Programmable Controllers an engineer guide P1

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (1.1 MB, 30 trang )

Programmable Controllers

075065757X-ch000-prelims.fm Page i Saturday, June 28, 2003 4:46 PM

In memory of Arthur Parr, 1913–1992.

Man is still the most extraordinary computer of all.

John F. Kennedy

21 May 1963

075065757X-ch000-prelims.fm Page ii Saturday, June 28, 2003 4:46 PM

Programmable Controllers

An engineer’s guide

Third edition

E.A. Parr, MSc, CEng, MIEE, MInstMC

AMSTERDAM BOSTON HEIDELBERG LONDON NEW YORK OXFORD

PARIS SAN DIEGO SAN FRANCISCO SINGAPORE SYDNEY TOKYO

Newnes

075065757X-ch000-prelims.fm Page iii Saturday, June 28, 2003 4:46 PM

Newnes

An imprint of Elsevier

Linacre House, Jordan Hill, Oxford OX2 8DP

200 Wheeler Road, Burlington, MA 01803

A division of Reed Educational and Professional Publishing Ltd

A member of the Reed Elsevier plc group

First published 1993

Second edition 1999

Third edition 2003

Copyright © E.A. Parr 1993, 1999, 2003. All rights reserved.

The right of E.A. Parr to be identified as the author of this work

has been asserted in accordance with the Copyright, Designs and

Patents Act 1988

No part of this publication

may be reproduced in any material form (including

photocopying or storing in any medium by electronic

means and whether or not transiently or incidentally

to some other use of this publication) without the

written permission of the copyright holder except

in accordance with the provisions of the Copyright,

Designs and Patents Act 1988 or under the terms of a

licence issued by the Copyright Licensing Agency Ltd,

90 Tottenham Court Road, London, England W1T 4LP.

Applications for the copyright holder’s written permission

to reproduce any part of this publication should be addressed

to the publishers

British Library Cataloguing in Publication Data

A catalogue record for this book is available

from the British Library

ISBN 0 7506 5757 X

Typeset by Integra Software Services Pvt. Ltd, Pondicherry, India

www.integra-india.com

Printed and bound in Great Britain

For information on all Newnes publications visit our website at:

newnespress.com

075065757X-ch000-prelims.fm Page iv Saturday, June 28, 2003 4:46 PM

Contents

Preface xi

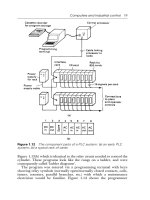

1 Computers and industrial control

1

1.1 Introduction 1

1.2 Types of control strategies 1

1.2.1 Monitoring subsystems 2

1.2.2 Sequencing subsystems 2

1.2.3 Closed loop control subsystems 4

1.2.4 Control devices 5

1.3 Enter the computer 6

1.3.1 Computer architectures 7

1.3.2 Machine code and assembly language programming 11

1.3.3 High level languages 11

1.3.4 Application programs 14

1.3.5 Requirements for industrial control 14

1.3.6 The programmable controller 18

1.4 Input/output connections 21

1.4.1 Input cards 21

1.4.2 Output connections 22

1.4.3 Input/output identification 28

1.5 Remote I/O 29

1.6 The advantages of PLC control 31

075065757X-ch000-prelims.fm Page v Saturday, June 28, 2003 4:46 PM

vi Contents

2 Programming techniques 33

2.1 Introduction 33

2.2 The program scan 36

2.3 Identification of input/output and bit addresses 40

2.3.1 Racks, cards and signals 40

2.3.2 Allen Bradley PLC-5 41

2.3.3 Siemens SIMATIC S5 42

2.3.4 CEGELEC GEM-80 42

2.3.5 ABB Master 45

2.3.6 Mitsubishi F2 47

2.3.7 Internal bit storage 48

2.4 Programming methods 48

2.4.1 Introduction 48

2.4.2 Ladder diagrams 49

2.4.3 Logic symbols 52

2.4.4 Statement list 55

2.5 Bit storage 58

2.6 Timers 63

2.7 Counters 67

2.8 Numerical applications 72

2.8.1 Numeric representations 72

2.8.2 Data movement 75

2.8.3 Data comparison 77

2.8.4 Arithmetical operations 78

2.9 Combinational and event-driven logic 81

2.9.1 Combinational logic 81

2.9.2 Event-driven logic 86

2.10 Micro PLCs 95

2.11 IEC 1131-3, towards a common standard 99

2.12 Programming software 105

2.13 Programming software tools 109

3 Programming style

115

3.1 Introduction 115

3.2 Software engineering 116

3.3 Top-down design 118

075065757X-ch000-prelims.fm Page vi Saturday, June 28, 2003 4:46 PM

Contents vii

3.4 Program structure in various PLCs 119

3.5 Housekeeping and good software practice 128

3.6 Speeding up the PLC scan time 135

4 Analog signals, closed loop control

and intelligent modules 140

4.1 Introduction 140

4.2 Common analog signals 140

4.2.1 Temperature 140

4.2.2 Pressure 142

4.2.3 Flow 144

4.2.4 Speed 146

4.2.5 Weighing systems 146

4.2.6 Level 147

4.2.7 Position 148

4.2.8 Output signals 149

4.3 Signals and standards 149

4.4 Analog interfacing 151

4.4.1 Resolution 151

4.4.2 Multiplexed inputs 152

4.4.3 Conversion times 153

4.4.4 Channel selection and conversion to engineering units 156

4.4.5 Analog input cards 158

4.4.6 Filtering 160

4.5 Analog output signals 160

4.6 Analog-related program functions 163

4.7 Closed loop control 164

4.7.1 Introduction to control theory 164

4.7.2 Stability and loop tuning 167

4.7.3 Closed loop control and PLCs 168

4.8 Specialist control processors 172

4.9 Bar codes 173

4.10 High-speed counters 178

4.11 Intelligent modules 178

4.12 Installation notes 179

075065757X-ch000-prelims.fm Page vii Saturday, June 28, 2003 4:46 PM

viii Contents

5 Distributed systems 182

5.1 Parallel and serial communications 182

5.2 Serial standards 185

5.2.1 Introduction 185

5.2.2 Synchronization 185

5.2.3 Character codes 186

5.2.4 Transmission rates 186

5.2.5 Modulation of digital signals 189

5.2.6 Standards and protocols 191

5.2.7 Error control 196

5.2.8 Point to point communication 202

5.3 Area networks 205

5.3.1 Introduction 205

5.3.2 Transmission lines 205

5.3.3 Network topologies 207

5.3.4 Network sharing 209

5.3.5 A communication hierarchy 210

5.4 The ISO/OSI model 212

5.5 Proprietary systems 214

5.5.1 Introduction 214

5.5.2 Allen Bradley Data Highway 215

5.5.3 Gem-80 Starnet, ESP and CORONET 217

5.5.4 Siemens SINEC 218

5.5.5 Ethernet 218

5.5.6 Towards standardization 219

5.5.7 Profibus 223

5.6 Safety and practical considerations 224

5.7 Fibre optics 227

6 The man–machine interface 232

6.1 Introduction 232

6.2 Simple digital control and indicators 234

6.3 Numerical outputs and inputs 236

6.3.1 Numerical outputs 236

6.3.2 Multiplexed outputs 237

6.3.3 Leading zero suppression 240

6.3.4 Numerical inputs 240

6.4 Alarm annunciation 242

075065757X-ch000-prelims.fm Page viii Thursday, July 3, 2003 3:59 PM

Contents ix

6.5 Analog indication 247

6.6 Computer graphics 250

6.6.1 Introduction 250

6.6.2 The Allen Bradley Panelview 254

6.6.3 Pixel graphics; the CEGELEC Imagem 256

6.6.4 The Siemens Simatic HMI family 265

6.6.5 Practical considerations 267

6.6.6 Data entry 270

6.7 Message displays 271

6.8 SCADA packages 271

7 Industrial control with conventional computers 276

7.1 Introduction 276

7.2 Bus-based machines 277

7.2.1 Introduction 277

7.2.2 IEEE-488 parallel interface bus 278

7.2.3 Backplane bus systems 281

7.2.4 IBM PC clones 282

7.3 Programming for real time control 285

7.4 Soft PLCs 292

8 Practical aspects 293

8.1 Introduction 293

8.2 Safety 293

8.2.1 Introduction 293

8.2.2 Risk assessment 294

8.2.3 PLCs, computers and safety 296

8.2.4 Emergency stops 308

8.2.5 Guarding 312

8.2.6 Safety legislation 314

8.2.7 IEC 61508 315

8.3 Design criteria 320

8.4 Constructional notes 322

8.4.1 Power supplies 322

8.4.2 Equipment protection 325

8.5 Maintenance and fault finding 331

8.5.1 Introduction 331

8.5.2 Statistical representation of reliability 332

075065757X-ch000-prelims.fm Page ix Saturday, June 28, 2003 4:46 PM

x Contents

8.5.3 Maintenance philosophies 335

8.5.4 Designing for faults 337

8.5.5 Documentation 339

8.5.6 Training 344

8.5.7 Fault-finding aids, EDDI and FIMs 348

8.6 Electromagnetic compatibility (EMC)

and CE marking 354

8.7 Other programmable devices 359

9 Sample ladder logic 362

9.1 Introduction 362

9.2 One Shot 364

9.3 Toggle action 365

9.4 Alarm annunciator 368

9.5 First order filter 370

9.6 Level control 373

9.7 Linearization 380

9.8 Flow totalization 385

9.9 Scaling 391

9.10 Gray code conversion 394

9.11 BCD to Binary conversion 398

9.12 Binary to BCD conversion 400

9.13 A hydraulic system 403

Appendix Number systems 416

Index 421

075065757X-ch000-prelims.fm Page x Saturday, June 28, 2003 4:46 PM

Preface

All industrial processes need some form of control system if they are to

run safely and economically. In recent years a specialist control computer,

called a programmable controller, has evolved and revolutionized control

engineering by combining computing power and immense flexibility at

a reasonable price.

This book is concerned with the application and use of programmable

controllers. It is not an instructional book in programming, and is certainly

not a comparative guide to the various makes of machine on the market.

To some extent, choosing a programmable controller is rather like

choosing a word processor. You ask people for their views, try a few

simple examples in a shop, and buy the cheapest that you think meets

your requirements. Only after several months do you really know the

system. From then on, all other word processors seem awkward.

Programmable controllers are similar. Unless there are good reasons

for a particular choice (ready experience in the engineering or maintenance

staff, equipment being supplied by an outside contractor and similar

considerations), there are good and bad points with all (the really bad

machines left the market years ago).

At the Sheerness Steel Company where I work, the plant control is

based on about sixty programmable controllers consisting of Allen

Bradley PLC 2s and 5s, GEC (now CEGELEC) GEM-80s, ASEA (now

ABB) Masters and Siemens SIMATIC S5s, with small machines primar-

ily from Mitsubishi. These controllers are somewhat like the trees at

Galleons Lap in Winnie the Pooh; there never seems to be the same

number on two successive days, even if you tie a piece of string around

each one!

As with most plants, the background to this distribution of controllers

is largely historical chance (the original Mitsubishi came on a small

turn-key plant from an outside contractor, for example), but the ready

access to these machines is the reason for their prominence in this book.

075065757X-ch000-prelims.fm Page xi Saturday, June 28, 2003 4:46 PM

xii Preface

Even within this range of PLC families, the coverage in this book is

not complete. The PLCs have been chosen to cover the application points

I wish to make, not as a complete survey of a manufacturer’s range.

In ‘previous lives’ I have worked with PLCs from AEG, GE, Landys

and Gyr, Modicon, Telemecanique, Texas Instruments and many other

companies. To these manufacturers I offer my sincere apologies for not

giving them more coverage, but to do so would have made a tedious book

and masked the application points I have tried to make. I could happily

use any of these machines, and there is not a major difference in style or

philosophy between them (the manufacturers would no doubt disagree!).

The guideline is therefore choose a machine that suits you, and do not

change manufacturers for purely economic reasons. Knowledge, consistency

of spares and a good relationship with a manufacturer are very valuable.

A book like this requires much assistance, and I would like to thank

Peter Bark and Dave Wilson of ABB, Adrian Bishop, Bob Hunt, Julian

Fielding, John Hanscombe, Hugh Pickard, Jennie Holmes and Hennie

Jacobs of Allen Bradley, Peter Backenist, David Slingsby and Stuart

Webb of GEC/CEGELEC, Peter Houldsworth, Paul Judge, Allan

Norbury, Dickon Purvis, Paul Brett and Allan Roworth of Siemens,

and Craig Rousell who all assisted with information on their machines,

commented constructively on my thoughts and provided material and

photographs.

My fellow engineers at Sheerness Steel also deserve some praise for

tolerating my PLC systems (and who will no doubt compare my written

aims with our actual achievements!).

A book takes some time to write, and my family deserve considerable

thanks for their patience.

Andrew Parr

Minster on Sea

Note for second edition

This revision incorporates additional material covering recent develop-

ments, and reflects the increasing importance of health and safety

legislation.

Notes for third edition

This edition includes a new chapter giving example ladder rungs for

common industrial problems. Screen shots of Windows based program-

ming software have been included to show how programs are entered.

Health and Safety issues, particularly the introduction of IEC 61508,

have been updated.

075065757X-ch000-prelims.fm Page xii Saturday, June 28, 2003 4:46 PM