Lý thuyết điều khiển hơi và nước ngưng

Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (1.44 MB, 130 trang )

2.0

Section 2.0

Boiler controls and systems

Feedtanks 2.1

Steam injectors 2.2

Level controls 2.3

TDS blowdown controls 2.4

Conductivity sensors 2.5

Sample coolers 2.6

Conductivity meters 2.7

Heat recovery systems 2.8

Blowdown vessels 2.9

Vent heads 2.10

Bottom blowdown systems 2.11

2.0

Boiler controls and systems

2.1

2.1.1

2.1

TI-P401-25

AB Issue 2

Type DH

Flash Condensing Deaerator Heads

1

3

2

3

Head comprises

Item Quantity Description Material

1 1 Mixing Unit Austenitic

Stainless Steel

2 1 Immersion Tube Austenitic

Stainless Steel

3 2 Gasket Silicone Rubber

Application

Spirax Sarco Flash Condensing Deaerator Heads are ideal for

boiler feedtank applications. They are suitable for both new and

retrofit applications. Each head is fitted with a connection for air vent

and recirculating feedwater spray nozzle. The air vent is for the

immediate venting of liberated gases (the connection should also

include a vacuum breaker). For further details on the RFS recirculating

feedwater spray systems see separate literature.

A simple low cost solution for deaerating boiler feedwater at atmospheric pressure

l

Mixes hot and cold incoming flows

l

Liberates oxygen and other gases

l

Stainless steel for long maintenance free life

l

Easy to install

Description

Spirax Sarco flash condensing deaerator head is designed to mix

incoming flows of cold make-up, condensate return and flash steam

to the boiler feedtank. This mixing action is achieved by directing the

downward flow through a baffle arrangement within the unit. This

liberates dissolved gases from the cold make-up, which are vented

to atmosphere. The cold make-up inlet is fitted with a spray screen

which diffuses the flow, increasing its surface area to promote

thorough mixing with the condensate and flash steam.

A Spirax Sarco flash condensing deaerator head consists of three parts:-

— A mixing unit, which is bolted to the top of the tank and is

supplied with connections to customer specification for cold

make-up, condensate return , flash steam from blowdown etc.

— An immersion tube, which distributes the mixed fluids into the

tank and has an integral plate flange which is sandwiched

between the tank and mixing unit flanges.

Immersion tubes are fully described in separate literature.

— Gaskets. Two gaskets are required, one fitted each side on

the immersion tube flange. They are ordered separately.

Available types

The mixing unit is available in five nominal diameters (DN150,

DN200, DN250, DN300, DN400) flanged to BS 4504 PN 16 or BS

1560 Class 150.

Immersion tubes are available in diameters to suit the deaerator

heads and lengths of 950, 1200, 1600 and 2100mm to suit TM

metric feed tanks. Since each deaerator head is built to suit specific

plant requirements we recommend that your local Spirax Sarco

Engineer is contacted for a connection layout sheet and to discuss

your requirements.

Selection table

Total steam Mixing Tank depth

generation Unit 1250 1500 2000 2500

rate (kg/h) DN Mixing unit/immersion tube selection

5000 150

MU 150 MU 150 MU 150 MU 150

IT-950 IT-1200 IT-1600 IT-2100

10000 200

MU 200 MU 200 MU 200 MU 200

IT-950 IT-1200 IT-1600 IT-2100

20000 250

MU 250 MU 250 MU 250 MU 250

IT-950 IT-1200 IT-1600 IT-2100

30000 300

MU 300 MU 300 MU 300 MU 300

IT-950 IT-1200 IT-1600 IT-2100

50000 400

MU 400 MU 400 MU 400 MU 400

IT-950 IT-1200 IT-1600 IT-2100

Limiting conditions

PN 2.5 rating. Suitable for saturated steam 1 bar g, 120°C.

The mixing unit only is hydraulically tested to 2 bar g.

ISO 9001

Feedtanks

2.1

2.1.2

2.1

TI-P401-25 AB Issue 2

Centre line of

connections for

cold make-up,

condensate return,

blowdown flash steam, etc.

65 mm

Connection for recirculating

feedwater spray nozzle

100 mm

Flange for mounting on feedtank

B

A

20 mm

Connection for air vent/

vacuum breaker

How to specify

Atmosperic deaerator head in austentic stainless steel consisting of

mixing unit, immersion tube, and two gaskets. DN 150/200/250/300/

400. Flanged BS4504 PN 16/BS 1560 Class 300.

How to order

To specify a 150mm flash condensing deaerator head flanged

BS 4504 PN 16 (mixing unit plus immersion tube and gaskets to suit

a 1250 mm deep feedtank):-

MU 150 - PN 16

IT 150 - 950 PN 16

2 off gaskets to suit IT 150 - 1200 PN16

Connection details also need to be specified.

Dimensions

(approximate) in millimetres

Mixing Unit

Type A B Weight

MU150_ 175 484 30 kg

MU200_ 200 522 50 kg

MU250_ 220 557 65 kg

MU300_ 250 617 90 kg

MU400_ 290 680 125 kg

For details of immersion tube and gaskets see separate literature.

Boiler controls and systems

2.1

2.1.3

2.1

TI-P401-08

AB Issue 2

Type RFS

Recirculating Feedwater Spray Systems

l

Increases Flash Steam Condensing Capability

l

Improves Thermal Efficiency of the Feedtank

l

Improves Deaeration Within the Feedtank

l

Energy Saving Three Speed Pump

Limiting conditions

The system is designed for pumping water up to 100°C from an

atmospherically vented tank. Max ambient temperature 80°C.

How to specify

1 - Spirax Sarco Recirculating Feedwater Spray System RFS 1

V

1

2

3

1

4

General description

Spirax Sarco recirculating feedwater spray systems type RFS are

designed to provide additional flash steam condensing capacity on

boiler feedtank applications. When the condensate return flowrate is

high and the cold make-up flowrate is intermittent it is likely that

valuable flash steam will be lost through the vent. To ensure that this

flash steam is condensed it is often worthwhile to take feedwater

from a relatively cool part of the feedtank and pump it to a spray

nozzle. Approximately 20% of the feedtank content can be circulated

per hour to provide this additional flash condensing capacity. By

using a low energy pump the thermal efficiency of the feedtank can

be improved.

Available types

Two systems are available: RFS 1 and 2. Each system comprises:

Item Part Material

1 Isolating Valve Carbon steel with stainless steel internals

2 Y-Type Strainer S G Iron with stainless steel screen

3 Electric Pump Cast Iron with stainless steel internals

4 Spray Nozzle Stainless steel

Equipment details

System Isolating Y-Type Spray

Type Valve Strainer Pump Nozzle

RFS 1 Model 10 Figure 12 RP1 1" BSP Male

1" BSP 1" BSP 1" BSP Taper

240V

50Hz

RFS 2 Model 10 Figure 12 RP2 1" BSP Male

1¼” BSP 1¼” BSP 1¼" BSP Taper

240V

50Hz

Application

Systems type RFS are specifically designed for use with Spirax

Sarco Flash Condensing Deaerator Heads. The mixing unit of each

head is fitted with a connection for the spray nozzle.

Selection

A system is selected based on circulating approximately 20% of the

feedtank contents.

Gross Feedtank Recirculating Feedwater

Contents Spray Systems

Litre (kg) Designation Speed Setting

_ 3000 RFS 1 1

3000 to 6000 RFS 1 2

6000 to 8000 RFS 1 3

8000 to 10,000 RFS 2 2

10,000 to 30,000 RFS 2 3

Feedtanks

2.1

2.1.4

2.1

TI-P401-08 AB Issue 2

75

55

186

130

133

82

52

180

271

32

130

Pump Type RP2

Pump Type RP1

Existing

Drain Valve

To Recirculating

Pump Suction

New

Drain Valve

140 mm

28 mm

Dimensions

For details of Isolating valve Model 10 refer to separate literature.

For details of Y-Type strainer Figure 12 refer to separate literature.

Spray Nozzle

A specially designed stainless steel nozzle for distributing the

recirculated feedwater within the flash condensing deaerator head.

Screwed 1" BSP taper male. K

v

= 6.65.

Pump

Three speed induction rotor.

BSP union suction and discharge connections.

Single phase 240v 50 Hz.

System Connection Input Mass

Pump Power

Type Watts kg

RP1 1" BSP Union 40 to 100 2.5

RP2 1¼” BSP Union 85 to 100 2.5

Installation

For new applications

For new applications a specific connection should be incorporated

into the feedtank design. This connection should be the same nominal

size as the pump and should be positioned as near as possible to

the bottom of the tank. The suction side isolating valve, strainer and

pump should be positioned as near to the tank as possible whilst

allowing access for operating the ball valve and removing the strainer

screen. The discharge side pipework should be as short in length as

possible. On RFS 2 systems the discharge pipework should be

reduced to 1" at the spray nozzle.

The pump must be wired in accordance with The Electricity at Work

Regulations, that is, using a direct on line (DOL) starter fitted with a

thermal overload plus local isolator.

For retrofit applications

Where no suitable spare connection is available it is recommended

that the drain connection be utilised by fitting a tee-piece as follows.

It should be noted that the tank does not need to be drained to fit

these pieces.

Caution

For all applications the pump shaft must be horizontal, or slightly

higher at the vent plug end to prevent premature wearing of the top

bearing and shaft.

Operation

The pump should run continuously when the boiler(s) is on load.

Water should flow through the pump at all times while the pump is

running.

Maintenance

At convenient regular intervals it is recommended that the strainer

screen is inspected and any debris removed.

Boiler controls and systems

2.1

TI-P401-07

AB Issue 2

Immersion Tube

Materials

1 Immersion Tube Austenitic stainless steel

2 Gaskets Silicone Rubber

(May be coloured natural, white or red)

How to specify

1 - Immersion Tube IT150-950 in austenitic stainless steel

to suit DN150, PN16 flanges complete with

2 - Silicone rubber gaskets to suit DN150, PN 16.

A simple and effective means of distributing condensate return into boiler feedtanks

l

Easy to install

l

Stainless steel for long maintenance free life

l

Minimises water hammer

General description

The Spirax Sarco Immersion Tube is designed to distribute condensate

return into feedtanks to ensure efficient distribution of hot condensate.

Available types

Available as types IT100

_

, 150

_

, 200

_

, 250

_

, 300

_

and 400

_

with

an integral inside bolt circle sandwich flange to suit BS1560 or

BS4504. They are available in lengths to suit TM metric feedtanks.

Other lengths are available upon request.

Immersion tubes are designated by IT followed by DN followed by

length of immersion tube in mm. e.g. IT250-1600 is DN250 and is

1600mm long from the underside of the flange. It is suitable for a

2000mm deep tank.

Capacity

* Gravity

Condensate Pumped

(with 5% Flash) Condensate

IT type DN kg/h kg/h

IT100_ 100 1 015 2 500

IT150_ 150 2 285 5 000

IT200_ 200 4 065 10 000

IT250_ 250 6 350 20 000

IT300_ 300 9 145 30 000

IT400_ 400 16 255 50 000

* For other quantities of flash steam the capacity may be determined

pro rata i.e. for 10% flash capacity is half that shown.

As a general rule the size of an immersion tube should be at least

one DN larger than the condensate return main.

Limiting conditions

PN2.5 rating. Suitable for condensate at up to 1 bar g, 120°C.

Application

Spirax Sarco Immersion Tubes are ideal for boiler feedtank

applications. They are suitable for both new and retrofit applications.

They offer a much neater and more convenient solution to distributing

condensate return than traditional sparge pipes. Additionally they

reduce the common problem of water hammer found in sparge pipes.

This is achieved by slowing down the flow of the condensate return,

in particular any flash steam, as it enters the immersion tube with its

larger cross sectional area. This gives an opportunity for the flash

steam to pass through the holes into the feedtank without creating

sudden shocks.

When combined with a Mixing Unit they form a flash condensing

deaerator head. For further details see other literature.

1

2

2

2.1.5

ISO 9001

Feedtanks

2.1

TI-P401-07 AB Issue 2

Diameter D

6 to 10 mm

3 mm

Immersion

Tube

Each Immersion

Tube has a number

of holes in a

particular pattern to

suit the stated

capacity

Gasket

Immersion

Tube

Gasket

Top of Tank

Pipe to BS 1600

Schedule 5, 10 or 40

Alternatively,fit vacuum

breaker here, as near to the

elbow as possible.

Ideally fit vacuum breaker

here

Use a blind flange of same

DN as tank connection and

drill hole to suit DN of

condensate return main.

Dimensions Installation

Ideally the immersion tube should be positioned in the middle of the top

of the tank.

The immersion tube can be fitted to a boiler feedtank by the

following methods:-

(1) Using an existing nozzle on the tank top.

The immersion tube is designed so that it can pass through a nozzle

with dimensions according to BS 1600 schedule 40. The sandwich

flange of the immersion tube is equal to the raised face diameter of the

flange for which it is suitable. Gaskets are to be placed above and

below the sandwich flange.

This method is advantageous for feedtanks where no sparge pipes are

fitted since the immersion tube can be inserted without the need for

pipework modifications. Even where perhaps sparge pipes (or the

remains of!) exist, they could be removed and existing pipework utilised.

(2) On new installations a specific connection should be incorporated,

as specified on literature.

It is essential that a vacuum breaker is fitted to the condensate return

main near to the immersion tube. Consider the use of a Spirax Sarco

vacuum breaker VB14. Literature available on request.

Diameter R

Gasket (to be

installed prior to

passing immersion

tube through nozzle)

L

Dimensions

(approximate) in millimetres

Type D R for PN16 R for Class 150

IT100_ 100 162 157

IT150_ 150 212 216

IT200_ 200 268 270

IT250_ 250 320 324

IT300_ 300 378 381

IT400_ 375 490 470

L

IT

___

950 950

IT

___

1200 1200

IT

___

1600 1600

IT

___2100 2100

IT Type Weight (kg)

100-950 7

100-1200 9

100-1600 11

150-950 10

150-1200 12

150-1600 16

200-950 13

200-1200 16

200-1600 21

200-2100 28

250-1200 20

250-1600 27

250-2100 35

300-1200 24

300-1600 32

300-2100 42

400-1200 29

400-1600 39

400-2100 51

2.1.6

Boiler controls and systems

2.1

TI-P409-04

AB Issue 2

WG2

Water Level Gauge

•

Simple gauge glass for low pressure duties

•

Recommended for boiler feedtank applications

•

Available in lengths up to 2200mm

•

Supplied in modular form for maximum versatility

Description

The Spirax Sarco WG 2 level gauge enables an instant visual

check to be made of liquid level in tanks and process vessels.

It consists of a glass tube (plastic also available) mounted in top

and bottom support arms, with packing seals and washers to

prevent leakage and accommodate expansion. The bottom arm

incorporates a three port plug cock to allow isolation and checking

of gauge operation.

An intermediate arm provides additional support and sealing for

gauges with centres longer than 1100 mm, and enables two unequal

length tubes to be used together to give a wide choice of overall

lengths.

Two protector rods mounted either side of the tube reduce the risk

of accidental damage. For greater protection 'C' section protectors

are also available (used with rods).

Limiting conditions

Glass Plastic tube

Maximum working pressure (Pmax) 6.9 bar g 2.0 bar g

Maximum working temperature (Tmax) 152°C 134°C

Maximum saturated steam conditions 4.1 bar g 2.0 bar g

Cold hydraulic test pressure 13.8 bar g 3.0 bar g

Available lengths

(approximate) in millimetres

WG 2 level gauge glasses are designated WG2 followed by /

(centres dimension). Protector rods (in sets of two) and 'C' section

protectors are available in 700, 800, 1000 and 1100 mm lengths.

Two sets are required for gauges with intermediate arms. The

glasses themselves are available in four lengths which may be

paired in the following combinations to give the gauge centre

dimensions below:-

Glass 1 Glass 2 Intermediate Gauge Designation

length length arm centres

686 - No 700 WG2/700

786 - No 800 WG2/800

986 - No 1000 WG2/1000

1086 - No 1100 WG2/1100

686 686 Yes 1400 WG2/1400

686 786 Yes 1500 WG2/1500

786 786 Yes 1600 WG2/1600

686 986 Yes 1700 WG2/1700

786 986 Yes 1800 WG2/1800

786 1086 Yes 1900 WG2/1900

986 986 Yes 2000 WG2/2000

986 1086 Yes 2100 WG2/2100

1086 1086 Yes 2200 WG2/2200

Plastic tubes (complete with 2 off tube supports) are supplied in

1100 mm nominal lengths which can be cut to length with a knife.

2.1

2.1.7

ISO 9001

Feedtanks

2.1

An indication of the plug position is marked on the lever. We

recommend that the water connection is purged and the glass

drained periodically. It is important to check that water flows to drain

and that the level is rapidly re-established in the glass. A slowly

rising level could indicate a partial blockage.

Maintenance

No specific maintenance is required. We recommend that the arms

are checked for leakage periodically and the packing sleeves and

washers renewed if necessary. Always fit new packing sleeves and

washers if the tube has to be replaced.

Dimensions

(approximate) in millimetres

Weights

Top arm 0.65 kg

Intermediate arm 0.62 kg

Bottom arm 0.69 kg

Glass 0.145 kg /100 mm length

Protector rod 0.015 kg /100 mm length

'C' section protector 0.12 kg / 100 mm length

Plastic tube (1100 mm) 0.4 kg

Gland nut

Protector rod Ø4.8

Top plug

85

Gasket

Top arm

Washer

Seal

Washer

Glass

Ø12.7

Intermediate arm

Bottom arm

70

½" BSP Tr (R½)

52.5

¼" BSP Pl

(Rp¼)

Normal Drain glass

Purge water

82

Materials

No Description Material

1 Arm body Gunmetal BS 1400 LG2

2 Protector rods Brass BS 2874 CZ121

3 Glass tube Glass Borosilicate

4 Gland nut Brass BS 2874 CZ121

5 Top plug Brass BS 2874 CZ121

6 Plug cock Gunmetal BS 1400 LG 2

7 Packing sleeve Rubber Nitrile

8 Packing washer Permanite AF 2000

9 Top plug gasket Red fibre BS 216 Grade B

10 'C' section protector Stainless steel Type 304/304L

11 Plastic tube FEP

12 Tube supports Brass BS 2874 CZ132

(used with item 11) (Dezincification resistant)

Installation

WARNING

Your attention is drawn to Safety information leaflet IM-GCM-

10. Tanks or vessels must be drained, vented to atmosphere,

and inlets isolated before work is commenced.

In particular, make sure that any connections which could

carry hot fluids, for example condensate return or flash steam

from blowdown, are isolated.

Top, intermediate, and bottom arms have a ½" BSP taper male

thread (R½) for connection to the tank.

- The tank should have ½"BSP Pl (Rp ½) screwed sockets to take

the top and bottom arms, and intermediate arm if fitted.

Notes:-For certain lengths, the intermediate arm is not equidistant

between the top and bottoms arms. The socket for the intermediate

arm does not need to pierce the tank.

- Fit arms to tank using PTFE tape or a suitable jointing compound.

- Align arms vertically.

- Slacken all gland nuts and remove the

3

/

8

" BSP top arm plug and

gasket.

- Trim plastic tube to the required length (686, 786, 986, or 1086mm).

Each end of the tube requires an internal brass support, (supplied

with the tube).

- Sligthly flatten the ends of the tube with thumb and forefinger

before fitting the supports, to stop them moving during positioning.

- Pass glass/plastic tube through

3

/

8

" BSP thread in top arm and

lower into position.

When an intermediate arm is fitted, the ends of the two

glasses/tubes should touch and the joint should sit between the

intermediate arm glands.

- Gently tighten gland nuts and refit top arm plug and gasket.

- Fit the 'C' section protector (if used) to the front of the unit, then rotate

it so that its hooked edges line up with the protection rod drillings.

- Fit the protector rod(s) through the drillings in the top and

intermediate arms and locate in the blind drillings in the bottom

arm.

- Use the cutouts in the side of the protector to ensure the rods are

correctly positioned.

- The drain connection must not be plugged. It can either be left open

to a tundish, or may be piped to drain.

Operation

The plug cock has three positions:-

Up Purge water connection.

Horizontal Normal operation.

Down Drain glass. This position also isolates the water

connection in case of a broken glass.

Available spares

Glass 686 mm

Glass 786 mm

Glass 986 mm

Glass 1086 mm

Plastic tube (1100 mm) with 2 internal supports

Spare packing seal set consisting of:-

4 off Packing sleeves

8 off Washers (1 fitted each side of the sleeve)

2 off Top plug gaskets

The set is suitable for two re-packings of a gauge with no intermediate

arm or one re-packing of a gauge with an intermediate arm.

Order:- 1 spares pack for Water Level Gauge WG 2.

How to specify

Non-ferrous water level gauge with 3 port plug cock and protector

rods (and 'C' section protector), glass tubes/ plastic tubes.

How to order

Spirax Sarco WG 2/1000 water level gauge with 'C' section protector

and rods.

TI-P409-04 AB Issue 2

'C' section

protector

2.1

2.1.8

Boiler controls and systems

2.1

TI-P409-03

AB Issue 2

Dial Thermometers

General description

Spirax Sarco dial thermometers are reliable and robust instruments

which operate on the bi-metallic coil principle.

Two types are available:-

Austenitic stainless steel body, horizontal mounting, with glass

window. Optional pocket, with a 150mm extension to facilitate

lagging of the tank/vessel.

Aluminium body, vertical mounting, with glass window. Supplied

complete with brass slip-on pocket. Optional version with acrylic

window and stainless steel pocket.

Limiting conditions

Stainless body protection rating IP54

With or without pocket P max 25 bar g T max 120°C

Aluminium body

Maximum pressure P max 6 bar g T max 120/160°C

rating of pocket

Applications

Spirax Sarco dial thermometers are ideal for boiler feed tanks,

condensate pumping and many other industrial processes. Where a

pocket is installed it is possible to remove the thermometer without

draining the vessel contents.

Range

Stainless body 0-120°C

Aluminium body 0-120°C and 0-160°C

Accuracy

Stainless body Complies with DIN 16203 Class 1

Aluminium body Complies with DIN 16203 Class 2

Zero adjustment at pointer.

Dial Thermometer-

Stainless Steel body

Dial Thermometer-

Aluminium body

(supplied with pocket)

2.1

2.1.9

ISO 9001

Feedtanks

2.1

TI-P409-03 AB Issue 2

Installation

Screw the pocket into a ½" BSP connection on the vessel, using

PTFE tape as a thread sealant. The stainless steel dial thermometer

can be screwed directly into the vessel if required.

Position the thermometer so that it will measure a representative

temperature in the vessel. Vertical mounting thermometers have a

minimum insertion depth- see dimension 'H'. Heat conducting paste

is not normally necessary, but may be used if desired.

Materials

Stainless body Aluminium body

Bezel Stainless steel Stainless Steel

Window Glass Glass (acrylic optional)

Stem Stainless steel Brass

Pocket Stainless steel Brass (stainless optional)

How to specify

1 — Horizontal mounting dial thermometer with stainless steel wetted/

exposed parts, IP54 rating.

1 — Pocket with ½" BSPT thread (R½)

1 — Vertical mounting dial thermometer with slip-on pocket 0-120°C

range.

How to order

1 — Spirax Sarco dial thermometer, austenitic stainless steel,

horizontal mounting, 0-120°C.

1 — Pocket with 150mm extension for above.

1 — Spirax Sarco dial thermometer, aluminium body, c/w brass

pocket. 0-120°C range.

E

½" BSP Tr (R½)

F

H

G

I

½" BSP Pl

(G½)

Optional pocket (Stainless)

B

A

D

½" BSP Tr

(R½)

C

Thermometer (Stainless body)

A

B

D

E

F

C

G

H min

½" BSP Tr

(G½A)

Thermometer (Aluminium body) with pocket

Dimensions

(approximate) in millimetres

Stainless body

AB CDE FGHI

100 274 35 8 13 150 18 113 28

Weight Thermometer 0.25kg

Pocket 1.0kg

Aluminium body

A B C D E F G H min

100 48 16 174 35 160 13 65

Weight including pocket 0.4kg

2.1

2.1.10

Boiler controls and systems

2.2

TI-P401-05

AB Issue 6

IN15, IN25M, IN40M

Steam Injectors

• All stainless steel

• Ideal for boiler feedtank heating and de-aeration

• For efficient steam heating of water and other fluids

• Heats, mixes and circulates - no moving parts

• Compact design - minimises noise and vibration

IN15

A

1" BSP Taper or NPT male

BSP or NPT

female

Limiting conditions

Body design rating PN25

Maximum saturated steam condition 17 bar g at 207°C

Maximum heated liquid temperature

90°C

(tank/vessel vented to atmosphere)

Materials

Austenitic stainless steel grade 316L.

K

v

values

Injector IN15 IN25M IN40M

K

v

1.55 9.2 14.5

For conversion C

v

(UK) = K

v

x 0.97 C

v

(US) = K

v

x 1.17

How to order

1 - Spirax Sarco IN25M steam injector screwed 1" BSPT, austenitic

stainless steel grade 316L.

IN25M

IN40M

Description

Spirax Sarco steam injectors use steam to raise the temperature of

water or other liquids. They work by using a jet of steam to draw in

the liquid through radial ports, mix it, and distribute the heated liquid

throughout the tank or vessel. The circulation induced by the

injector ensures thorough mixing and avoids temperature

stratification. Three sizes of injector are available to suit a wide

range of applications.

The smallest, the IN15, has a male and a female thread for direct

mounting to a tank wall from the outside, or to pipework within

the tank.

The IN25M and IN40M are available in male thread or butt-weld

form and are fitted to pipework in the tank, or to a tank wall connection.

For higher capacities, two or more injectors may be mounted in

parallel.

Available types

The IN15 is supplied with a ½" female and 1" male thread, available

in BSPT or NPT.

Options for the larger injectors are shown below:-

IN25M IN40M

BSPT male 1" 1½"

NPT male 1" 1½"

Butt-weld 1" 1½"

Dimensions/weights

(approximate) in mm and kg

Type A B C Weight

IN15 ½" 205 28 0.4

IN25M 1" 84 71 0.8

IN40M 1½" 115 88 1.6

IN15

IN40M

(available screwed

or butt-weld)

IN25M

(available screwed

or butt-weld)

C

B

C

A

B

2.2.1

ISO 9001

Steam injectors

2.2

TI-P401-05 AB Issue 6

Capacity

- selecting a steam injector

The choice of steam injector depends on the flowrate of steam

required to heat the liquid. The table below shows steam injector

capacities in kg/h of injected steam when heating tanks are vented

to atmosphere, and are up to 3 metres deep. The choice of

control valve can affect the steam capacity.

For higher capacities use two or more injectors in parallel.

Injector type IN15 IN25M IN40M

System pressure Saturated steam

bar g capacity kg/h

1 20 135 400

2 48 175 580

3 66 280 805

4 84 350 970

5 102 410 1125

6 120 500 1295

7 138 580 1445

8 156 640 1620

9 174 700 1820

10 192 765 1950

11 210 830 2250

12 228 900 2370

13 246 975 2595

14 264 1045 2710

15 282 1095 2815

16 300 1170 3065

17 318 1225 3200

Installation

WARNING:- Your attention is drawn to Safety Information

Leaflet IM GCM-10. Full Installation and Maintenance

Instructions are provided with each unit. The reference notes

below do not contain sufficient information to install the

product safely, and any attempt to do so may be hazardous.

The injectors are installed at a low level in a tank, ideally along the

centre line, and discharging horizontally along the length. Pipework

may be routed inside or outside the tank. In all cases, steam supply

pipework must be firmly anchored to prevent vibration and stress in

the tank wall. We recommend the use of a suitable thread locking

compound on all threaded connections.

Use the same size pipe as the injector, i.e. 25 mm pipe for IN25M.

Pipe sizes for multiple injector installations are as follows:-

No. of

Type

Minimum

injectors pipe size

2 IN15 20 mm

2 IN40M 65 mm

3 IN40M 80 mm

Allow a minimum of 150 mm between the injector(s) and the sides

and bottom of the tank, and as much length as possible between

the injector outlet and the end of the tank. See IMI for minimum

limits. Space multiple injectors equally across the tank width.

System examples

The tables below give steam capacities for some typical injector /

valve / controller combinations for tanks vented to atmospheric

pressure. Intermediate values may be obtained by linear interpolation.

For alternatives or special applications refer to specific Spirax Sarco

literature or contact our sales engineers.

The tables below are examples only, and the valve / controller

combinations shown may not be available in all markets. Note: Steam

pressure at the injector will be much reduced and proper injection and

mixing may not occur if a smaller valve (or a larger injector) is fitted.

Self-acting control systems example

Injector type IN15 IN25M IN40M

Number off 121123

Valve type / size BX6 DN15 SB DN15 SB DN20 KB51 DN25 KC51 DN40 KC51 DN50

Valve K

v

1.65 2.58 3.81 9.8 16.48 34.0

Controller type

Self-acting control with 2 m capillary Self-acting control with 2 m capillary

Range 1. -20°C to 110°C Range 2. 40°C to 105°C

Steam supply

System saturated steam capacity kg/h

pressure bar g

2 47 82 110 350 580 1 150

4 78 140 200 550 1 000 1 750

6 109 195 280 750 1 400 2 525

8 142 236 360 1 000 1 750 3 200

10 171 310 450 1 200 2 075 3 800

12 201 365 - - 2 500 4 500

13 218 393 - - 2 675 5 000

Electric / pneumatic control systems example

Injector type IN15 IN25M IN40M

Number off 121123

Valve type / size

KE71 / KE73 KE71 / KE73 KE71 / KE73 KE71 / KE73 KE71 / KE73 KE71 / KE73

DN15 DN15 DN15 DN25 DN32 DN50

Valve K

v

1.6 4 4 10 16 36

Steam supply

System saturated steam capacity kg/h

pressure bar g

2 47 96 110 350 580 1 150

4 78 168 200 550 1 100 1 750

6 109 240 280 750 1 400 2 525

8 142 312 360 1 000 1 750 *

10 171 384 450 1 200 2 075 *

12 201 456 650 1 650 **

13 218 492 750 1 750 **

The information given in the tables is empirical and must not be used for critical applications. Use PN5123 or EL5601 actuator, EP5

positioner (PN), SX65 controller (available with mA output for PN actuator, or VMD output for EL actuator), EL2270 sensor and pocket, and

MP2 regulator.

* Consult your local Spirax Sarco sales engineer for information.

2.2.2

Boiler controls and systems

2.2

TI-P401-04

AB Issue 1

Type INS 6 and 10

Direct Steam Injection Heating Systems

A complete system for boiler feedtank, hot water storage and other process heating requirements.

l

Efficient and economic heating

l

Single seated valve giving tight shut-off

l

Simple installation

l

Stainless Seel injector for long life

l

Self-acting control valve requiring no external

l

Quiet operation

power

Optional isolating valve

and

'V' type strainer

General description

Spirax Sarco direct steam injection heating systems type INS are

designed to inject steam into tanks of water or process liquor to

ensure quiet and efficient heating of the tank contents. The injector

draws in cold liquid, mixes it with steam within the injector nozzle

and distributes the hot liquid throughout the tank. In many applications

the circulation induced by the injector is an advantage ensuring

thorough mixing and avoiding temperature stratification.

Available types

Systems are available as type INS 6 and 10, screwed BSP (BS21

parallel) or NPT.

Boiler feedtank applications

Oxygen must be removed from boiler water if corrosion is to be

prevented. Oxygen can be removed in two ways. Either, by the use

of oxygen scavenging chemicals or by thermal deaeration: the

dissolved oxygen content of water at 20°C is 9 ppm, at 60°C is

5ppm and at 90°C is just under 2 ppm. By heating the boiler feed

water typically to 80 - 85°C to remove the bulk of the oxygen and

using oxygen scavenging chemicals in the feeding after the tank the

use of chemicals can be reduced by up to 75%. Additionally, boiler

efficiency may be increased since blowdown requirements may be

lowered. The fitting of a dial thermometer on the tank is

recommended, a suitable product is available from the SPIRAX

SARCO range see TIS 10.9110.

System comprises

No. Part Material

1 Control Valve Bronze

2 Controller/Sensor Brass

3 Sensor Pocket Stainless steel

4 Injector Stainless steel

5 Vacuum Breaker Brass

Installation

Spirax Sarco direct steam injection heating systems are designed

to operate with the minimum of noise provided the installation is

correct. For full details refer to AIS 10.1406.

Regulations

Some installations will be covered by standard specification M & E

No. 3 (1986). M & E No. 3 clause 7.10.1 states that valve bodies up

to and including DN 50 used in steam systems shall be bronze. For

these applications Spirax Sarco Direct Steam Injection Heating

Systems are ideal.

How to specify

1 — Spirax Sarco Direct Steam Injection System type INS 6 screwed

BSP.

3

4

2

5

1

Please note: the mounting position

of the injector into the tank is drawn

out of position for clarity

2.2.3

Steam injectors

2.2

TI-P401-04 AB Issue 1

Capacities

System capacities in kg/h of injected steam when heating tanks vented to atmospheric pressure.

System Type INS 6 INS 10

Control Valve Size DN 15 with 6mm orifice DN 15

Steam supply pressure Capacities in kg/h of saturated steam

barg psig

229 47 82

3 44 63 110

4 58 78 140

5 73 94 168

6 87 109 195

7 102 125 223

8 116 142 236

9 131 155 282

10 145 171 310

11 160 186 338

12 174 201 365

13 189 218 393

Where steam supply pressures are higher consider the use of a pressure reducing valve or alternatively, the use of a combined pressure

reducing and temperature control valve. Please consult us for a suitable type.

Equipment details

System Type Control Valve * Controller Type and Range Sensor Pocket Steam Injector Vacuum Breaker

INS 6 DN 15 BX 6

128 with 2m capillary —

Stainless Steel — 1"

IN15 — 1 off

VB 14 — ½"

range 1 (-20 to 110°C) ½" female x 1" male

INS 10 DN 15 SB

128 with 2m capillary —

Stainless Steel — 1"

IN15 — 2 off

VB 14 — ½"

range 1 (-20 to 110°C) ½" female x 1" male

All equipment is available screwed BSP or NPT. * Control valves type BX6 and SB are normally open single seat valves.

Further details

(of associated equipment)

BX6 Control Valve TIS 1.800

SB Control Valve TIS 1.801

Type 128 Controller TIS 1.900

IN15 Steam Injector TIS 10.1411

VB14 Vacuum Breaker TIS 4.103

Fig 12 Y-Type Strainer TIS 7.401

Model 10 Ball Valve TIS 7.214

HV3 Stop Valve TIS 7.227

Dial Thermometer TIS 10.9110

A Y-type strainer is recommended upstream of the control valve.

The Y-type strainer should normally be the same size as the steam

supply pipeline. Consider a SPIRAX SARCO brass/bronze Fig. 12

(See TIS 7.401).

An isolating valve is recommended upstream of the Y-type strainer.

Consider the use of SPIRAX SARCO Model 10 Ball Valve in carbon

steel (See TIS 7.214) or the HV3 Stop Valve in bronze (See TIS

7.227).

2.2.4

Boiler controls and systems

2.2

TI-P401-03

AB Issue 2

Type INS

Direct Steam Injection Heating Systems

2.2.5

A complete system for boiler feedtank, hot water storage

and other industrial process heating requirements.

·

Stainless steel injector for long life and, with no moving parts is maintenance free

·

Self-acting system requiring no external power supply

·

Efficient and economic heating

·

Quiet operation

General description

Spirax Sarco INS direct steam injection heating systems are designed

to inject steam into tanks of water or process liquor to ensure quiet

and efficient heating of the tank contents. The injector draws in cold

liquid, mixes it with the steam within the injector and distributes the

hot liquid throughout the tank. In many applications the circulation

induced by the injector is an advantage ensuring thorough mixing

and avoiding temperature stratification.

Available types

Systems are available as type INS15, 20, 25, 40, 50, 65 and 80.

The injectors are for horizontal installation.

The selection of a system depends on the flowrate of steam required

to heat the tank contents and the steam supply pressure to the

control valve.

System comprises

No. Part Material

1 Control valve Bronze/gunmetal

2 Controller and sensor Brass

3 Sensor pocket Stainless steel

4 Horizontal injector Stainless steel

5 Vacuum breaker Brass

Boiler feedtank applications

Oxygen must be removed from boiler water if corrosion is to be

prevented. Oxygen can be removed in two ways, either, by the

use of oxygen scavenging chemicals or by thermal de-aeration.

The dissolved oxygen content of water at 20°C is 9 ppm, at 60°C is

5 ppm and at 90°C is just under 2 ppm. By heating the boiler

feedwater typically to 85-90°C to remove the bulk of the oxygen and

using oxygen scavenging chemicals in the feedline after the tank the

use of chemicals can be reduced by up to 75%.

Additionally, boiler efficiency may be increased since blowdown

requirements may be lowered.

Installation

Spirax Sarco direct steam injection heating systems are designed

to operate with the minimum of noise provided the installation is

correct.

How to order

Example: 1 off Spirax Sarco direct steam injection heating system

type INS15.

Stop valve

1

5

3

Y-type strainer

Dial

thermometer

2

4

Steam injectors

2.2

TI-P401-03 AB Issue 2

2.2.6

Capacities

System capacities in kg/h injected steam when heating tanks vented to atmospheric pressure.

System type INS15 INS20 INS25 INS40 INS50 INS65 INS80

Control valve Size ½" BSP ¾" BSP 1" BSP 1½" BSP 2" BSP 2½" BSP 3" BSP

Steam supply pressure

Capacities in kg/h of saturated steam

bar g psi g

2 29 87 110 350 580 1 150 2 500 3 700

3 44120 160 425 750 1 400 3 350 4 900

4 58150 200 550 1 000 1 750 4 200 6 000

5 73180 240 650 1 150 2 100 5 000 7 200

6 87215 280 750 1 400 2 525 5 800 8 400

6.9 100 237 316 840 1 535 2 800 6 500 9 450

7 102 240 320 850 1 550 2 950 6 600 9 550

8 116 275 360 1 000 1 750 3 200 7 400 10 700

8.2 118 278 370 1 020 1 780 3 280 7 550 10 950

9 131 290 410 1 100 1 900 3 600 8 200 11 850

10 145 315 450 1 200 2 075 3 800 9 000 13 000

10.3 150 325 460 1 230 2 135 3 920 - -

11 160 350 - - 2 275 4 200 - -

12 174 375 - - 2 500 4 500 - -

13 189 400 - - 2 675 5 000 - -

Where steam supply pressures are higher consider the use of a pressure reducing valve or alternatively, the use of a combined pressure

reducing and temperature control valve. Please consult Spirax Sarco for a suitable type.

Equipment details

System type Control valve type* Controller type Sensor pocket Steam injector Vacuum breaker

INS15 SB ½" BSP 128 with 2 m capillary

Range 1 S. Steel to suit 128 1 x IN25M

VB14 ½" BSP

-20 to 110°C 1" BSP 1" BSP

INS20 SB ¾" BSP 128 with 2 m capillary

Range 1 S. Steel to suit 128 1 x IN25M

VB14 ½" BSP

-20 to 110°C 1" BSP 1" BSP

INS25 KB51 1" BSP 128 with 2 m capillary

Range 1 S. Steel to suit 128 1 x IN40M

VB14 ½" BSP

-20 to 110°C 1" BSP 1½" BSP

INS40 KC51 1½" BSP 121 with 2 m capillary

Range 2 S. Steel to suit 121 2 x IN40M

VB14 ½" BSP

40 to 105°C 1" BSP 1½" BSP

INS50 KC51 2" BSP 121 with 2 m capillary

Range 2 S. Steel to suit 121 3 x IN40M

VB14 ½" BSP

40 to 105°C 1" BSP 1½" BSP

INS65 NS 2½" BSP 121 with 2 m capillary

Range 2 S. steel to suit 121 5 x IN40M

VB14 ½" BSP

40 to 105°C 1" BSP 1½" BSP

INS80 NS 3" BSP 121 with 2 m capillary

Range 2 S. steel to suit 121 7 x IN40M

VB14 ½" BSP

40 to 105°C 1" BSP 1½" BSP

*

Control valve type SB is bronze, single seat, normally open, direct acting.

Control valves type KB51 and KC51 are bronze, single seat, normally open, bellows balanced, direct acting.

Control valves type NS is gunmetal double seat, normally open, stainless steel trim, direct acting.

A Y-type strainer is recommended upstream of the control valve. The Y-type strainer should normally be the same size as the steam supply

pipeline. Consider a Spirax Sarco brass/bronze Fig. 12.

An isolating valve is recommended upstream of the Y-type strainer.

Consider the use of a Spirax Sarco carbon steel ball valve type M10 or bronze stop valve type HV2.

Boiler controls and systems

2.2

2.2.7

Steam injectors

2.2

TI-P401-06

AB Issue 2

Type SD

Steam Distributor

L

D

l

Simple installation — no special supports required.

l

Compact, lightweight and strong.

l

Stainless steel for long life.

l

Eliminates waterhammer.

l

Quiet operation.

General description

Spirax Sarco steam distributors type SD are designed to distribute

low pressure steam into tanks of water. They ensure rapid

condensation of the steam and efficient heating of the water. The

hole configuration provides a self-regulating control feature ensuring

that holes progressively come into use as the steam flowrate

increases. An internal stainless steel mesh ensures quiet operation.

Available types

SD40S, 50S and 80S screwed BSP (BS 21 parallel) or NPT.

SD80, 100 and 150 flanged to suit BS4504 PN16 or BS1560 Class

150.

Limiting conditions

Maximum saturated steam conditions 1.7 bar g 130°C

For quietest operation it is recommended that steam pressure is

reduced to below 1 bar g

Materials

Austenitic stainless steel.

Dimensions

(approximate) in millimetres

Steam Distributor Connection

Type D L

SD 40S 1½" BSP or NPT 100 70

Female

SD 50S 2" BSP or NPT 150 85

Female

SD 80S 3" BSP or NPT 215 110

Female

SD 80 80mm PN16 or 215 180

Class 150

SD 100 100mm PN16 or 235 210

Class 150

SD 150 150mm PN16 or 305 220

Class 150

Capacities

Each distributor has a number of holes. The flow of steam through

the holes depends on the differential pressure available. The table

below shows capacities in kg/h of distributed steam when heating

tanks which are vented to atmospheric pressure.

Steam Distributor

Steam Supply Type SD

Pressure bar g

40S 50S 80S & 80 100 150

0.2 99 176 396 643 935

0.4 135 240 540 877 1275

0.6 171 304 684 1111 1615

0.8 198 352 792 1287 1870

1.0 225 400 900 1462 2125

Intermediate values may be obtained by linear interpolation.

For higher capacities use 2 or more distributors in parallel.

Applications

1. Boiler blowdown heat recovery

Steam distributors type SD are ideal for supplementing the heating

of boiler feedwater tanks using flash steam. When used in conjunction

with a flash vessel, as part of a boiler blowdown heat recovery

system, flash steam recovery is simple, of low capital cost and is

maintenance free. Additionally, the flash steam is condensed to

pure water reducing the amount of make-up water and chemical

treatment required. Generally for sizing purposes use a differential

pressure of 0.4 bar.

2. Sparge pipes

Direct steam injection at low steam pressures has been traditionally

carried out using sparge pipes which are made from a length of

pipe. These have a disadvantage in that they must be made to suit

each and every application. However by utilising a more universal

design Spirax Sarco can offer a "steam distributor" that will suit most

applications. For higher steam pressures Spirax Sarco steam injectors

may be used.

Installation

Fit the end of a vertical downpipe in the tank so that the bottom of

the distributor is at about

1

/

3

of the working depth of tank. The piping

between the steam source and distributor should be the same

nominal size as the connection on the distributor. It is recommended

that the piping is less than 10m in length in order to minimise the

pressure drop.

How to specify

1 — Spirax Sarco steam distributor Type SD40S screwed 1½" BSP.

2.2.8

Boiler controls and systems

2.3

2.3.1

AI-P402-15

AB Issue 5

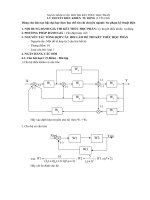

Tank Level Control (On/Off)

Power

Alarm

LC1300

Pump

Alarm

Description

The Spirax Sarco (on/off) tank level control system is suitable for most qualities of industrial waters where the electrical conductivity is greater

than 10 micro Siemens/cm or 10 ppm. The controllers should be mounted in an enclosure or panel to provide environmental protection. They

may be mounted on a 'top-hat' DIN rail using the mounting clip provided or the controller base may be screwed directly to a chassis plate.

Fig. 1 Pump fill with low level alarm

Power

Alarm

LC1300

Pump

Alarm

LC1300 controller

Pump

contactor

Pump

Pump off

Pump on

Low level alarm

LP10-4 probe

t

High level alarm

t

t

t

Applications

On/off tank level control can be achieved using the

Spirax Sarco LC1300 controller in conjunction with

LP10-4 level probes. The LC1300 controller is able to

provide the following functions:-

a) Pump-in control with low or high alarm or

b) Pump-out control with low or high alarm or

c) High or low alarm plus extra low alarm.

Typical arrangements

We recommend the probe is in a protection tube. The

metal tank generally forms the earth return. However,

where the tank is of a non-conductive material one of

the probe electrodes should be used to provide the

earth return.

Fig. 2 Valve control fill with low level alarm

Low level alarm

Valve open

Valve closed

Solenoid

valve

LC1300 controller

LP10-4 probe

High level alarm

t

t

t

t

Level controls

2.3

2.3.2

AI-P402-15 AB Issue 5

Power

Alarm

LC1300

Pump

Alarm

LC1300 controller

Pump contactor

LP10-4 probe

Pump

High level

Pump on

Earth return

Flow to process

Pump off

Fig. 4 Pump fill with high level alarm (with polypropylene tank)

Power

Alarm

LC1300

Pump

Alarm

LC1300 controller

High level

Glass lining

Alarm

Low level

LP10-4 probe

Earth return

Fig. 3 Tank alarms on glass lined vessel

t

t

t

t

t

t

Boiler controls and systems

2.3

Description

The system comprises a Spirax Sarco LP20 level probe and PA20 preamplifier together with either an LC2200 or LC2500 controller, and

associated valves and fittings, depending on the application.

Separate literature is available which explains the individual equipment in detail.

Applications

Spirax Sarco capacitance probe based systems can be used to monitor and control the level of a wide range of conductive liquids.

The controllers may be used in a variety of configurations for many different filling or emptying applications.

For modulating level control, Spirax Sarco supply a control valve with an electric actuator and 1000 ohm feedback potentiometer.

The LC2200 and LC2500 level controllers should be mounted in a metal or plastic enclosure to provide environmental protection. Spirax

Sarco are able to supply suitable enclosures.

Controllers may be mounted on a 'top hat' DIN rail using the mounting clip provided or the controller base may be screwed directly to a chassis plate.

If the tank or vessel contents are turbulent the probe should be mounted in a protection tube.

Typical arrangements

The system provides the following options:-

Modulating fill control with high alarm

Modulating fill control with low alarm

Using the LC2200 controller

Modulating empty control with high alarm

Modulating empty control with low alarm

On/off fill control with high alarm

On/off fill control with low alarm

Using the LC2500 controller

On/off empty control with high alarm

(with pump contactor)

On/off empty control with low alarm

(with pump contactor)

Examples of the many level control duties possible

AI-P402-16

AB Issue 4

Level Control (On/Off or Modulating)

using Capacitance Probes

Control valve

Make-up water

LP20 probe/

PA20 preamplifier

Low level alarm

Valve modulates to

maintain water level

within this band.

Condensate return

to boiler house

Pump

Pump off

Pump

contactor

Pump on

High level alarm

LP20 probe/

PA20 preamplifier

Fig. 1 Boiler feedtank make-up with modulating control

and low level alarm.

Fig. 2 Condensate return tank on/off emptying control

with high level alarm

LC2200 controller

LC2500 controller

t

2.3.3

Level controls

2.3

AI-P402-16 AB Issue 4

Control valve

Make-up water

Flow to process

Valve modulates to

maintain water level

within this band

LP20 probe/

PA20 preamplifier

Fig. 4 Drainage control of a large process pressure vessel;modulating control with high level alarm.

High level alarm

LC2200 controller

Control valve

To drain

LP20 probe/

PA20 preamplifier

High level alarm

LC2200 controller

Fig. 3 Process water tank with modulating fill control, and high level alarm

Valve modulates to

maintain water level

within this band

2.3.4

Boiler controls and systems

2.3

AI-P402-08

AB Issue 4

LCS1000

Level Control Systems - Chamber Mounted

2.3.5

Alarm

AlarmPower

LC1300

LC1300

Power

Alarm Pump

Typical installation

LCS1000 boiler level control systems are suitable for

automatically controlled steam boilers and provide the control

and alarm functions specified by British Standards in BS 2790, by

the Health and Safety Executive in PM5 and by SAFed (PSG2).

The LCS1000 systems require daily manual testing as specified in

PM5 and a trained boiler attendant should be on site at all times

the boiler is in operation.

The level controls and level alarms are probably the most important

controls on the boiler for ensuring safety and should only be

installed and maintained by suitably trained personnel.

Spirax Sarco can install, commission and provide a regular

maintenance service.

For details of installation, wiring and maintenance see the

Installation and Maintenance Instructions of the individual

components of the system.

Boiler

To drain tundish or

blowdown vessel

Chamber

Sequencing purge valves

LP10-4

probe

LP10-4

probe

High alarm

Pump off

Pump on

1st low

2nd low

Not used

Installation and testing

of on/off boiler water level controls in external chambers

Not used

LC1300 LC1300

Level controls

2.3

AI-P402-08 AB Issue 4

2.3.6

Daily test (or once per shift)

1. With the burner firing, operate the sequencing purge valve on the

1st low alarm chamber to purge through the water connection to

the chamber and to empty the chamber to drain. Check that the

burner shuts down and that the 1st low alarm lamp and bell

operates.

2. Return the sequencing purge valve to 'normal'. The alarm should

cancel and the burner refire.

3. With the burner firing repeat the test on the 2nd low alarm

chamber. The alarm should 'lockout' and should require manual

resetting before the burner will refire.

4. On completion of the test, check that all valves and controls are

in their normal operating position and that the water level is

correct in the level gauge glass. The boiler should not be left until

the person carrying out the test is satisfied it is operating

normally.

Weekly test

The weekly test should be carried out or witnessed by a responsible

person who appreciates the hazards involved and has been suitably

trained in the safe operation of the boiler and its controls. At no time

during the test should the water be lowered to the extent that it

disappears from the gauge glass.

1. With the feedpump switched off, allow the water level to fall by

evaporation until the burner shuts down at 1st low alarm.

2. Blow down the boiler until the 2nd low alarm sounds and the

burner controls go to lockout.

3. Raise the water level to normal, reset the lockout, then continue

to raise the water level to the high alarm level. Check that the

high alarm sounds.

4. Return all valves and controls to normal and monitor the boiler

until satisfied that it is operating normally.

Quarterly inspection

The Health and Safety Executive recommend from experience

that the boiler controls should be serviced at least at

quarterly intervals. Where the regular tests are carried out properly

in a well run boiler house with good water treatment, it may be

that only an annual inspection of the probes etc. is required.

This is a matter, however, for the user to decide in liaison with

his insurance company inspector in order to determine a

sensible inspection programme to suit the individual boiler plant.

We recommend a regular inspection as follows:

1. Inspect the probe plugs for moisture.

2. Unscrew the probes and wipe away any dirt from the probe

tips. If any hard scale is present it may be an indication of

more serious scale formation elsewhere in the boiler.

Investigate water treatment.

3. Remove the covers from the sequencing purge valves and

inspect the water connections to the boiler. Clean as necessary.

4. Inspect the wiring and controllers for damage.

5. Reassemble, refill the boiler and carry out a full functional check.