Bsi bs au 266 1 1996 (1999) iso 11154 1 1995

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (789.42 KB, 18 trang )

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BRITISH STANDARD AUTOMOBILE SERIES

Specification for

Roof load carriers —

Part 1 : Roof bars

BS AU 266-1 :

1 996

ISO 1 1 1 5 4-1 :

1 995

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 266-1 :1 996

Committees responsible for this

British Standard

The preparation of this British Standard was entrusted to Technical

Committee AUE/9, Automobile details and accessories, upon which the

following bodies were represented:

Automobile Association

BSI Testing Services

Consumer Policy Committee of BSI

Department of Trade and Industry (Consumer Safety Unit, CA Division)

Department of Transport

Garage Equipment Association

Institute of Trading Standards Administration

Society of Motor Manufacturers and Traders Limited

This British Standard, having

been prepared under the

direction of the Engineering

Sector Board, was published

under the authority of the

Standards Board and comes

into effect on

Amendments issued since publication

1 5 March 1 996

© BSI 09- 1 999

The following BSI references

relate to the work on this

standard:

Committee reference AUE/9

Draft for comment 93/71 6275 DC

ISBN 0 5 80 25 5 04 2

Amd. No.

Date

Comments

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 266-1 :1 996

Contents

Page

Committees responsible

Inside front cover

National foreword

ii

1

Scope

1

2

Normative references

1

3

Definitions

1

4

Symbols and units

2

5

Requirements

2

6

Test methods

3

7

Instructions for use and fitting

4

8

Marking

5

Annex A (normative) Approval/rej ection procedure

11

Annex B (normative) Tightening torques for fixing roof bars

12

Annex C (informative) Determination of allowable additional mass

12

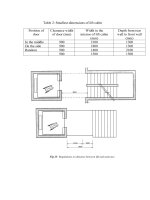

Figure 1 — Components of roof bar

5

Figure 2 — Components of connecting devices

5

Figure 3 — Test box

6

Figure 4 — Test box location and strapping

7

Figure 5 — Deflection measuring point

8

Figure 6 —

9

F application point

Figure 7 — F application point

Figure 8 — F and 0, 5 F application points

l

lq

a

List of references

© BSI 09- 1 999

a

9

10

Inside back cover

i

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 266-1 :1 996

National foreword

This British Standard has been prepared by Technical Committee AUE/9. It is

identical with ISO 1 1 1 54- 1 : 1 995

Part 1: Roof bars ,

Road vehicles — Roof load carriers —

published by the International Organization for

Standardization (ISO).

It is anticipated that additional parts to this standard will be published, as

follows, when the corresponding ISO standards have been completed:

Part 2: Accessories and attachments to roof bars for special purpose

applications ;

—

—

Part 3: Specific purpose roof devices .

Cross-references

International Standard

Corresponding British Standard

ISO 9227: 1 990

BS 7479: 1 991

Method for salt spray corrosion tests in

artificial atmospheres

(Identical)

The Technical Committee has reviewed the provisions of ISO 61 2: 1 978 and

ISO 1 1 76: 1 990, to which reference is made in the text, and has decided that they

are acceptable for use in conj unction with this standard.

A British Standard does not purport to include all the necessary provisions of a

contract. Users of British Standards are responsible for their correct application.

Compliance with a British Standard does not of itself confer immunity

from legal obligations.

Summary of pages

This document comprises a front cover, an inside front cover, pages i and ii,

pages 1 to 1 2, an inside back cover and a back cover.

This standard has been updated (see copyright date) and may have had

amendments incorporated. This will be indicated in the amendment table on the

inside front cover.

ii

© BSI 09- 1 999

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 2 66-1 : 1 996

1 S cope

3 Definitions

This part of ISO 1 1 1 54 specifies the minimum

For the purposes of this part of ISO 1 1 1 54, the

safety requirements for roof bars intended for

following definitions apply.

mounting on or above the roofs of passenger cars or

light commercial vehicles with a maximum

authorized total mass (ISO- M08) as defined in

ISO 1 1 76 up to 3, 5 t.

It applies to general- use roof bars suitable for

carrying load, excluding magnetic and vacuum- fixed

devices (see note 1 ).

3.1

roof bar

supporting bar with connecting devices which

enables a load to be carried on the roof of a vehicle

NOTE 2

NOTE 3

It establishes technical specifications and test

methods which offer both the user of roof bars and

road users a minimum level of safety when the roof

Generally, roof bars are compatible with the use of

additional accessories.

Roof bars are fixed on the roof or on original- equipment

rails of the vehicle.

NOTE 4

An example of components of a roof bar is given

in Figure 1 .

bars are being used in accordance with the

3.2

manufacturer’s instructions.

connecting de vice

Moreover, requirements of ISO 1 1 1 54 complete the

provisions of Directive 74/483/EEC

1)

concerning

NOTE 5

these products.

NOTE 1

set of parts connecting the supporting bar to the

vehicle

The other parts of ISO 1 1 1 54 are as follows:

Examples of connecting device components are given

in Figure 1 and Figure 2.

— part 2 covers additional accessories intended to be fitted on

3.3

general purpose roof bars;

spe cific purpose roof device

— part 3 covers specific purpose roof devices;

— part 4 covers magnetic and vacuum- fixed devices.

roof device designed for a specific type of load or use

3.4

2 Normative references

additional acce ssory

The following standards contain provisions which,

device used in conj unction with the roof bars to

through reference in this text, constitute provisions

carry a specific type of load

of this part of ISO 1 1 1 54. At the time of publication,

the editions indicated were valid. All standards are

subj ect to revision, and parties to agreements based

3.5

maximum ve hicle roof load,

m

d

on this part of ISO 1 1 1 54 are encouraged to

maximum load capacity permissible on the roof of

investigate the possibility of applying the most

the vehicle as defined by the vehicle manufacturer

recent editions of the standards indicated below.

3.6

Members of IEC and ISO maintain registers of

maximum roof b ar set load,

currently valid International Standards.

ISO 61 2: 1 978,

Ro ad v ehicles — Dim ens ions of m o to r

m

b

maximum load capacity permissible on roof bar set

as defined by the roof bar manufacturer

v ehicles and tow ed v ehicles — Term s and

3.7

definitions.

mass of se t of roof b ars,

ISO 1 1 76: 1 990,

Ro ad v ehicles — Mass es —

Vocab ulary and codes.

ISO 9227: 1 990,

Corrosio n tes ts in artificial

atm os p heres — Salt s p ray tests.

European Commission Directive 79/488/EEC

/

/

3.8

the ore tical maximum load,

m

maximum vehicle roof load

minus mass of set of

m

Directiv e 74 483 EEC on the ap p ro xim ation of the

3.9

actual maximum load,

, 1 8 April 1 979.

1)

European Council Directive 74/483/EEC on the

p ro jections o f m o to r v ehicles

© BSI 09- 1 999

m

theoretical maximum load,

bar load,

m

m

d

n

e

law s of the Mem b er States relating to the external

p rojections of m otor v ehicles

e

total mass of set of roof bars

roof bars

adap ting to technical p rogres s Co uncil

m

x

m

n,

or maximum roof

b , whichever is the lowest

ap p ro xim atio n o f th e law s of the Mem b er States relating to the external

, 1 7 September 1 974.

1

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 2 66-1 : 1 996

3.1 0

5 . 2 Slide re sistance under quasi-static force

d

de fle ction,

app lie d at 2 0 ° to ve hicle longitudinal axis

sum of permanent deformations and sliding

5.2.1

displacement of a roof bar when fixed to a vehicle

deflection

roof and under test conditions

application of a force 0, 5

3.1 1

5.2.2

test b ox

deflection

When tested in accordance with

d

3

lq .

4

6. 3 ,

the

shall not exceed 50 mm under the

application of a force

load simulation device used during the test

the

F

When tested in accordance with

d

6. 3 ,

shall not exceed 1 0 mm under the

F

lq .

5 . 3 Re sistance to lift

3.1 2

lifting force ,

F

When used in accordance with the manufacturer’s

a

force applied during testing to simulate the vertical

component of the aerodynamic effect of load

instructions, roof bars shall be able to withstand

those lifting forces which can be expected to occur.

When tested in accordance with

3.1 3

forward longitudinal force ,

F

force

l

6. 4 ,

under a

F , the roof bars shall remain fixed on the roof.

a

If front and rear connecting devices are different,

force applied during testing to simulate the

horizontal forward component of the force caused by

the load

the rear roof bar shall remain fixed to the roof under

a force 0, 5

F

a

when tested in accordance with

6. 4 .

5 . 4 Re sistance to corrosion

3.1 4

2 0 ° horizontal force ,

F

When tested in accordance with

lq

force applied during testing to simulate the effect

caused by the load during braking when cornering

6. 5 ,

no active

corrosion which affects the basic function of each

part shall appear after the test.

5 . 5 Re sistance of mate rials

4 Symbols and units

All materials shall allow roof bars to fulfil the

For the purposes of this part of ISO 1 1 1 54, the

following symbols and units apply.

S ymb ol

requirements specified in

5.1

at outside

into account ultraviolet stability and ozone ageing.

This shall be shown by at least one of the following

Unit

d

Maximum vehicle roof load

kg

b

Maximum roof bar set load

kg

that material property concepts are compatible

e

Mass of set of roof bars

kg

with intended use,

n

Theoretical maximum load

kg

x

Actual maximum load

kg

Deflection

mm

a

Lifting force

N

l

Forward longitudinal force

N

limited to the width of the vehicle roof panel

lq

20 ° horizontal force

N

(see Figure 5). However, the length of the bar shall

methods

a) materials certification

b) tests as in clause

6

2)

showing

c) reference to applicable standards.

5 . 6 O ve rhang and e xte rnal shap e

It is recommended that the bar length be

not exceed the vehicle width as defined in

ISO 61 2: 1 978,

5 . 6. 2

6. 2 .

The external radius of all contactable

components shall conform to

ap plied forward in ve hicle longitudinal axis

Directive 79/488/EEC.

When tested in accordance with

deflection

d

1

d

2

and

6. 1 6. 3

of

the

F.

l

When tested in accordance with

deflection

6. 2 ,

6. 1 6. 2

shall not exceed 1 0 mm under the

application of a force 0, 5

5.1.2

2)

under the limiting

5 . 1 S lide re sistance unde r quasi-static force

5.1 .1

or reports

conditions given above,

5 . 6. 1

5 Requirements

6. 2 ,

the

shall not exceed 50 mm under the

application of a force

2

5.3

D e signation

m

m

m

m

m

d

F

F

F

2)

to

temperatures between – 20 ° C and + 60 °C, taking

F.

l

Reference may be made to the ISO 9000 series of International Standards for these documents.

© BSI 09- 1 999

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 266-1 :1 996

6 Test methods

6.2 Slide resistance test under quasi-static

forward force

6.1 General

6.1 .1 All slide resistance and resistance to lift tests

shall b e carried out on the vehicle roof in the

following sequence:

b) slide resistance test under a quasi- static

forward force

F

l

;

c) slide resistance test under a quasi- static force

F

lq

The nominal value of the longitudinal forward force,

F

l

a) resistance to lift test;

at 2 0 ° to the vehicle longitudinal axis.

Three roof b ars sets manufactured from current

production tools shall be made available as test

Nominal value of force

6.2.1

, is given b y the equation:

F

l

= 40

where

m

m

=

x

=

x

m

m

m

x

if

b

if

n

m

m

b

b

<

>

m

m

n

n

Test procedure

6.2.2

Mount the roof b ars on the roof of the vehicle.

specimens.

Tighten the clamps to the required torque or force

The approval/rej ection procedure shall be as

and record the value.

specified in Annex A.

Install the test b ox, weighted to the

6.1 .2 Roof bars shall b e tested in pairs unless they

clamp it as indicated in 6.1 .6 .

m

x

value, and

are specifically designed to b e used in sets of more

Check and, if necessary, readj ust the clamps to the

than two.

specified torque or force value.

6.1 .3 Adj ustable roof bars shall b e tested at their

Install the measuring equipment as shown

maximum height above the roof.

in Figure 5.

6.1 .4 Prior to each test each set of b ars shall be

Progressively and continuously apply the

fitted, released and retightened to the specified

longitudinal force

instructions.

required nominal value, checking the instant

d

F

at 0, 5

l

F

as shown in Figure 6 up to the

. Immediately release the force,

Fitting and tightening torques shall be in

deflection

accordance with the manufacturer’s instructions or,

and measure and record the total deflection

failing that, in accordance with Annex B.

6.3 Slide resistance test under quasi-static

6.1 .5 The distance b etween the roof b ars shall be as

force at 20 ° to longitudinal axis

specified in the instructions for fitting and use.

6.1 .6 The test box shall b e in accordance

with Figure 3 and shall not b e deformed b y the load.

The ballast used to adj ust the mass shall b e

uniformly distrib uted in the test box.

The test mass

of

±

m

x

shall be adj usted to an accuracy

1 kg.

The test box shall be firmly attached to the roof

bars, as shown in Figure 4, using straps to preclude

any movement between the bars and the test b ox.

For sets with more than two bars, the test b ox shall

a) from the first to the second, and then

b) from the second to the third bar, etc.

6.1 .7 Test forces shall be applied to achieve the

maximum value within 1 5 s to 30 s, to a tolerance

of

0

N.

6.1 .8 The deflection,

l

Nominal value of force

6.3.1

The nominal value of the 2 0 ° force,

F

lq

d

2

.

, is given b y

the equation:

F

= 40

lq

where

m

m

x

=

x

=

6.3.2

m

m

m

x

b

if

n

if

m

m

b

<

b

>

m

m

n

n

Test procedure

Mount the roof b ars on the roof of the vehicle.

Tighten the clamps to the required torque or force

be attached, in turn:

+1 00

1

and record the value.

Install the test b ox, weighted to the

m

x

value, and

clamp it as indicated in 6.1 .6 .

Check and, if necessary, readj ust the clamps to the

specified torque or force value.

d

, shall b e measured in

accordance with Figure 5.

Install the measuring equipment as shown

in Figure 5.

Progressively and continuously apply the 2 0 °

force

F

lq

as shown in Figure 7 up to the required

nominal value, checking the instant deflection

at 0, 5

F

lq

measure and record the total deflection

© BSI 09- 1 999

d

3

. Immediately release the force, and

d

4

.

3

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 266-1 :1 996

6.4 Resistance to lift test

7.2 Instructions for use

Test force

The roof bar manufacturer shall provide

instructions for use containing the following

The force Fa shall be applied to the connecting

minimum

information:

devices between roof bars and vehicle roof, up to the

a) Value of actual maximum load on the roof

maximum value determined by the following

bars for the vehicle(s) for which it is made and,

equation:

a warning regarding relevant regulations

m

Fa = 2 500 + x × g

(an example is given in Annex C).

2

b) the following information:

where g is the2 acceleration due to gravity

1) The load shall be as evenly distributed as

(g = 9,81 m/s ).

possible over the area of the carrier system,

6.4.2 Test procedure

and the centre of gravity of the load kept as low

Mount the roof bars on the roof of the vehicle.

as possible. Narrow and heavy loads

(for example, metal tubes) are to be carried

Tighten the clamps to the required torque or force

near the feet of the carrier system. Loads

and record the value.

which overhang the ends of the carrier system

Install the test box, weighted to the m x value, and

shall conform to any relevant laws or by-laws

clamp it as indicated in 6.1 .6.

in

force, and shall be adequately secured.

Check and, if necessary, readjust the clamps to the

2) Loads shall be adequately secured using

specified torque or force value.

suitable straps or similar tightening devices.

Progressively and continuously apply a vertical

After

loading, recheck the security of the load

lifting force Fa across the test box as shown

and

roof

bars regularly throughout the

in Figure 8, up to the nominal value.

journey. Elastic straps with securing hooks

Maintain this force for 10 min.

shall not be used.

Release the force.

3) Where surfboards are carried (or similar

items which may produce lifting forces), they

If front and rear connecting devices are different,

shall not be carried side-by-side, but stacked

apply a vertical lifting force at the rear of the test

one

upon the other. All surfboards and similar

box equal to 0,5Fa, with the same test method, as

items

shall be secured independently to the

shown in Figure 8.

front

and

rear of the vehicle using straps or

6.5 Resistance to corrosion test

other methods which are capable of

Expose the roof bars to the neutral salt spray test

with-standing the lifting forces.

(NSS) with 5 % of sodium chloride for 192 h. Expose

4) Where specialized accessories are available

the functional parts to this salt spray for 400 h.

to carry or secure loads, for example cycle

These tests shall be performed in accordance with

carriers, it is recommended that they are used.

ISO 9227.

5) The handling characteristics of a vehicle will

change when a carrier system is fitted and

7 Instructions for use and fitting

especially when it is loaded (in particular,

7.1 Fitting instructions

crosswind sensitivity, handling on bends, and

braking).

Driving techniques should be altered

The roof bar manufacturer shall give the following

to allow for these changes, reducing speed,

information in the assembly instructions:

especially on bends, and allowing for longer

a) detailed fitting instructions with figures or

braking distances.

illustrations;

6) To reduce fuel consumption, it is

b) the value of the torque or force where it is

recommended that the roof bars be removed

necessary to apply a specified torque or force to a

after use.

fastening device in order to fix the roof bars to a

c) a warning explaining:

vehicle;

1) the importance of correctly following the

c) a recommendation to have approximate

instructions for fitting and use;

spacing between bars of 700 mm or that specified

by the vehicle manufacturer;

2) the need for the fixing devices to be

tightened correctly and checked regularly

d) mounting points on the type(s) of vehicle(s) for

during the journey;

which the roof bars are intended and a warning

that roof bars must not be used on vehicles other

3) that loads are carried within the limitations

than those specified by the manufacturer.

of 7.2 a) and 7.2 b) 1);

6.4.1

4

© BSI 09-1999

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 266-1 :1 996

4) that loads are secured correctly and safely;

5) that equipment must b e maintained in good

working order.

8 Marking

Roof bars shall have the following marking:

a) name or trademark of the manufacturer,

importer or distrib utor;

b ) type of bar;

c) maximum roof b ar load defined in accordance

with this part of ISO 1 1 1 54;

d) a reference to ensure traceab ility.

1 ) See Figure 2.

Figure 1 — Components of roof bar

Figure 2 — C omponents of connecting devices

© BSI 09- 1 999

5

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 266-1 :1 996

1 ) If the distance b etween outside roof bars is more than 900 mm, the test box length

shall be equal to this distance plus 1 00 mm.

Figure 3 — Test box

6

© BSI 09- 1 999

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 266-1 :1 996

1 ) In accordance with mounting instructions or 700 mm b y default.

Figure 4 — Test box location and strapping

© BSI 09- 1 999

7

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 266-1 :1 996

Figure 5 — Deflection measuring point

8

© BSI 09- 1 999

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 266-1 :1 996

NO TE

The force is ap p lied in the direction of vehicle movem ent, at the centre of the tes t b ox front face.

Figure 6 —

Figure 7 —

© BS I 0 9- 1 99 9

F

l

F

lq

application point

application point

9

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 266-1 :1 996

Figure 8 —

10

F

a

and

0, 5

F

a

application points

© BS I 0 9 - 1 99 9

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 266-1 :1 996

Annex A (normative)

Approval/rej ection procedure

© BSI 09- 1 999

11

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 266-1 :1 996

Annex B (normative)

Tightening torques for fixing roof bars

Torque

Type of fixing

N·m

Hand nut/screw diameter less than 35 mm

2

Hand nut/screw diameter 35 mm to less than 45 mm

3

Hand nut/screw diameter 45 mm to less than 55 mm

4

Hand nut/screw diameter 55 mm to less than 65 mm

5

Slotted head screw M6

3

Slotted head screw M8

4

a

CHC, VH, TORX M6 screw

5

CHC, VH, TORXa M8 screw

6

Hexagon nut M6

5

Hexagon nut M8

6

Butterfly nut M6

2

Butterfly nut M8

3

a

TORX is a trade- name. This information is given for the convenience of users of this International Standard and does not

constitute an endorsement by ISO of the product named. Equivalent products may be used if they can be shown to lead to the

same results.

Annex C (informative)

Determination of allowable additional mass

The maximum load to be carried on roof bars shall be limited such that

— the maximum allowable mass on the vehicle roof,

— the maximum allowable mass on the set of roof bars, and

— the maximum total mass of the vehicle,

are not exceeded.

Calculation examples are given below.

Values in kilograms

Ref.

a

Items to be considered

Maximum allowable mass on the vehicle roof defined

Example No. 1

Example No. 2

Example No. 3

60

75

1 00

350

500

650

75

50

1 00

300

380

450

10

5

20

0

50

75

a – e

50

70

80

c

75

50

1 00

b – (d + e + f)

40

65

1 05

40

50

80

by the vehicle manufacturer

b

Payload (as defined by vehicle manufacturer)

c

Maximum load which carrier system can accept

d

Assumed interior load (75 kg/passenger + luggage)

e

Mass of carrier system

f

Maximum allowable load on towing hook

g

Maximum allowable load on roof carrier system —

the lowest of the following calculated values:

that is

12

© BSI 09- 1 999

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 266-1 :1 996

List of references

See national foreword.

© BSI 09- 1 999

Li cen sed Copy: Lon d on Sou th Ban k U n i versi ty, Lon d on Sou th Ban k U n i versi ty, Sat Dec 09 02: 08: 52 G M T+00: 00 2006, U n con trol l ed Copy, (c) BSI

BS AU 266-1 :

1 996

ISO 1 1 1 5 4-1 :

BSI — British Standards Institution

1 995

BS I is the indep endent national b ody res p ons ib le for p rep aring

Britis h S tandards . It p res ents the UK view on s tandards in E urop e and at the

international level. It is incorp orated b y Royal C harter.

Revisions

Britis h S tandards are up dated b y amendment or revis ion. Us ers of

Britis h S tandards should make s ure that they p oss es s the latest amendments or

editions .

It is the constant aim of BS I to imp rove the quality of our p roducts and services .

We would b e grateful if anyone finding an inaccuracy or amb iguity while us ing

this Britis h S tandard would inform the S ecretary of the technical committee

res p ons ib le, the identity of which can b e found on the inside front cover.

Tel: 02 0 89 96 90 00. Fax: 02 0 89 96 7 40 0 .

BS I offers memb ers an individual up dating s ervice called PLUS which ens ures

that s ub s crib ers automatically receive the lates t editions of s tandards .

Buying standards

O rders for all BS I, international and foreign s tandards p ub lications s hould b e

addres s ed to C us tomer S ervices. Tel: 0 2 0 899 6 9 00 1 . Fax: 0 2 0 899 6 7001 .

In res p ons e to orders for international standards , it is BS I p olicy to sup p ly the

BS I imp lementation of thos e that have b een p ub lis hed as Britis h S tandards,

unless otherwis e requested.

Information on standards

BS I p rovides a wide range of information on national, E urop ean and

international standards through its Lib rary and its Technical H elp to E xp orters

S ervice. Various BS I electronic information s ervices are also availab le which give

details on all its p roducts and s ervices . C ontact the Information C entre.

Tel: 02 0 89 96 71 1 1 . Fax: 02 0 89 96 7 048.

S ub s crib ing memb ers of BS I are kep t up to date with s tandards develop ments

and receive sub s tantial discounts on the p urchase p rice of s tandards. For details

of thes e and other b enefits contact Memb ership Adminis tration.

Tel: 02 0 89 96 70 02 . Fax: 02 0 89 96 7 00 1 .

Copyright

C op yright s ub s is ts in all BS I p ub lications . BS I als o holds the cop yright, in the

UK, of the p ub lications of the internationalstandardization b odies . E xcep t as

p ermitted under the C op yright, D es igns and Patents Act 1 988 no extract may b e

rep roduced, s tored in a retrieval s ystem or transmitted in any form or b y any

means – electronic, p hotocop ying, recording or otherwis e – without p rior written

p ermis s ion from BS I.

This does not p reclude the free us e, in the cours e of imp lementing the standard,

of necess ary details such as s ymb ols, and size, typ e or grade designations. If thes e

details are to b e used for any other p urp os e than imp lementation then the p rior

written p ermiss ion of BS I must b e ob tained.

If p ermis sion is granted, the terms may include royalty p ayments or a licensing

agreement. D etails and advice can b e ob tained from the C op yright Manager.

BS I

3 89 C his wick H igh Road

London

W4 4AL

Tel: 02 0 89 96 70 7 0.