Cutting Tool Technology Industrial Handbook by Graham T Smith_5 pot

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (500.29 KB, 9 trang )

ponent’s strength and the mechanical strength of the

chip, illustrating that a complex metallurgical and cut-

ting tool geometric relationship exists whilst machin-

ing occurs.

In particular for turning operations, a convention-

ally-turned chip is a rather frail product of serrated

appearance (see Figs 25 and 34a and b). In order to

promote good chip-breaking tendencies, thus enabling

short elements to be formed, it is necessary to encour-

age this basic character by causing these serrations to

be as deep as possible and the chip sections in between

to be rigid. is chip occurrence causes the chip to be

inexible, which can then subsequently be broken.

ere are several distinct ways in which chips can then

be broken, these include:

•

Self-breaking – this is when the chip’s mechanical

strength is not great enough to hold the chip seg-

ments together and they consequently break upon

exiting the machining region (Fig. 31a),

•

Chip collision with the workpiece – as the chip is

steered towards an obstacle such as the workpiece’s

surface this provides the breaking force (see Figs.

33 and 34b),

•

Chip is stopped by the tool – here the chip-curling

behaviour comes into play, this being a function of

the: tool’s nose radius geometry, depth of cut and

feedrate employed (see Fig. 34 bottom le-hand

photograph), the latter two functions aecting the

chip cross-section, or chip thickness

31

.

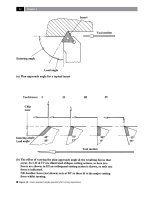

31 Chip thickness is inuenced by the plan approach angle

utilised and the D

OC

, in association with the selected feedrate.

e chip thickness is measured across the cutting edge, per-

pendicular to the cut (i.e. along the main cutting edge). e

chip width and thickness are the dimensions that dene the

theoretical cut of the edge into the workpiece material. Hence,

the chip thickness will vary with the size of the plan approach

angle according to the relationships involving: feedrate, D

OC

and the eective cutting depth. e chip thickness is related to

the plan approach angle and this aects the amount of pressure

bearing upon the cutting edge. Hence, the thinner the chip,

the smaller the distributed pressure along the edge and the less

power consumed, conversely, the thicker the chip, the greater

will be the machine tool’s power consumption. A thicker chip

is generally advantageous for an increased tool life, because of

the improved contact between the chip and its cutting edge.

Furthermore, if the plan approach angle is too small and chip

thickness is thin, this will reduce tool life, however, this can

be compensated for by increasing the feedrate, to produce a

thicker chip.

NB e helical formation of this chip-curling behav-

iour will shortly be mentioned, but prior to this, chip-

breakers/formers will be discussed.

.. Chip-Breakers and Chip-Formers

Chip-breakers have been utilised on turning tools for

many years, initially introduced in the 1940’s in the

form of an abutment, or step, situated behind the rake

face of the tool. Hence, with this type of early chip-

breaker, as the continuous chip moves across the rake

face it collides with this step and breaks. is origi-

nal form of chip-breaker geomtery was relatively in-

ecient as the resultant force direction changed with

the programmed tool path, this meant that the step

would be approached by the chip from diering di-

rections making chip-breaking less controlled. Such

chip-breakers were superseded in the 1970’s by in-

built ‘wavy-shaped’ chip-breakers sintered into the in-

sert’s top face (Fig 34 bottom le-hand photograph).

Recent developments in designing chip-breaker geom-

etries by computer-generated (i.e. CAD) techniques,

has shown a signicant step-forward in both chip-

former design enabling chip control and reduction in

frictional forces across the rake face at a range of cut-

ting data to be achieved. Such ‘automatic’ chip breaker

geometry forces the chip to deect at a narrower angle,

causing it to break o, either immediately, or just aer

the free end of the chip has hit either the tool’s ank or,

the workpiece before the rst coil has formed. If such

a collision does not take place, the result would be a

smaller diameter spiral chip and, it can be anticipated

that the chip would still break, but only when it be-

came slightly longer – this later chip breakage is due to

the increasing chip mass and the eect of gravity upon

it, with, or without any further collision.

Chip ow direction will depend upon several fac-

tors, such as the: chip-breaker prole, back rake and

setting angles, nose radius, D

OC

and feedrate – these

latter three factors require further discussion. e

relationship between the nose radius, D

OC

and feedrate

will oen change during vectored tool paths in any

machining operation. Even though the insert’s nose

radius is preset, its inuence on the chip direction

diers for dierent D

OC

’s, depending on how much

corner rounding is represented by the total engaged

edge length (Fig. 34c). Further, the feedrate also af-

fects the chip thickness: at dierent D

OC

’s and with a

constant feedrate, the form of chip cross-section (i.e.

Turning and Chip-breaking Technology

Figure 34. The principles of chip-breaking and chip-breaking envelopes for ‘coma-shaped swarf’ control and insert

edge preparations

.

Chapter

the ratio of chip width-to-thickness), will change and

this has a deleterious eect on the insert’s chip-break-

ing ability.

.. Helical Chip Formation

Conventional Turning

For the general turning operations, such as sliding (i.e.

Z-axis tool feeding) and facing (i.e. X-axis tool path

motions), the chip is rolled into a helix, simply because

the chip edges are formed from dierent rotation radii

(Fig. 34d). Here, the two edges of the chip consume

dierent quantities of workpiece material, creating dif-

fering edge lengths, coupled to the fact that a varia-

tion in cutting speed is present, these relationships will

result in a helical chip formation. e appearance of

the chip’s helix depends upon the workpiece’s diameter

and its metallurgical specication/condition, which

means the chip helices are extremely dicult to quan-

tify.

Most common types of helical chip diameters are

determined either directly by the initial curvature

from its origin, or are the result of additional bending,

introduced by the chip-breaker. For example, the heli-

cal chip type shown in Fig. 34c (le), has its chip seg-

ments turned inwards, this being a desirable chip form

when not fully developed, that is prior to the rst coil

being completed. Whether, or not the chip is of this

form will already be determined even before it meets

the chip-breaker, this being the result of its cross-sec-

tion and the natural tendency to bend according to the

‘line of least resistance’. If the chips width is no larger

than its thickness, for example, the resistance to bend-

ing in the segment-stiened thickness direction is

larger than in the width direction. In this case, unless

this kind of chip is broken early, by colliding with ei-

ther part of the tool, or the workpiece whilst it is still

sti and short – called ‘self-breaking’ – a helical chip

will be formed. In this case, the barbed, or serrated

edge is turned outwards causing additional bending,

this being introduced by the chip-breaker. For exam-

ple, the helical chip type shown in Fig. 34c (right),

becomes dicult and awkward to control. is out-

ward-curving helical chip also has weakened sections

in the serrations between the chip segments, but ap-

plied loads on it are readily absorbed by the spring ac-

tion of the chip. is type of chip will break as it hits

the insert’s ank face (see Fig. 27b)

32

. Only today’s very

complex chip-breaker designs can reduce these out-

ward-curling helical chips. Although such chip helices

produced by combinations of the feeds and D

OC

’s that

result in the chip width being too small in relation to

its thickness must be avoided.

Grooving and Recessing

In conventional turning operations, it is signicantly

easier to form a manageable chip, than for features re-

quiring either grooving, or recessing. e chip formed

during plunge grooving counter-rotates in relation

to the workpiece, whereby it does not experience the

same twisting force as chips produced by either Z-, or

X-axes turning operations. When grooving, ideally the

chip resembles a ‘watch spring’ , indicating that the chip

is curling back onto itself and will ultimately break in

several distinct ways: such as at the completion of the

grooving cycle, or due to friction between the chip and

its groove side walls – as the chip diameter becomes

greater. In grooving operations, three signicant fac-

tors aect chip control, these are:

(i)

Insert geometry – applied to the rake face, can be

classied into distinct groupings:

•

Radial-ground top rake (not shown), producing

the desired ‘watch-spring’ chip formation. is

grooving insert geometry will not thin the chip,

therefore surface nish passes are necessary on

both groove side walls.

NB For long-chipping materials the chip-former

does not provide enough resistance to produce chip

curling, hence, a straight at chip occurs, that may

32 One of the problems with this type of chip-breaking, is the

potential for secondary wear on the insert’s non-cutting zone

on the face, caused by the chip helix breaking locally against

this face. Such an occurrence happens when the chip helix at-

tains such a diameter and pitch that its free-end continually

strikes the non-cutting portion of the insert’s edge – termed

‘chip-hammering’ – causing the edge to be locally weakened

and to subsequently crumble.

NB Chip-hammering can be alleviated by slightly increasing

the helix diameter (i.e. by somewhat modifying the cutting

data) causing the chip to break against the tool’s ank – be-

low the insert’s cutting edge, this being one of the previously

employed and favoured chip-breaking mechanisms, as shown

in Fig. 27b.

Turning and Chip-breaking Technology

Figure 35. The chip-breaking envelopes related to cutting data and chip-curling behaviour. [Courtesy of

Sandvik Coromant]

.

Chapter

wrap itself around either the tool, or workpiece, but

such a geometry is perfect for machining alumin-

ium, or non-ferrous materials.

•

Radial top rake (illustrated in Fig. 4 middle and

to the le – three grooving insert sizes illustrated).

is radial top rake is designed to thin the chip.

Such chip thinning, eliminates the need to under-

take nishing passes on the groove’s side walls. Fur-

thermore, this type of grooving insert geometry be-

ing on-centre, enables axial turning of diameters for

wide shallow grooves

33

, or recesses.

•

Raised bumps on top rake (see Fig. 27a – le).

is sophisticated grooving geometry is utilised for

materials where chip control is dicult, as it pro-

vides an ‘aggressive barrier’ to the curling chip. e

raised bumps force the chip back onto itself, either

producing a tightly curled watch-spring chip, or

causes the chip to break.

(ii)

Surface speed of the workpiece – in order to ob-

tain full advantage of a grooving insert’s chip-form-

ing abilities, the chip must be allowed to ow into the

chip-former. is chip-ow can be achieved by either

decreasing the workpiece’s surface speed, or increasing

the feed – more will be said on this shortly. e former

technique of decreasing the surface speed, allows the

material to move slower across the top rake of the cut-

ting edge and as a result, has greater contact time to

engage the chip-former. is slower workpiece speed,

has the benet of increasing tool life, through lower

33 A groove, or recess, can normally be considered as a straight-

walled recessed feature in a workpiece, as illustrated in Fig.

40. Typical applications for grooves are to provide thread re-

lief – usually up to a shoulder – so that a mating nut and its

washer can be accurately seated , or for retaining O-rings. As

the groove is produced in the workpiece, the tool shears away

the material in a radial manner, via X-axis tool motion. e

chip formed with insert geometries having a at top rake, will

have an identical width as the tool and can be employed to

‘size’ the component’s width feature. However, this chip action

– using such a tool geometry, creates high levels of pressure

at the cutting edge as a result of the chip wall friction, which

tends to produce a poor machined surface texture on these

sidewalls. Grooving with an advanced chip-former insert ge-

ometry, reduces the chip width and provides an ecient cut-

ting action, this results in decreasing the cutting edge pressure

somewhat. Chip-formers oer longer tool life and improved

sidewall nishes with better chip control, than those top-rakes

that have not incorporated such insert chip-forming geomet-

ric features.

tool/chip interface temperatures. e negative factors

of such a machining strategy, are that the:

•

Part cycle times are increased and as a result, any

batch throughput will be lessened,

•

As the cutting edge is in contact for a longer du-

ration, more heat will be conducted into the tool,

than into the chip, which could have a negative im-

pact of inconsistent workpiece size control,

•

Due to the lower workpiece surface speed, the ben-

ets of the insert’s coating will be reduced, as such

coating technology tends to operate more eec-

tively at higher interface temperatures.

(iii)

Increasing the feedrate – by increasing the feed

allows it to engage the chip-former more eectively

– this being the preferred technique for chip control. A

heavier applied feedrate, produces a chip with a thicker

cross-section. Further, a thicker chip engages the in-

sert’s geometry with higher force, creating a greater

tendency to break. Hence, by holding a constant work-

piece surface speed, allows the faster feedrate to reduce

cycle times.

Transversal, or Face Grooving

Transversal grooving geometry has a curved tear-

shaped blade onto which, the insert is accurately lo-

cated and positioned. e transversal insert follows

the 90° plunged feed into the rotating face of a work-

piece. ese tools are categorised as either right-, or

le-hand, with the style adopted depending upon

whether the machine tool’s chuck rotates anti-clock-

wise (i.e. using a right-hand tool), or clockwise (i.e.

le-hand). e minimum radius of curvature for such

transversal grooving tooling is normally about 12mm,

with no limit necessary on the maximum radial curva-

ture that can be machined. For shallow face grooves,

o-the-shelf tooling is available, but for deep angular

face grooves they require specialised tools from the

tooling manufacturers.

If a relatively wide face groove requires machining

with respect to the insert’s width, then the key to suc-

cess here, is establishing where in the face to make the

rst plunge. is initial face plunge should be made

within the range of the tool’s diameter, otherwise the

tool will not have sucient clearance and will ulti-

mately break. Successive plunges to enlarge the face

groove should be made by radially moving the insert

0.9 times the insert’s width, for each additional plunge.

e rotational speed for face grooving is usually about

80% of the speed used for parting-o – soon to be

Turning and Chip-breaking Technology

mentioned. Feedrates are normally around 50% of

parting-o values, with the proviso that for material

which is subject to work-hardening, minimum feeds

are necessary.

In transversal grooving operations, a unique chip

form occurs, because the chip is longer the further

away it is from the workpiece’s centre line of rotation.

is results in the chip which no longer ows in a

straight line across the insert’s edge, instead it moves

at an angle. Such a naturally curved chip is dicult to

exhaust from the face groove, particularly if it is bro-

ken. Hence, no attempt should be made to break the

chip. For deep and narrow grooves, the best solution

is to retract the tool at short intervals, to check that

the blade shows no signs of rubbing, this is to guard

against any likely breakage that might occur when

machining outside the blade’s range. Due to the fact

that transversal grooving tooling is susceptible to chat-

ter

34

, any excessive overhang of the tool should be mi-

nimised. e chip should never be allowed to become

entangled within the transversal groove and should be

ejected speedily, otherwise the tool is likely to break.

34 Chatter is a form of self-excited vibration and such vibrations

are due to the interaction of the dynamics of the chip-removal

process, together with the structural dynamics of the machine

tool. Such chatter, tends to be at very high amplitude, which

can result in either damage to the machine tool, or lead to pre-

mature tool failure. Typically, chatter is initiated by a distur-

bance in the cutting zone, for several reasons, such as:

Lack of homogeneity – in the workpiece material (i.e. typi-

cally a porous component, such as is found in a Powder

Metallurgy compact),

Workpiece surface condition (i.e. typically a hard oxide scale

on a hot-rolled steel component, utilsing a shallow D

OC

),

Workpiece geometry (i.e. if the component shape produces

either a variation in the D

OC

– for example, because of un-

even depth of casting material being machined, or light cuts

on interrupted shapes, such as hexagon, square, or rectan-

gular bar stock),

Frictional conditions (i.e. tool/chip interface frictional

variations, whilst machining).

Regenerative chatter is a type of self-excited vibration, result-

ing from the tool cutting a workpiece surface that has either

signicant roughness, or more likely the result of surface dis-

turbances from the previous cut. ese disturbances in the

workpiece surface, create uctuations in the cutting forces,

with the tool being subjected to vibrations with this process

continuously repeating, hence the term ‘regenerative chatter’.

Self-excited vibrations can be alleviated by either increas-

ing the dynamic stiness of the system, or by increasing the

damping.

NB Dynamic stiness can be dened as the ratio of the am-

plitude of the force to the vibrational amplitude.

–

–

–

–

For any face grooving of workpiece material that is

subject to a continuous chip formation, always use

copious amounts of coolant and at high-pressure – if

possible, to not only lubricate the cutting zone, but to

aid in chip ushing from this groove.

Parting-off

e parting-o process is normally considered to be a

separate machining operation, but it simply consists of

cutting a groove to centre of rotation of the workpiece,

to release it from the bar stock, or to ‘part-o ’ to a pre-

viously formed internal diameter (shown in Fig. 40 for

le-hand side operations). Essentially in a parting-o

operation, two time-periods are worthy of mention,

these are:

(i) At separation from the bar stock

– a lower spindle

speed than was previously used on the workpiece, will

prevent the ‘released part’ from hitting the machine

and potentially damaging its surface. Moreover, it al-

lows an operator – if present – to hear the change in

the lower spindle speed tone, as it is about to separate

from the bar stock, avoiding the parting-o tool from

getting ‘pinched’ between the stock and the soon-

to-be-released component. Oen, ‘Part-catchers’ are

utilised to reduce any surface damage to the falling

component, once it has been parted-o.

NB

If the component to be parted-o is held in a co-

axial/sub-spindle, at component release, the additional

spindle supports the workpiece and under these con-

ditions, the parting-o operation is virtually identical

to that of found in a grooving cycle.

(ii) Surface speed reduction

– this eectively oc-

curs when the machine’s spindle attains its maximum

speed. For example, on a machine tool having a maxi-

mum speed of 3,000 rpm, 90 m min

–1

would only be

achievable until the parting diameter has reached

about 8.6 mm. When parting to a smaller diameter

than 8.6 mm, the surface speed would decrease at a

xed spindle speed. As the parting diameter reaches

5.8 mm the surface speed would be 55 m min

–1

, or 60%

of the ideal, thus signicantly increasing the chip load-

ing as the tool approaches the workpiece’s centreline.

In order to alleviate the increasing tool loading, lower-

ing the feedrate by about 50% until separation is just

about to occur, then nally dropping the surface speed

to almost zero at this point, reduces the tendency for a

‘pip’ to be present on the workpiece. On a CNC driven

spindle, it is not advisable for parting-o operations,

Chapter

to utilise the ‘canned cycle’ such as the ‘constant surface

speed’

35

function.

NB

A more serious parting-o problem has been that

in order to eliminate the pip formed at the centre of the

‘released component’ , some tools have been ground

with the front edge angle of between 3° to 15°. Such

a front edge geometry, can introduce an axial cutting

force component, leading to poor chip control, which

in turn, causes the tool to deect. is parting-o tool

deection, can lead to the component’s face ‘dishing’ ,

creating a convex surface on one face and a concave

surface on the other – so this tool grinding strategy

should be avoided.

Today, parting-o inserts normally consist of two

main types with top rakes that are either of, negative,

or positive cutting edge chip-forming geometries. e

negative-style of chip-formers are possibly the most

commonly utilised. ese inserts have a small nega-

tive land at the front edge which increases the insert’s

strength, giving protection in adverse cutting condi-

tions, such as when interrupted cutting is necessary

during a parting-o operation. e land width – oen

termed a ‘T-land’ , is relative to the breadth of the part-

ing-o tool. is width of the insert’s land has a direct

correlation to the feedrate and its accompanying chip

formation. e feedrate must be adequate to force the

workpiece material over the land and into the chip-

former

36

.

Notwithstanding the widespread usage of negative

parting-o tooling, positive-style insert geometries

have some distinct advantages. e chief one being the

ability to narrow the chip at light feedrates, with mini-

35 ‘Constant surface speed’ CNC capability as its name implies,

allows the machine tool to maintain a constant surface speed

as the diameter is reduced. e main problem with using

this ‘canned cycle’ , is that as the maximum spindle speed is

reached, the chip load will also increase. is is not a prob-

lem, so long as the maximum speed has not occurred, such as

when parting-o a component with a large hole at its centre.

36 Parting-o operations that employ a negative-style insert (i.e.

with a land and accompanying chip-former), normally have

the feedrate determined in the following manner: by multi-

plying the width of the insert by a constant of 0.04. For ex-

ample, for a 4 mm wide tool, it is necessary to multiply the

insert’s width of 4 mm by 0.04 to obtain a feedrate of 0.16 mm

rev

–1

. is will give a ‘start-point’ for any parting-o opera-

tions, although it might be prudent to check this feedrate is

valid, from the tooling manufacturer’s recommendations.

mal tool pressure. If excessive tool pressure occurs,

this can promote work-hardening of the ‘transient

surface’

37

of the workpiece. ese abilities are impor-

tant points when machining relatively low mechanical

strength components, which might otherwise buckle

if machined with negative-style inserts when subse-

quently parted-o.

Positive cutting edge parting-o tooling having

chip-formers, are ideal for applications on machine

tools when either low xed feedrates are utilised, or

if the workpiece material necessitates lower cutting

speeds. is positive-style of parting-o tooling, oper-

ates eciently when machining soer workpiece mate-

rials, such as: aluminium-or, cooper-based alloys and

many non-metallic materials, typically plastics. Feed-

rates can be very low with these positive-type part-

ing tools, down to 0.0254 mm rev

–1

with exceptional

chip control and consistent tool life. One major dis-

advantage of using these positive tooling geometries

for parting-o, is that the tool is much weaker than its

equivalent negative geometry type.

e concept of insert self-grip in its respective tool-

holder, was developed by the cutting tool manufac-

turer Iscar tools in the early 1970’s and has now been

adopted by many other tooling manufacturers (Fig. 40

top le-hand side). ese ‘self-grip’ tooling designs,

rely on the rotation of the part and subsequent tool

pressure to keep the ‘keyed and wedged’ insert seated

in its respective toolholder pocket. Previously, double-

ended inserts termed ‘dogbones’ , were oen used but

were limited to low D

OC

’s – due to the length of the

secondary cutting edge, so have been somewhat over-

shadowed by the ‘self-grip’ varieties of parting-o

tooling.

.. Chip Morphology

The Characterisation of Chip Forms (Appendix 2)

In the now withdrawn ISO 3685 Standard on Ma-

chinability Testing Assessment, of some interest was

the fact that this Standard had visually characterised

37 Transient surfaces are those machined surfaces that will be

removed upon the next revolution of either the:

Workpiece (i.e in rotating part operations), or

Cutter (i.e. for rotating tooling – drilling, milling, reaming,

etc.).

–

–

Turning and Chip-breaking Technology

chip forms under eight headings, with several varia-

tions appearing in each groups (i.e. see Appendix 2

for an extract showing these chip form classications).

Although in the main, the chip forms were related to

turning, some of these chip morphologies could be ex-

trapolated to other manufacturing processes. e chip

type that will be formed when any machining opera-

tion is undertaken is the product of many interrelated

factors, such as:

•

Workpiece material characteristics – will the mate-

rial that forms the chip signicantly work-harden?,

•

Cutting tool geometry – changing, or modifying the

cutting insert geometries

38

and its plan approach

angles will have a major inuence on the type of

chip formed,

•

Temperatures within the cutting zone – if high, or

low temperatures occur as the chip is formed, this

will have an impact on the type of chip formed,

•

Machine tool/workpiece/cutting tool set-up – if

this ‘loop’ is not too rigid, then vibrations are likely

to be present, which will destabilise the cutting

process and aect the type and formation of chips

produced,

•

Cutting data utilised – by modifying the cutting

data: feeds and speeds and D

OC

’s, with the insert ge-

ometry maintained, this can play a signicant role

in the chip formed during machining operations.

NB Chip formation has become a technology in

its own right, which has shown signicant devel-

opment over the last few decades of machining ap-

plications.

As has been previously mentioned, chip formation

should always be controlled, with the resultant chips

formed being broken into suitable shape formation,

such as ‘spirals and commas’ , as indicated by the re

-

sultant chip morphology shown in Fig. 35a. Uncon-

trolled chip-steaming (i.e. long continuous workpiece

strands), must be avoided, being a signicant risk-fac-

tor to both the: machine tool’s operation and its CNC

setter/operator alike.

38 Chip-breaking envelopes (see Fig. 34 middle right), are the

product of plotting both the feedrate and D

OC

on two axes,

with their relative size and position within the graphical area

being signicantly aected by the cutting insert’s geometry

– as depicted by the three cutting insert geometric versions

shown by types: A, B and C (Fig. 34).

For every cutting insert geometry, there is a recom-

mended application area – termed its ‘chip-breaking

envelope’ (i.e. see footnote 38 below) – with regard to

its range of feedrates and D

OC

’s. Within this ‘envelope’ ,

chips of acceptable form are produced by the cut-

ting insert’s geometry. Conversely, any chips that are

formed outside this ‘envelope’ are not acceptable, be-

cause they are either formed as unbroken strands, or

are too thick and over-compressed. When component

proling operations are necessary (Fig. 31a), this nor-

mally involves several machining-related parameters:

variations in D

OC

’s, together with path vectoring of the

feeds and as a result of this latter point, changes to the

resultant chip’s path on the rake face. ese factors are

important as they can modify the chip morphology

when proling operations include: recessed/undercut

shoulders, tapers and partial arcs, facing and sliding

operations with the same tool, together with many

other combined proled features. All of these opera-

tions make signicant demands on the adaptability of

the cutting insert’s geometry to eciently break the

chip.

In general, the cutting insert’s chip formation prin-

ciples are concerned with the chip-breaker’s ability to

create a chip form that is neither not too tight a curl,

nor too open.

If chip curling is too tight for the specic machin-

ing application, the likely consequences are for a chip

form creating:

•

‘Chip-streaming’ – producing long chip strands

that are undesirable, wrapping itself around the

machined surface of the workpiece with work-

hardened swarf and possibly degrading this ma-

chined surface, or may become entangled around

the various parts of the machine tool, which could

impede its operation,

•

Excessive heat generation – this can decrease tool

life, or be conducted into the machined part and

consequently may aect specic part tolerances for

the individual part, or could lead to modications

in the statistical variability

39

of a batch of parts,

39 Statistical variability in component production can cause

variations from one part to another, as the standard deviation

and mean changes, these important factors will be mentioned

later in the text.

Chapter

•

Increased built-up edge (BUE) formation – which

through ‘attrition wear’

40

may cause the risk of pre-

mature cutting edge failure.

When the chip curling is too open, this may result in

the following negative tendencies:

•

Poor chip control – creating an inecient chip-

breaking ability by the cutting insert,

•

Chip hammering – breaking down the edge and

causing it to crumble and as a result creating the

likelihood of prematurely failing,

•

Vibrational tendencies – aecting both the ma-

chined surface texture and shortening tool life.

Chip formation and its resultant morphology, is not

only aected by the cutting data selected, but will be

inuenced by the plan approach (i.e. entering) angle

of the insert. In most machining operations, they are

usually not of the orthogonal, but oblique cutting in-

sert orientation, so the aect is for the entering angle

to modify the chip formation process. e insert’s en-

tering angle aects the chip formation by reducing the

chip thickness and having its width increased with a

smaller angle. With oblique cutting geometry, the chip

formation is both ‘smoother and soer’ in operation as

the plan approach angle tends toward say, 10° to 60°,

furthermore, the chip ow direction will also advanta-

geously change with the spiral pitch increasing.

As the nose radius is changed with dierent cutting

inserts, this has the eect of changing both the direc-

tion and shape of the chips produced. is nose radius

geometry is a fundamental aspect in the development

of chips during the machining process – as depicted by

Fig. 35b. Here, an identical nose radius and feedrate

is utilised, but the dierence being the D

OC

’s, with a

shallow D

OC

in Fig. 35b (le), giving rise to a slow chip

helix, whereas in Fig. 35b (right) the D

OC

is somewhat

deeper, creating a tighter chip helix which is bene-

cial to enhanced chip-breaking ability. Shallow cutting

depths produce ‘comma-shaped’ chip cross-sections,

40 Attrition wear is an unusual aspect of tool wear, in that it is

the result of high cutting forces, sterile surfaces, together with

chip/tool anity, creating ‘ideal’ conditions for a pressure

welding situation. Hence, the BUE develops, which builds-up

rapidly and is the ‘swept away’ by the chip ow streaming over

the top rake’s surface, taking with it minute atomic surface lay-

ers from the tool’s face. is continuous renewal and destruc-

tion of the BUE, enhances crater wear formation, eventually

leading to premature cutting edge failure.

having a small angle when compared to the cutting

edge. Equally, a larger depth means that the nose ra-

dius has somewhat less aect from its radius and

greater inuence by the entering angle of the cutting

edge, producing an outward directed spiral. Feedrate

also aects the width of the chip’s cross-section and its

ensuing chip ow

41

.

Chip formation begins by the chip curving, this be-

ing signicantly aected by combinations of the cut-

ting data employed, most notably: feedrate, D

OC

, rake

angle, nose radius dimensions and workpiece condi-

tion. A relatively ‘square’ cross-sectional chip nor-

mally indicates that an excessively hard chip compres-

sion has occurred, whilst a wide and thin band-like

chip formation is usually indicative of long ribbon-like

chips producing unmanageable swarf. If the chip curve

is tight helix, coupled to a thick chip cross-section,

this means that the length of the chip/tool contact has

increased, creating higher pressure and deformation.

It should be noted that excessive chip cross-sectional

thickness, has a debilitating eect on any machining

process. By careful use of CAD techniques coupled

to FEA to construct the insert’s cutting edge, comma-

shaped chips are the likely product of any machining,

providing that the appropriate cutting data has been

selected. In some machining operations, chip forma-

tion can be superior using a slightly negative insert

rake angle, thereby introducing harder chip compres-

sion and self-breaking of the chip, particularly if utilis-

ing small feeds. Conversely, positive rakes can be give

other important machining advantages, depending

which chip form and cutting data would be the most

advantageous to the part’s ensuing manufacture. Usu-

41 Chip-ow is the result of a compound angle between the chip’s

side- and back-ow. e chip’s side-ow being a measure of the

ow over the tool face (i.e. for a at-faced tool), whilst back-

ow establishes the amount of chip-streaming into the chip-

breaker groove. Detailed analysis of chip side-ow (i.e. via

high-speed photography), has indicated that it is inuenced

by a combination of groove dimensions and cutting data. If

the feedrate is increased, this results in a higher chip back-

ow angle, promoting chip-streaming into the chip-breaker

groove. e ratio of feed-to-length of restricted contact has

been shown to be an important parameter in the determina-

tion of chip- back-ow. Typically with low feedrates the cor-

responding chip back-ow is going to be somewhat lessened,

resulting in poor chip-breaker utilisation. When the restricted

contact between the chip and the tool is small – due to low

feed – the chip-ow does not fully engage the chip-breaker

and will as a result curve upward, with minimal ‘automatic’

chip-breaking eect.

Turning and Chip-breaking Technology