.

Fluid change

Some transmissions have a drain plug that enables the

fluid to be drained without removing the oil pan

(Figure 24.2(a)). Other transmissions have no drain

plug and the oil pan has to be removed to change the

fluid. This allows additional servicing, such as filter

cleaning or replacement to be carried out.

When the transmission is drained, fluid will also

drain from the torque converter. However, the transmission will not drain completely because some fluid

will always remain in the lower part of the converter.

When removing an oil pan that has not been

drained, do not remove all the bolts – leave a bolt in

each corner. Loosen the front bolts but unscrew the

483

rear bolts a number of turns. The back of the oil pan

can be lowered onto the bolts so that most of the fluid

can be drained before it is completely removed.

The oil pan will probably be stuck to the transmission case and may have to be hit with a rubber

hammer to break the joint. Hit the edges or corners so

that the oil pan is not damaged.

After the oil pan is removed and before it is

cleaned, it should be examined for deposits (Figure

24.3). The colour of the fluid and the amount and types

of deposits in the oil pan and filter will indicate the

condition of the transmission, particularly the condition of the bands and clutches.

figure 24.3

Checking the deposits after removing the oil

pan HOLDEN LTD

Most oil pans are pressed sheet steel and can distort

as a result of uneven or excessive tightening. If this has

happened the oil pan sealing surface should be

straightened before refitting. Oil leaks can result if a

distorted oil pan is refitted.

Internal filter

A fluid filter is located underneath the valve-body

assembly (Figure 24.2(b)). This filters all the fluid

before it enters the oil pump.

Some filters are discarded and a new filter fitted as

part of the transmission service. Other filters have a

fine gauze screen which is cleaned, and the filter is

refitted.

■ During normal operation, the fluid in an automatic

transmission can reach temperatures in the vicinity

of 200°C. Care should be taken to avoid being

burnt by hot fluid when it is being drained.

figure 24.2

Oil pan and filter

(a) removing oil pan (b) filter bolted to the

valve-body assembly HYUNDAI

External fluid filter

Some transmissions are provided with an external fluid

filter. A filter of this type is fitted to the transaxle in

481-506_May 2chap 24

13/9/06

4:14 PM

Page 484

484 part four automatic transmissions and drive

Figure 24.4. This is similar to an engine oil filter.

When carrying out a service, the filter is removed and

discarded and a new filter is fitted.

control; heat transfer; lubrication of bearing surfaces;

epicyclic gear lubrication; and friction control. It has to

perform all these functions while operating at very low

temperatures, or at temperatures as high as 200°C.

oil filter

torque converter

dipstick

Additives in automatic transmission fluids

To enable an automatic transmission fluid to perform

the above functions, the following additives are used:

1. Anti-oxidants – to lengthen fluid life, permit high

temperature tolerance and prevent formation of

sludge and varnish.

2. Detergent/dispersants – to maintain contaminants

in suspension and keep hydraulic control

components and filter screens clean.

oil pan/cover

figure 24.4

Automatic transmission with an external

filter HYUNDAI

Refilling the transmission

Figure 24.5 shows the different levels of fluid in a

transmission when it is being refilled.

After draining the fluid, the normal method for

refilling is to add an initial quantity of fluid (approximately two-thirds the capacity) and then start the

engine to allow the converter to be filled. This reduces

the level in the transmission. The final fill is made with

the engine idling, to bring the fluid level up to the

‘full’ mark.

3. Corrosion inhibitors – to prevent oil degradation

products from corroding metal components.

4. Anti-wear additives – to prevent seizure of metal

components under load and provide maximum

protection against wear.

5. Seal swell additives – to provide control of swelling

of the rubber seals to prevent loss of fluid. Fluid

loss can lead to overheating and transmission

failure.

6. Viscosity index improvers – to maintain the correct

viscosity of the fluid over a wide temperature

range.

7. Pour point depressants – to permit fluid flow at

extremely low temperatures.

Automatic transmission fluids

8. Friction modifiers – to control the friction between

the clutch surfaces, enabling smooth gear changes.

Automatic transmission fluid has to perform many

functions such as: power transmission; hydraulic

9. Anti-foam additives – to ensure rapid collapse of

foam and rejection of any trapped air.

figure 24.5

Refilling a transmission

(a) initial quantity of fluid (overfull) (b) after starting (underfull) (c) after topping up and checking (correct level)

(d) after engine has been stopped for a period (overfull)

481-506_May 2chap 24

13/9/06

4:15 PM

Page 485

chapter twenty-four automatic transmission service

■ Fluid with the correct properties is critical for

ensuring smooth shifts and long clutch and band life.

Friction modified fluids

Figure 24.6 shows the difference between a friction

modified automatic transmission fluid and a nonfriction modified fluid.

The diagram shows that, when the speed difference

between the plates is close to zero (that is, when the

plates are grabbing or releasing), the frictional

coefficients of these two fluids are very different. The

non-friction modified oil grabs harshly and releases

quickly, producing a firm shift. The friction modified

oil grabs softly and releases softly, producing a soft

shift.

Manufacturers design the frictional material in their

transmissions to suit the recommended oil. Therefore,

if a type F fluid is used in a transmission which has

been designed for a Dexron type fluid this will produce

a bumpy or harsh shift.

If a Dexron type fluid is used in a transmission

which has been designed for a type F fluid, then a

different feel of shift could be expected. This would be

a particularly soft shift with the possibility of clutch

plate and band slippage under full power conditions.

Coefficient of friction

■ Some transmission specifications exclude the

addition of friction modifiers.

non-modified

Overheating of fluid

Operating conditions in automatic transmissions are

more severe than in manual transmissions mainly due

to the higher operating temperatures. For this reason,

automatic transmission fluids must be able to operate

over a very wide temperature range. This demands the

use of a stable viscosity index improver. Since the

fluid must also serve as a hydraulic control fluid,

relatively low viscosity base oils are used.

The frictional area of the transmission (mainly the

bands and clutches) generates approximately 50% of

the heat of the transmission fluid. The other major heat

source is the torque converter.

If excessive slip occurs in the bands and clutches,

the transmission fluid will be subjected to greatly

increased temperatures and these will degrade the fluid.

The diagram in Figure 24.7 illustrates the likely

relationship between fluid operating temperature and

the kilometres likely to be travelled before a transmission requires overhaul.

What the diagram does show is the advantage of

maintaining cool fluid in the transmission.

160

Thousands of kilometres

Clutch packs, convertor clutches and brake bands,

which are responsible for power transmission and also

for the feel of the gear shifts, require fluid with these

additives.

485

20

C

80∞

160∞

Transmission temperature

modified

figure 24.7

Graph shows the possible relationship

between the operating temperature and the

service life of an automatic transmission

almost

gripped

starting

to grip

Sliding speed between plates

figure 24.6

Comparison of friction-modified and nonfriction-modified fluids

Specific types of transmission fluids

There are five types of automatic transmission fluid in

general use:

481-506_May 2chap 24

13/9/06

4:15 PM

Page 486

486 part four automatic transmissions and drive

1. Type F. Used in Ford and Ford-type 3-speed

transmissions. It has no friction modifier and

therefore imparts a short, abrupt shift feel to the

transmission.

2. Dexron II. Used in Holden and Holden-type transmissions without electronic control. Gives a soft

shift feel characteristic to the transmission. Should

not be used for extended service interval units.

3. Dexron III. Supersedes all previous Holden Dexron

fluids. Soft shift feel. Suitable for non-serviceable

units and extended oil drain periods.

4. Ford 95 Fluid. Specially formulated for the BTR

4-speed unit supplied for Ford Falcon and Fairlane

models. Gives a very soft shift feel. Transmission

durability is enhanced with the use of this fluid.

between the cooler pipes and the transmission, or the

connections between the cooler pipes and the cooler.

Automatic transmission fluid has a distinctive

colour, and this enables automatic transmission leaks

to be distinguished from engine-oil leaks.

Figure 24.8 identifies the location of possible

engine oil and transmission fluid leaks in the torque

converter area of an automatic transmission. Some of

the fluid leaks might be cured by tightening the

housing bolts; other leaks can only be cured by

renewing an oil seal, an O-ring or a gasket. To do this,

the transmission might have to be removed from the

vehicle.

5. Mitsubishi M-SP Fluid. Specially formulated for

Mitsubishi, Hyundai and Proton transmissions

fitted with a damper clutch. Transmission, damper

clutch performance and durability could be affected

by not using this fluid.

■ Always consult the manufacturer’s recommendations when selecting an automatic transmission

fluid.

Fluid problems

Some of the possible problems associated with

automatic transmissions can be related to the fluid. For

this reason, the fluid should be one of the first things to

be checked.

Low fluid level

Low fluid level can produce many symptoms that can

be mistaken for more serious transmission problems.

Two of the most likely causes of low fluid level are

incorrect filling of the transmission during service, and

external leaks. However, before deciding that the

transmission is low on fluid, ensure that the fluid level

is being checked in the correct manner. If the manufacturer’s recommendation is not followed, a false

reading can easily be obtained.

■ If a fluid level problem is suspected be sure that the

check is being done correctly and the correct

dipstick is being used.

Fluid leaks

Oil seals and gaskets are possible sources of external

fluid leaks. Other possible places are the connections

figure 24.8

Possible sources of oil leaks in the converter

area – leaks could originate from the engine

or from the automatic transmission FORD

Transaxles, although of different design, could have

leaks from the area of the converter or from the oil

pan. Leaks are also possible from the joints between

the parts of the gear casing.

The drive-shaft oil seals, which seal between the

drive shafts and the final-drive housing, are also

possible places for oil leaks.

Internal leaks are more difficult to locate, but leaks

that cause problems usually result in a loss of pressure,

and this affects transmission operation. Pressure tests

can be carried out.

481-506_May 2chap 24

13/9/06

4:15 PM

Page 487

chapter twenty-four automatic transmission service

Dipstick information

While the dipstick is provided to measure the level of

the fluid in the transmission, it can also be used to

sample the fluid and provide a guide to its condition

(Figure 24.9).

487

problem probably exists within the transmission, the

likely one being that a clutch or band is slipping and

causing overheating.

Particles in the fluid

Fluid that is dark in colour, has a strong burnt odour

and is contaminated with small particles of foreign

matter, indicates problems.

The particles are the result of band or clutch slip

and wear. The discoloration is due to overheating and

degradation of the fluid as well as the particles that it

contains. A transmission with fluid in this condition

would probably require an overhaul.

Water contamination

Water in the fluid will cause it to emulsify and turn a

milky colour. Water contamination is not usual, but

could occur from some external source. It could also

occur if the cooler in the radiator was faulty.

The frictional material of the bands and clutch

plates is attached with water-based glue. If water

enters a transmission it can dissolve the glue and cause

the frictional material to become detached.

Extra cooling and filtering

figure 24.9

The fluid on the dipstick is checked for level,

colour and odour

The fluid on the dipstick can be checked as follows.

Fluid colour

If the fluid has its original distinctive colour, with no

discolouration, it can be considered to be in good

condition. Discolouration indicates that the fluid is in

poor condition. Badly discoloured fluid indicates that

there is probably a transmission problem as well.

Fluid odour

If the fluid has a noticeable burnt odour, it will also be

discoloured. This indicates that the fluid has

deteriorated due to overheating and should be changed.

If the transmission is operating properly, the fluid level

is correct, and the fluid is not badly discoloured, then a

change of fluid could be sufficient.

However, if the fluid is badly discoloured, a

Degradation of the transmission fluid will shorten the

life of a transmission. A vehicle that has severe or

heavy duty service (high loads, towing, heavy vehicle,

powerful engine) can have extra cooling and filtering

units fitted. These help to combat degradation and so

maintain the quality of the fluid.

Degradation of the fluid will occur by chemical

breakdown due to heat and by contamination from

metal particles and particles of friction materials.

■ The term degradation refers to a reduction in the

quality of the fluid.

Additional cooler

Automatic transmissions are fitted with a cooler (heat

exchanger) in the lower radiator tank. This transfers

heat from the transmission fluid to the relatively cooler

engine coolant.

A supplementary cooler can be fitted. This extra

cooler will help to extend the life of the transmission

fluid by maintaining it at optimum fluid temperature.

The additional cooler is like a small radiator

(Figure 24.10). It is fitted either in front of or behind

the engine coolant radiator where it can get maximum

air flow.

481-506_May 2chap 24

13/9/06

4:15 PM

Page 488

488 part four automatic transmissions and drive

The filter cannot be serviced and is discarded and

replaced with a new one when the transmission is

being serviced.

Transmission adjustments

1. an outer container – with fins to dissipate heat

Automatic transmissions and their controls are

provided with adjustments. These vary considerably

with different makes and models of vehicle.

The type and method of adjustment will depend on

whether the transmission has full hydraulic control,

or whether it has electronic control. It can also depend

on whether the engine has a carburettor or electronic

fuel injection (EFI).

Because of these differences, and the importance of

correct adjustment, it is essential that detailed information is obtained from the appropriate service manual

before attempting any adjustment on a vehicle.

The importance of checking the basic settings and

adjustments cannot be overstated – many service

complaints can be rectified by attending to the items

outlined below. A transmission simply cannot function

properly unless these are correct.

The following are the types of service adjustments

that are generally provided on automatic transmissions:

2. a powerful magnet – to remove fine steel particles

1. engine idle speed

3. a filter element – to remove foreign particles from

the fluid

2. selector cable, or linkage

4. a bypass valve – which opens if the paper element

becomes clogged.

4. throttle cable or vacuum control (for hydraulic

control)

inlet hose

cooler

outlet hose

figure 24.10

An automatic transmission cooler at the front

of the radiator HOLDEN LTD

Additional filter

Some transmissions are fitted with a replaceable fluid

filter, but a supplementary filter can be fitted in

conjunction with the cooler. The additional filter is

fitted into the cooler line, usually in the flexible line

and close to the transmission cooler for easy access. It

is an in-line filter so all the fluid passing to the cooler

first passes through the filter.

The filter construction is shown in Figure 24.11. It

consists of:

filter

element

magnet to attract

metal particles

3. starter isolator (neutral switch) or range switch

5. throttle-position sensor (for electronic control)

outlet

6. hydraulic pressure

7. brake bands.

Engine idle speed

steel core

polymer

casing

inlet

figure 24.11

by-pass valve

Magnetic in-line filter construction

BOSS

Idle speed is checked with a tachometer and adjusted

to the rpm specified for the vehicle (usually in the

vicinity of 800 rpm).

Adjustment is made with the selector lever in P,

and is finally checked for smooth idling in D. A slight

drop in engine rpm will be noticed when the selector is

moved to D. This is caused by the increased load on

the engine.

High idle speed will cause creep; that is, the vehicle

will move slowly as soon as a gear position is selected,

even with the engine idling. Creep is normal, but it will

be excessive if the idle speed is too high.

High idle speed could also cause a band or brake to

481-506_May 2chap 24

13/9/06

4:15 PM

Page 489

chapter twenty-four automatic transmission service

489

be applied harshly when the selector lever is moved to

a gear position. Low idle speed will cause the engine

to stall.

There are different methods of adjusting the idle on

carburettor and EFI engines, but the effects of

incorrect adjustment are the same.

■ For safety reasons, engine idle or any other engine

adjustments should only be carried out with the

selector lever in the N or P position with the park

brake applied.

Selector cable

The selector cable connects the driver’s selector lever

to the manual valve in the transmission, so that

whenever a gear position is selected, the manual valve

will be moved to that position. For the selector

adjustment to be correct, the selector lever indicator

should be in the N position with the manual valve also

in the N position.

The two ends of a selector cable are shown in

Figure 24.12. The selector lever and its end of the

cable are shown in Figure 24.12(a) and the transaxle

end of the cable and its lever arrangement are shown in

Figure 24.12(b). This is a push–pull cable which

enables the selector lever to move the lever on the

transaxle case in both directions.

A threaded adjustment is provided at the selector

lever. This is adjusted so that the selector positions at

the selector lever correspond with the selector

positions at the transaxle. In the design shown, a roller

and quadrant are used to locate the selector lever in the

various selector positions. Inside the transaxle, a detent

locates the manual valve in its correct positions. The

adjustment is made with the selector lever in N and the

manual valve also in N.

figure 24.12

The starter isolator or neutral switch

This is usually located on the transmission case (Figure

24.13). This is a safety switch, arranged to prevent the

engine from starting in any gear position except N or

P. Incorrect operation of the switch would allow the

engine to be started with the transmission in gear,

causing the vehicle to move out of the control of the

driver.

The isolator switch forms part of the starter

solenoid circuit. It is operated by the gear-selector

mechanism to provide an open circuit in all positions

except N or P. This prevents the starter from operating

in any other position.

Selector lever

(a) lever and selector end of cable (b) transaxle end of cable FORD

■ The isolator switch is also called the neutral switch,

inhibitor switch and sometimes the range selector

switch.

Checking the isolator switch operation

To check that the switch isolates the starter, try to start

the engine with the selector lever in all positions. The

starter should operate in N and P only. Check this while

moving the selector lever backwards and forwards

(within the free play) from N and also from P.

481-506_May 2chap 24

13/9/06

4:15 PM

Page 490

490 part four automatic transmissions and drive

electrical

connector

range switch

mounting bolts

manual control

lever

(a)

figure 24.13

Starter isolator and position switch, rotary

type MITSUBISHI

As a safety precaution, firmly apply the parking

brake and foot brake during the check because the

vehicle could move if the switch is incorrectly

adjusted.

To check the switch itself, the harness connector

will have to be disconnected at the switch and an

ohmmeter used to check between the terminals at the

switch connector. The ohmmeter is connected between

the terminals, and the switch moved to each of the gear

positions.

adjusting nut

manual

control

lever

range switch

(b)

figure 24.14

Manual control lever and range switch

(a) switch assembly (b) cable adjustment

HYUNDAI

Checking the range switch operation

With electronic control, the isolator switch is also a

position switch. It sends signals to the ECU to tell it

which position has been selected. In some vehicles, the

isolator switch is called the range switch. An example

is shown in Figure 24.14.

Some vehicles have the selector positions (or range

positions) shown as indicators on the instrument

cluster (Figure 24.15). With this arrangement, the

range selector switch is used to illuminate the position

that is selected.

When checking the operation of the switch, the

panel indicators should also be checked.

(a) Range indicators

Throttle cable

There are two cables in the accelerator and throttle

cable arrangement. One is the accelerator cable

between the accelerator pedal and the throttle valve in

the throttle body of the engine’s air intake system. The

other is the throttle-valve cable, which connects the

throttle valve to the hydraulic throttle valve (TV valve)

in the transmission.

To avoid confusing the two valves, the throttle

valve in the air intake will be referred to simply as the

malfunction

indicator

indicators

(b) Instrument cluster

figure 24.15

Automatic transmission range indicators on

an instrument cluster HYUNDAI

throttle valve, while the hydraulic valve in the transmission will be referred to as the TV valve.

481-506_May 2chap 24

13/9/06

4:15 PM

Page 491

chapter twenty-four automatic transmission service

An arrangement with two cables is shown schematically in Figure 24.16. When the accelerator pedal is

depressed, the throttle valve is opened by the accelerator cable movement. The transmission downshift

valve and the TV valve are moved by the action of the

throttle cable.

throttle

body

accelerator

accelerator

cable

491

accelerator cable

throttle

body

outer

cable

(a)

throttle valve

(TV valve)

boot

throttle

cable

A

adjustment

plunger

lever

figure 24.16

Throttle cable arrangement

ferrule

HOLDEN LTD

(b)

Throttle linkage adjustment is correct when the

accelerator pedal height, the throttle valve opening,

and the position of the TV valve in the transmission

are in correct relationship.

In general terms, the relationship of these three is as

follows:

1. The pedal should be of sufficient height above the

floor to allow full movement of the linkage.

2. The throttle valve should be closed (at idle

position).

3. The TV valve in the transmission should be at or

near its stop.

The manufacturer’s method of adjustment should

always be referred to, as any errors will affect both the

fluid pressure and the road speeds at which gear

changes occur.

■ Incorrect adjustment, because of low line pressure,

could cause the transmission to slip, resulting in

erratic changes and damage to bands or clutches.

Cable adjustment

The throttle valve ends of both an accelerator cable

and a throttle cable are shown on Figure 24.17. Both

the inner cables operate around quadrants. With this

arrangement, the accelerator inner cable shortens and

the TV valve inner cable lengthens when the accelerator pedal is pressed.

figure 24.17

Throttle cable assembly and adjustment

TOYOTA

To check this particular arrangement, the accelerator cable is checked first: depress the accelerator

pedal and check that the throttle valve is fully open. If

necessary, adjust the length of the cable with the

adjusting nuts until the throttle valve opens fully.

With the accelerator pedal fully depressed, check

that the throttle inner cable has moved out far enough

to expose a stop which is crimped to the inner cable.

The stop should be about 1 mm beyond the end of the

boot on the cable. If necessary, adjust the nuts on

the outer cable to obtain this dimension (A in Figure

24.17(b)).

As with all transmissions with hydraulic control,

the throttle cable adjustment affects throttle pressure in

the transmission and throttle pressure operates on the

shift valves. If the outer cable is lengthened (the inner

cable effectively shortened), then throttle pressure in

the transmission will increase and delay upshifts. If the

outer cable is shortened, this will have the opposite

effect and upshifts will occur earlier.

In the transmission, throttle pressure operates on

the regulator valves as well as on the shift valves. This

means that both line pressure and converter pressure

can be affected by throttle cable adjustment. If line

pressure is too high, the shifts will be harsh as well as

481-506_May 2chap 24

13/9/06

4:15 PM

Page 492

492 part four automatic transmissions and drive

late. If the pressure is too low, upshifts will be early

and clutches or bands could slip.

Vacuum control

A vacuum control unit is shown in Figure 24.18. This

performs a similar function to the throttle linkage.

figure 24.18

Vacuum-operated throttle valve

1 line pressure, 2 throttle pressure, 3 throttle

pressure, 4 exhaust

The unit, which is mounted on the transmission case,

consists of a diaphragm in a sealed container connected

by a pipe to the engine manifold. The diaphragm is

under the influence of engine manifold vacuum and

therefore is sensitive to variations in engine load.

A pushrod from the diaphragm extends into the

transmission and operates the throttle valve (TV

valve). Changes in throttle butterfly opening and

engine load will therefore affect throttle pressure,

which will determine when gearshifts occur. (Line

pressure will also be affected.)

Adjustment, if necessary, can be made either by

changing the length of the pushrod between the

diaphragm and the throttle valve or by turning a small

screw located inside the vacuum connection.

Kickdown

Where a throttle cable is used, the downshift valve is

operated by the cable and no adjustment is required.

Where vacuum control is used, forced downshifts

are obtained by means of a kickdown switch operated

by the accelerator linkage, and a solenoid which

controls a downshift valve in the transmission

(Figure 24.19).

When the accelerator pedal is depressed to the

floor, the switch contacts are closed, the solenoid is

energised and downshift pressure is provided to the

shift valves to force a downshift. An adjustment is

provided on the switch or the linkage, and this can be

altered if the switch does not operate.

figure 24.19

Kickdown (downshift) switch and solenoid

MAZDA

Throttle-position sensor

The throttle-position sensor, used with electronic

control, is attached to the throttle body. The sensor can

usually be adjusted, within limits, by loosening the

screws and altering its position.

There are two basic types of sensors: one is a

rheostat and the other is a switch. The rheostat provides a voltage signal that varies with throttle opening.

It is basically a variable resistance, so can be checked

with an ohmmeter (Figure 24.20). Its resistance should

vary between closed-throttle and full-throttle positions.

The switch-type sensor provides signals in a

number of steps. It is actually a switch with a number

of contacts. For checking purposes, it can be treated in

the same way as any other switch.

Brake band adjustments

These are carried out to compensate for wear of the

band lining. A loosely adjusted band could slip,

resulting in overheating and excessive wear. A tightly

adjusted band will cause binding, again resulting in

overheating and wear. Correct adjustment provides a

small clearance between the brake band and the drum.

481-506_May 2chap 24

13/9/06

4:15 PM

Page 493

chapter twenty-four automatic transmission service

electrical

connector

ohmmeter

493

inside the transmission. The oil pan has been removed

and a small tension wrench is being used on the screw

adjuster. In most transmissions the band is adjusted by

tightening the adjusting screw to a specified torque and

then backing the screw off a specified number of turns.

Gauge blocks are sometimes used.

External adjustment

The adjustment shown in Figure 24.22 is an external

adjustment, which is accessible after removing the

outside cover from the servo.

plenum

chamber

figure 24.20

throttle

body

Checking the throttle-position sensor

HYUNDAI

This enables the band to be applied smoothly and

firmly, with minimum wear occurring.

Some transmissions have two band adjustments

while others have only one. Some automatic transmissions have disc brakes instead of bands, and these

have no adjustments.

■ The band adjuster may be internal or external.

Internal adjustments can only be carried out after

the oil pan has been removed.

Internal adjustment

Figure 24.21 shows a band adjustment being carried

out on a transmission; in this case, the adjustment is

figure 24.22

Servo and band with an external adjustment

The following is an example of how a band is

adjusted:

1. Loosen the locknut.

2. Holding the servo piston to prevent it from turning,

tighten the adjusting screw to 10 Nm and then back

it off. Repeat this twice. This is done to seat the

band snugly on the drum and so prevent a false

reading when adjusting.

3. Tighten the adjusting screw to 5 Nm and then back

it off 31/2 turns.

4. Tighten the locknut to 15 to 20 Nm.

Fault diagnosis and checks

An understanding of the construction and operation of

the particular type of transmission or transaxle is

necessary to enable faults to be diagnosed and checks

to be made. While the general operating principles of

most transmissions are similar, the details vary greatly.

figure 24.21

Servo and band with an internal adjustment

MITSUBISHI

■ Vehicle manufacturers provide diagnosis guides,

and these should be referred to whenever a fault is

suspected.

481-506_May 2chap 24

13/9/06

4:15 PM

Page 494

494 part four automatic transmissions and drive

Basic checks

Where an automatic transmission has an operational

problem, there are a number of preliminary checks that

can be carried out. These will provide information and

possibly correct minor problems.

1. Fluid level. Check the fluid level, top up if

necessary and check for external leaks.

2. Fluid condition. Check the fluid for deterioration

and contamination.

readings are taken for different operating conditions

(Figure 24.23).

As an example, specifications for line pressure

could be: 350 kPa at idle and 700 kPa at 1000 rpm.

These tests would be taken with the selector in

D position. The pressure in reverse could be up to

1000 kPa.

■ Pressure readings can also be taken during road

tests.

3. Engine idle. Check and adjust the engine idle speed

to specifications.

4. Throttle cable or linkage. Check for free operation

and ensure that there is no lost motion. Adjust to

specifications. Check to ensure full throttle is

available.

5. Selector linkage. Check operation of linkage and

starter neutral switch.

6. Electronic controls. Check ECU self-diagnosis for

faults.

7. Electrical connections. Check all electrical connections associated with the transmission sensors

for looseness or corrosion.

figure 24.23

8. Battery terminals. Check both battery terminals for

looseness or corrosion.

It is important that these checks are carried out,

because the checks, and related adjustments, will

correct many of the less serious operating problems.

■ The checks should be made and the vehicle road

tested before any internal repairs are considered.

In addition to the above, band adjustments can be

carried out. Where this entails removing the oil pan, as

much diagnosis as possible should be carried out

before this is done. This will enable the transmission to

remain operational until a decision on the problem is

reached. Dismantling, if considered necessary, can

then be carried out.

Where further diagnosis is needed, a pressure test

or a stall test can be carried out.

For a transmission with electronic control, test

instruments would be used to extract self-diagnosis

information from the ECU (see later sections).

Pressure check

A pressure check can be carried out as an aid to

diagnosing hydraulic problems. For this test, a pressure

gauge is connected to the transmission, and pressure

Oil pressure gauge connected to check the

line pressure of a transaxle

Stall test

A stall test checks the engine, the torque converter and

the transmission by measuring the maximum rpm that

the engine can produce with the turbine held in a

stalled condition.

To make the test, the vehicle is held stationary with

brakes and wheel chocks, the selector lever is placed in

D, and the throttle is opened fully for a very short

period. The test conditions are shown in Figure 24.24.

A tachometer connected to the engine registers the

engine rpm, and this is used to interpret engine and

transmission condition. As well as this, a pressure

gauge can be connected to the transmission to check

the system fluid pressure.

The tachometer reading is specified by the manufacturer, for example 1450 rpm to 1750 rpm, although

these figures will vary for different engines. If the

tachometer reading comes within these figures, then

the transmission and converter are satisfactory.

A low rpm reading can indicate that the engine is

suffering from loss of power, a clogged exhaust, or it

can be caused by a slipping stator in the converter

which is placing a greater than normal load on the

engine.

481-506_May 2chap 24

13/9/06

4:15 PM

Page 495

chapter twenty-four automatic transmission service

495

figure 24.24

Stall testing an automatic transmission

1 chock the wheels, 2 apply parking brake, 3 connect tachometer, 4 select D, 5 apply brakes and open throttle –

stall test only if allowed by manufacturer

A high rpm reading can be caused by slipping

bands and clutches or mechanical damage in the

converter. In either case, further investigation is

necessary to isolate the problem.

Information should be obtained from the appropriate workshop manual before a stall test is attempted.

It should be realised that stall testing generates high

fluid temperatures and places severe loadings on all

parts of the transmission and drive line as well as on

the engine.

Some manufacturers recommend against stall

testing and others allow partial stall testing only.

A stall test should be performed only during

diagnosis, and then only when permitted for the

particular transmission.

Checks are made at different throttle openings and at

different speeds, with the selector lever in different

positions.

Road testing

Smooth engagement

When road testing a vehicle with an automatic

transmission, checks are made of:

The bands should be applied smoothly when the

selector lever is moved through the various positions.

Reverse may be a little harsher, as higher fluid

pressures are often used.

1. selector lever operation (including the isolator switch)

2. the shift pattern (road shift speeds)

3. the shift quality (engine overspeeding between

shifts, or slippage)

4. noise in the transmission.

■ Before commencing a road test, check correct

operating temperature, engine idle and fluid level.

General test procedures

The general procedure for a road test is illustrated in

Figure 24.25.

During a road test, observe the following points.

Starter isolator switch

The starter should operate only in N or P positions.

This is an important safety feature that must be

checked.

Upshifts

Upshifts should be checked on a level road to

determine if they occur at the correct road speeds.

481-506_May 2chap 24

13/9/06

4:15 PM

Page 496

496 part four automatic transmissions and drive

figure 24.25

Checks that can be made during a road test of an automatic transmission or transaxle

Checks should be made at minimum throttle, full

throttle and kickdown positions. The shifts should

occur at the speeds specified by the vehicle

manufacturer. (Refer to Table 24.1 for examples of

shift speeds. The table is for a transmission with a

hydraulic governor.)

481-506_May 2chap 24

13/9/06

4:15 PM

Page 497

chapter twenty-four automatic transmission service

Downshifts

Downshifts occur at lower speeds than upshifts. These

can be checked at closed throttle, and, where suitable

conditions are available, at full or part throttle on hills

to check downshifts under load. Forced downshifts

(kickdown) can also be checked.

Overdrive

For transmissions with overdrive or similar switches,

gearshifts can be checked with the overdrive switch

both on and off. With the overdrive switch off, there

should be no upshifts from third to fourth gear. When

the switch is turned on at higher speeds, the

transmission should shift from third to fourth.

Power and economy modes

For transmissions with electronic control that have

power and economy modes of operation, the shift

speeds can be checked in both modes. There may not

seem to be much variation in road speeds, but the

power indicator lamp should light with the power

mode selected.

Shift quality

The shifts should be checked for both harshness and

slip. This should be done under light-load and also

heavy-load conditions. Checks can be made both on a

level road and on hills. Any tendency for the engine to

overspeed during shifts can also be observed.

Low and second positions

Select 1, and check that upshifts do not occur. Do not

overspeed in this gear. Position 2 can be selected with

the vehicle stopped and then changes observed from 1

to 2 as vehicle speed is increased.

Parking pawl

With the vehicle stopped on a hill, select P and release

the brakes to check that the parking pawl will hold.

The brakes should be reapplied before moving the

selector lever from the park position.

Reverse

With the vehicle stopped, select R and check for slip

and noise. Some additional gear noise is not unusual in

reverse.

Shift patterns

The road speed at which the various gearshifts occur is

determined by the governor (hydraulic control), the

497

road-speed sensor (electronic control) and the amount

that the accelerator is depressed by the driver.

Road-speed checks are made at defined throttle

openings. In some transmissions, three positions are

checked: light throttle, full throttle and kickdown.

Other transmissions have shift patterns specified for

different throttle positions, such as quarter, half and

full throttle. Percentage of throttle opening is also

used, for example shift speeds at 5% and 80%. The

shift speeds should be within the specifications for the

particular transmission.

With hydraulic control, the shift speeds can be

corrected by adjusting the throttle linkage or by

altering the length of the pushrod where a vacuum

control is fitted.

With electronic control, the shift patterns are

embedded in the memory of the ECU. With an

electronically controlled transmission a shift-speed

problem is therefore more likely to be related to the

throttle-position sensor or road-speed sensor rather

than to hydraulics.

On most transmissions the driver can alter the shift

pattern by the use of a power/economy switch. When

the transmission is in economy mode the upshifts will

generally occur earlier than they would when in power

mode.

Adaptive Learning Strategy

Some transmissions employ an adaptive learning

strategy. This has the capability of automatically

modifying the programmed shift pattern to suit the

driving habits of each individual driver. This has to be

considered when road testing a transmission with this

feature.

An ECU with this program receives information

from sensors which enables it to monitor parameters

such as steering wheel turn, vehicle speed, throttle

operation, brake operation, gearshift mode, engine rpm

etc. The ECU recognises the combination of these

parameters as a distinctive pattern for each driver and

adjusts the shift pattern to suit that individual.

As a simple example, a driver might use more throttle

when taking off in an attempt to accelerate more quickly.

The ECU recognises this aspect and will delay the

upshifts for that driver resulting in a quicker get-away.

As another example, another driver might drive

cautiously when descending hills or approaching

corners. The ECU recognises this aspect and will

change the shift pattern to earlier downshifts which

slow the vehicle due to increased engine braking.

481-506_May 2chap 24

13/9/06

4:15 PM

Page 498

498 part four automatic transmissions and drive

■ See the previous chapter for more information on

electronic control of shift patterns.

Table of shift speeds

Table 24.1 is one example of the shift pattern for a

transmission, but they can be shown in a variety of

ways, including a graph. The shift speeds listed for a

transmission should be treated as approximate speeds,

not as exact speeds. ‘Light throttle’ means just

sufficient accelerator movement to cause the vehicle to

increase speed. ‘Full throttle’ occurs when the

accelerator is pressed almost to the floor, and ‘kickdown’ is when the accelerator is fully depressed. In

some vehicles, there is a resistance to movement

between full throttle and kickdown. In other vehicles,

kickdown operates the kickdown switch and solenoid.

table 24.1

Table of shift patterns

THROTTLE

Light

Full

Kickdown

Closed

Full

Kickdown

and electronic controls must all be considered. Table

24.2 shows these and indicates some of the things that

might cause problems in the different locations. As an

example, do not immediately blame the transmission

for a problem that could be caused by the engine not

performing properly.

■ It is also possible that a faulty torque converter

could cause what appears to be poor engine

performance.

table 24.2

General location of automatic transmission

problems

LOCATION

POSSIBLE PROBLEMS

Engine

Lack of power

Engine needs tune-up

Idle speed incorrect

Torque converter

Low pressure

Converter lock-up clutch fault

Stator OWC stuck or slipping

Mechanical/power

train

Cables or linkage

Band adjustment

Band worn

Clutch faulty

Transmission OWC slipping

Gearing damaged or noisy

Hydraulic system

Cable adjustment

Low pressure

Valves sticking

Fluid leaks

Leaking solenoid valve

Governor or valve faulty

Clutch piston

Servo

Electronics/electrics

Isolator switch or position

Sensor switch faulty or needs

adjusting

Electrical cable fault

Connector making poor contact

Road-speed sensor fault

Throttle sensor adjustment or

fault

Other sensor fault

Solenoid not operating

ECU fault

Loose or dirty battery terminals

Low alternator output

SHIFT SPEEDS (KM/H)

UPSHIFT

1–2

UPSHIFT

2–3

UPSHIFT

3–4

12–20

40–45

45–55

21–30

60–70

70–90

35–40

80–90

DOWNSHIFT

2–1

DOWNSHIFT

3–2

DOWNSHIFT

4–3

5

10

35

20

20–25

60–70

25–30

30–35

■ During road-speed checks, speed should be kept

within the legal speed limit for the area in which

the vehicle is being driven. Road testing is

distracting to the driver so extra care is required.

Diagnosing problems

Workshop manuals provide diagnosis guides and

charts which should be referred to whenever a problem

arises. These guides are often very extensive, with

some providing step-by-step procedures.

In the event of a problem, the basic checks should

be carried out, as previously discussed, so that the

simpler things are checked and eliminated first. If the

problem has still not been cured, the more difficult

things can be investigated.

When diagnosing an automatic transmission

problem, the engine, power train, hydraulic controls

A general diagnosis guide is shown in Table 24.3.

This is not designed for any particular transmission.

However, it can be used to identify the types of

problems that can occur with automatic transmissions.

481-506_May 2chap 24

13/9/06

4:15 PM

Page 499

chapter twenty-four automatic transmission service

table 24.3

Diagnosis guide for an automatic transmission

PROBLEM

POSSIBLE CAUSES

No starter operation in N or P

Starter operates in other

than N or P

No engagement in D

No engagement in any

selector position

Delayed engagement

Slip or noise on take-off in D

9, 31, 41

9, 31

20, 9, 21, 24

9, 21, 16, 32, 8, 20

24, 21, 11, 31, 33, 42, 43

20, 11, 25, 16, 15, 17,

28, 36, 37

Slip or noise on take-off in

20, 11, 21, 25, 16, 15,

reverse

17, 28, 36, 37

Harsh engagement all positions 1, 11, 24, 25, 23, 36, 37

Poor acceleration in first

2, 4, 14, 15, 16, 17

Poor performance and

2, 3, 30

overheating in third

No 1–2 shift

6, 17, 29, 34, 36, 42, 43

Slip during 1–2 shift

20, 11, 25, 16, 17, 15,

sometimes

27, 21, 36, 42, 43

Harsh 1–2 shift

11, 24, 25, 23, 36, 37,

32, 42

No 2–3 shift sometimes

9, 15, 27, 29, 34, 32, 36,

42, 43

Slip during 2–3 shift

20, 11, 24, 21, 36, 42, 43

Harsh 2–3 shift

11, 24, 23, 36, 37, 42, 43

Soft shifts

21, 16, 17, 11, 36, 37, 40

No 3–4 shift

39, 32, 15, 16, 17, 29,

32, 36, 42, 43

Shift speeds incorrect

11, 24, 28, 29, 33, 40,

42, 43

No engine braking in 1 position 16, 17, 27

Whine in N with engine running 13

Grating noise from transmission 12, 18, 19

Knocking noise from converter 4, 5, 8

Park will not hold

9, 12

Transmission overheating

30, 20, 3

No converter clutch lock-up

5, 6, 8, 24

Transmission binds

27, 16, 22, 26

Engine stalls

1, 2

Engine flare between shifts

22, 16, 17, 20, 42, 43

Vehicle has excessive creep

1

No forced downshift

11, 38

Diagnosing electronic control problems

Transmissions with electronic control have a selfdiagnosis program in the ECU which can diagnose

faults as they occur during operation.

If a sensor or component of the electronic control

system is not functioning properly, then it will send

abnormal signals to the ECU. When the ECU receives

an incorrect signal, its self-diagnosis program

recognises that the signal is not normal and records a

fault in that part of the system. In most cases, the

information will remain in the memory of the ECU

until the battery is disconnected.

table 24.3

499

Diagnosis guide for an automatic transmission

(continued)

KEY TO POSSIBLE CAUSES

Engine

1. Idle speed

2. Lack of power

Torque converter

3. Stator OWC stuck

4. Stator OWC not locking

5. Converter clutch

6. Pressure low

7. Converter solenoid

inoperative

8. Converter damage

Mechanical/power train

9. Selector cable or

linkage adjustment

10. Inhibitor switch

adjustment, or fault

11. Throttle cable or

linkage adjustment

12. Parking pawl or

mechanism damaged

13. Oil pump worn or

damaged

14. Transmission OWC not

locking

15. Clutch plates worn

16. Band adjustment

17. Brake bands or plates

worn

18. Gearing worn or

damaged

19. Worn bearings or

thrusts

Hydraulic system/controls

20. Fluid level low

21. Low line pressure

22. Internal fluid leaks

23. High line pressure

24. Valves sticking

25. Vacuum control fault or

leak

26. Clutch piston sticking

27. Servo piston

28. Governor valve sticking

29. Shift valves sticking

30. Cooler inefficient or

line blocked

Electronics/electrics

31. Isolator/selectorposition switch

adjustment, or fault

32. Wiring or connectors

33. Throttle-position

sensor adjustment,

or fault

34. Speed-sensor fault

35. Oil-temperature

sensor

36. Shift solenoid

37. Pressure-regulator

solenoid

38. Kickdown switch or

solenoid

39. OD switch fault

40. ECU fault

41. Anti-theft system

armed

42. Loose or corroded

battery terminal

43. Low alternator

output

The ECU provides fault information in the form of

codes. Depending on the system, these are obtained

from it by means of a voltmeter, an LED test lamp, or

specialised test equipment such as a scan tool. In some

cases, the transmission power-mode lamp on the

instrument panel can be used for diagnosis.

To obtain the codes, the vehicle must have been

operated so that the fault is recorded. The test equipment is then connected into the system, usually by

means of special connecting cables into a diagnosis

connector provided for the purpose. The ignition

switch is turned on, but the engine is not running.

481-506_May 2chap 24

13/9/06

4:15 PM

Page 500

500 part four automatic transmissions and drive

Diagnosis codes

The codes are given numbers, and these are interpreted

by the operator from the way in which the light glows,

the way in which the pointer of a voltmeter flicks, or

from the test instrument. Specialised testers can show

the code, or a pulse pattern trace, or other information

on a liquid-crystal display panel.

LED codes

Figure 24.26 shows how an LED test lamp can signal

code numbers from the ECU. Each flash of light from

the LED represents a single digit, so code No. 1 is

shown by a single flash of light which lasts for one-third

of a second. This is the normal condition, and code No.

1 shows that there are no faults recorded. The light will

flash the code again after three seconds, and will

continue to do so as long as the test lamp is connected.

figure 24.26

No. 3, faults

table 24.4

Diagnosis codes

CODE NO.

NUMBER OF

FLASHES

MEANING

1

2

3

4

5

6

7

1

2

3

4

5

6

7

Normal operation, no faults

Vehicle-speed sensor No. 1

Solenoid No. 1, or wiring

Solenoid No. 2, or wiring

Throttle-position sensor

Shift-position switch

Vehicle-speed sensor No. 2

Scan tool

Figure 24.27 shows a special tester or scan tool which

is used to obtain diagnosis codes and other

information. This is connected to the data link

connector (DLC). The same tester is used for

diagnosing problems in the engine’s electronic fuelinjection system and other electronic systems of the

vehicle.

Diagnosis faults shown by an LED test lamp

(a) code No. 1, normal (b) codes No. 2 and

DLC

DAIHATSU

scan tool

For code No. 2, there will be two flashes close

together. These are one second apart and are followed

by a pause of three seconds before the code is

repeated. If there is more than one fault in the memory,

a different code will follow. The codes will appear in a

sequence starting with the smallest number and

finishing with the largest.

Table 24.4 is an example of the information

provided by the code. It shows the diagnosis code

number, the number of flashes of the LED, and the part

of the system that has the fault. Having read the code

number, the table is then used to interpret the code.

This table, with its seven codes, is a relatively simple

one. Some transmissions have many more diagnosis

codes.

figure 24.27

Scan tool tester connected to a data link

connector (DLC) to check for automatic

transmission problems HYUNDAI

Indicator lamp

Another method of displaying codes is shown in

Figure 24.28. In this transmission, the power indicator

lamp is used to flash out the code number.

Components

While the self-diagnosis tests identify the section of

the system that has a fault, further testing is needed to

isolate the fault to the sensor, connector, wiring or

other particular part of the system. A voltmeter is used

to check the voltage at particular connectors, and an

481-506_May 2chap 24

13/9/06

4:15 PM

Page 501

chapter twenty-four automatic transmission service

501

Transmission overhaul

A transmission will have to be dismantled and overhauled if a major problem exists. This requires

specialised knowledge, special tools and the appropriate workshop manual to carry out satisfactory

repairs.

Transmission overhaul is beyond the scope of this

chapter, but the following illustrations show the construction of some transmissions. These enable the

internal parts to be identified.

■ When a new or overhauled transmission is fitted,

relearn procedures as specified by the manufacturer

should be followed. See the information on adaptive

learning strategy earlier in the chapter.

Transmission construction

figure 24.28

Fault code from the power indicator light

(a) first long flash and second short flash

indicates speed-sensor circuit fault (b) simplified speedsensor circuit with a sensor in the speedometer head

ohmmeter is used to check the resistance of components or other parts of the circuit.

■ Only recommended testing equipment should be

used. Other test equipment that draws too high a

current can damage the ECU. The allowable

current is only a few milliamps. A normal test lamp

with an incandescent bulb should not be used with

electronic components.

Fail-safe function

If a fault occurs in a part of the electronic control

system which will affect the driveability of the vehicle,

then the fail-safe function comes into operation. The

ECU will place the faulty part of the system in the

default mode. This means that instead of a variable

signal from the sensor, a fixed signal will be used. The

transmission will continue to operate, but not as

efficiently as it normally would. In the workshop, the

self-diagnosis function can be used to identify the

problem.

■ The fail-safe function is sometimes referred to as

the limp-home mode.

There are many variations in automatic transmission

design and the illustrations that follow are examples.

Figure 24.29 is a sectional view of an electronically

controlled, four-speed automatic transmission for a

rear-wheel-drive vehicle. This transmission has two

epicyclic gear sets which, when directed by the ECU

(in this case the power control module (PCM)), provide four forward gears and a reverse gear. The

transmission has five clutch packs, one brake band,

one sprag type one-way clutch and one roller type oneway clutch. The transmission has a lock-up torque

converter.

Another example is shown in Figure 24.30. This

unit is basically a three-speed transmission with an

overdrive unit for fourth gear.

Figure 24.31 is a sectional view of an automatic

transaxle. This is a three-speed transaxle with two

separate gear sets with a common sun gear. As well as

the planetary gearing, the idler gear, final-drive gear

and differential assembly can be seen. This has fewer

parts than a four-speed transaxle, so it is easier to

identify the parts in this illustration.

A four-speed transaxle is shown in Figure 24.32.

This has compound planetary gearing, four multiplate

clutches, two brakes and two one-way clutches to

provide the four forward gears and reverse. It has a

converter clutch and electronic control.

Transmission and transaxle parts

To gain familiarity with the parts and construction of

automatic transmissions, the illustrations should be

used to identify the main parts. As a guide, look for the

481-506_May 2chap 24

13/9/06

4:15 PM

Page 502

502 part four automatic transmissions and drive

5

3

1

2

21

23

22

7

4

6

19

20

9

8

17

12

14

16

18

11

10

13

15

figure 24.29

A four-speed automatic transmission with electronic control

1 case, 2 reverse input clutch, 3 input clutch housing, 4 overrun clutch, 5 forward clutch, 6 forward clutch sprag

assembly, 7 3–4 clutch, 8 input planetary gear set, 9 low and reverse clutch, 10 low roller clutch, 11 reaction planetary gear set,

12 output shaft, 13 speed sensor, 14 parking pawl, 15 park lock actuator, 16 control valve assembly, 17 manual shaft, 18 inside

detent lever, 19 2–4 band, 20 pump assembly, 21 stator roller clutch, 22 torque converter, 23 turbine shaft HOLDEN LTD

following: torque converter parts, lock-up clutch, input

shaft, output shaft, gearing, clutches, brakes and bands,

one-way clutches, final drive and gears, parking pawl

and gear, oil pump, valve-body assembly.

Review questions

1.

How is the fluid level checked in an automatic

transmission?

2.

What precautions are needed when draining the

fluid from an automatic transmission?

3.

What information can be gained from the fluid

on the dipstick?

4.

Why must the correct type of fluid be used?

5.

What are the different types of fluids?

6.

Name some of the properties of automatic

transmission fluid, and indicate why the fluid

has these properties.

7.

What effect does excess transmission fluid

temperature have on the transmission?

8.

What is the effect of incorrect engine idle speed

on a vehicle with automatic transmission?

Technical terms

Degrade, degradation, deposits, topping up, automatic transmission fluid, ATF, Dexron, viscosity

index, oxidation, foaming, extreme-pressure

additives, chemical action, detergent, fluid odour,

discoloration, contamination, isolator switch,

selector cable, throttle cable, creep, vacuum control,

kickdown, line pressure, electronic controls,

throttle-position sensor, converter pressure, rheostat,

power mode, diagnosis codes, stall test, road test,

shift pattern, shift speeds, shift quality, selfdiagnosis, fail-safe, default mode, adaptive learning

strategy.

481-506_May 2chap 24

13/9/06

4:15 PM

Page 503

chapter twenty-four automatic transmission service

503

figure 24.30

Automatic transmission with overdrive

1 converter housing, 2 torque converter, 3 oil pump, 4 overdrive planetary gears, 5 direct clutch, 6 drum support,

7 intermediate shaft, 8 second brake band, 9 front clutch, 10 rear clutch, 11 front planetary gears, 12 rear planetary gears,

13 one-way clutch, 14 disc brake, 15 transmission case, 16 governor, 17 extension housing, 18 output shaft, 19 oil distributor,

20 valve-body assembly, 21 oil pan, 22 overdrive brake band, 23 overdrive case, 24 input shaft, 25 overdrive cancel solenoid MAZDA

9.

What are the likely problems if the selector

linkage is not correctly adjusted?

10.

What is the purpose of the isolator or neutral

switch?

11.

12.

How can the operation of the isolator switch be

checked?

What is the purpose of the throttle cable and

what does it operate?

13.

How would incorrect adjustment of the throttle

cable affect transmission operation?

14.

What is the purpose of a vacuum control?

15.

When is a throttle-position sensor used?

16.

Generally, how is a band adjustment carried

out?

17.

What would be the effect of a faulty band

adjustment?

18.

What are some of the basic checks that should

be carried out if an automatic transmission is not

operating properly?

19.

What is meant by diagnosis?

20.

What is the function of the road-speed sensor?

21.

State the main checks that would be made during

the road test of an automatic transmission.

22.

How could the parking pawl be checked?

23.

What are the power mode and economy mode?

24.

What is adaptive learning strategy as applied to

the shift pattern of an automatic transmission?

25.

Name the different sections of an automatic

transmission that would be considered when

locating a fault.

481-506_May 2chap 24

13/9/06

4:15 PM

Page 504

504 part four automatic transmissions and drive

figure 24.31

Sectional view of an automatic transaxle

1 transaxle case, 2 rear clutch, 3 front clutch, 4 connecting shell, 5 front ring gear, 6 front planet carrier, 7 sun

gear, 8 low and reverse brake, 9 one-way clutch, 10 one-way clutch inner race, 11 rear planet carrier, 12 rear ring gear and

hub assembly, 13 bearing housing, 14 output gear, 15 turbine shaft, 16 oil pump shaft, 17 bearing cover, 18 oil seal, 19 torque

converter, 20 converter housing, 21 oil seal, 22 speedometer drive gear, 23 side gear, 24 pinion, 25 pinion shaft, 26 differential

gear case, 27 final-drive gear, 28 oil seal, 29 side-bearing housing, 30 control valve assembly, 31 oil pan, 32 oil pump, 33 band

FORD

481-506_May 2chap 24

13/9/06

4:15 PM

Page 505

chapter twenty-four automatic transmission service

figure 24.32

505

Four-speed automatic transaxle in part section

1 coasting clutch, 2 forward clutch, 3 reverse clutch, 4 reverse and forward drum, 5 3–4 clutch, 6 2–4 brake

band, 7 low and reverse brake, 8 output gear, 9 idler gear, 10 differential, 11 parking pawl, 12 throttle cable, 13 control body,

14 oil pump, 15 inhibitor switch, 16 pulse generator, 17 fluid-temperature switch MAZDA